Doctoring

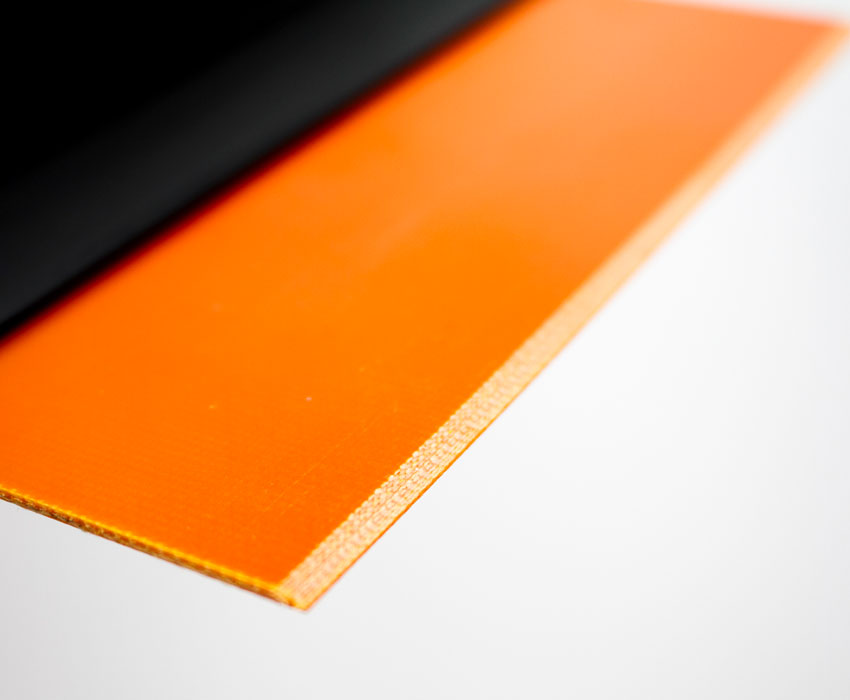

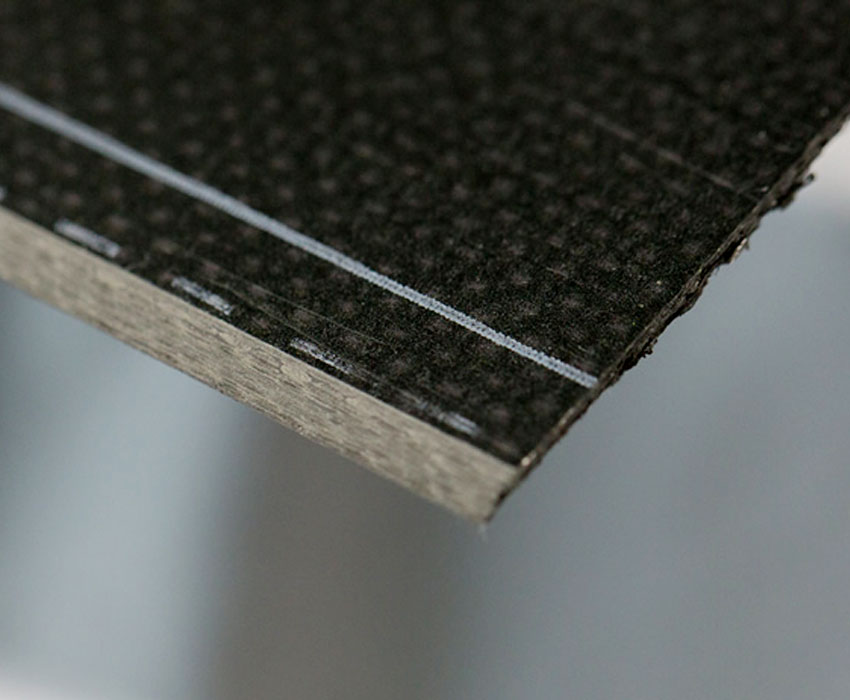

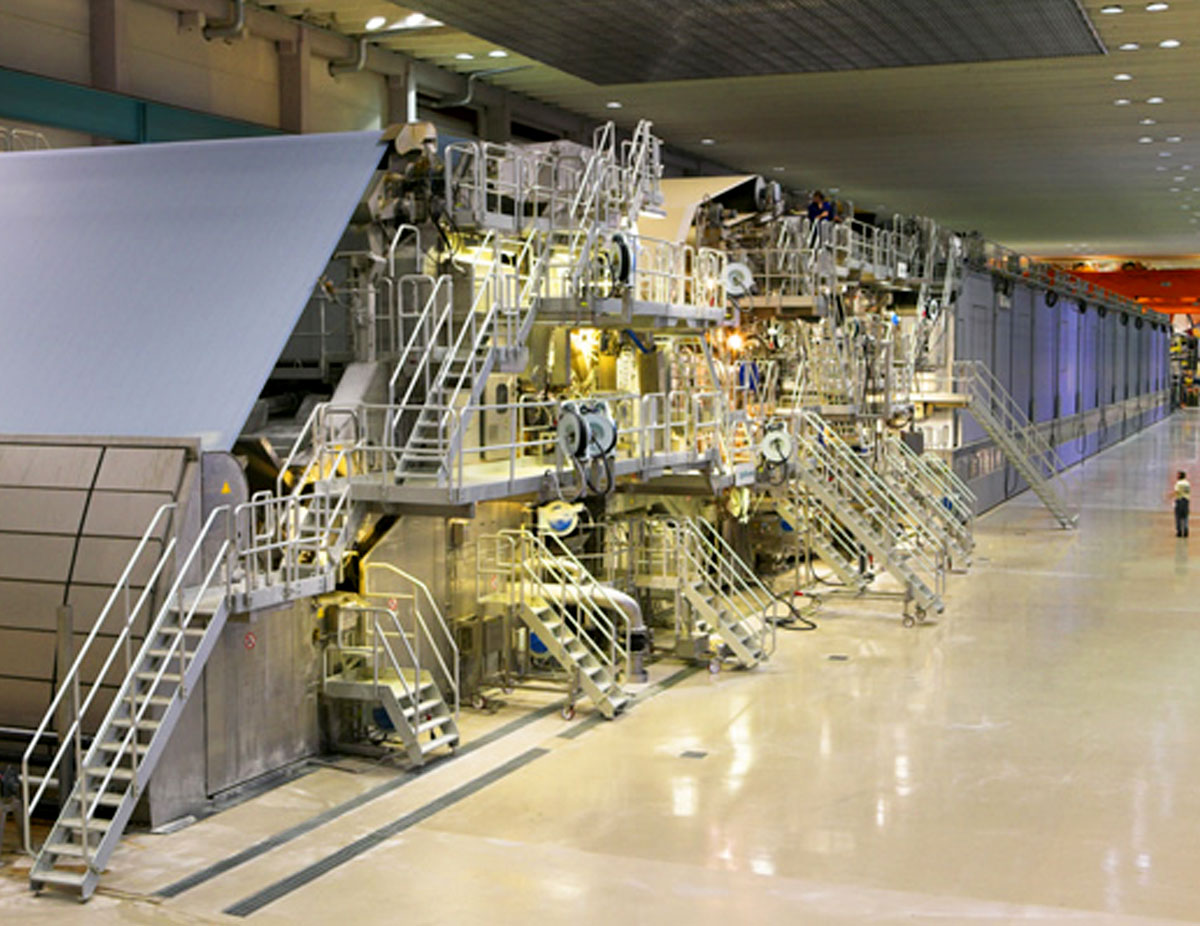

Doctoring? Roll cleaning? Scraping? Flaking? Continuous belt cleaning? These are terms for a similar process used differently depending on the industry, but the product’s purpose is the same–to clean or remove contaminants from a roll surface. A doctor blade, roll cleaning blade, scraper blade, or flaker blade is any material in stick form that is run against a roll and is used to keep the roll clean. Materials can be just about anything like composite, metal, or plastic.

-

Doctor & Roll Cleaning Blades

-

Nanotechnology-Enhanced Doctor Blades

-

Ceramic Tip Creping Blades

-

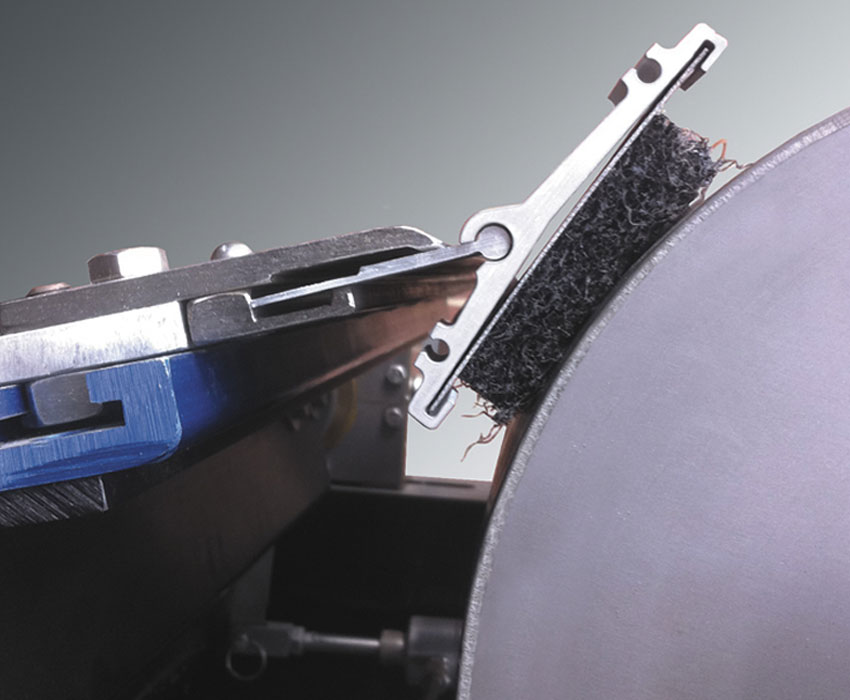

Doctor & Roll Cleaning Blade Holders

-

Roll Cleaner Assemblies

-

Double Doctoring Systems

-

Roll Polishers

-

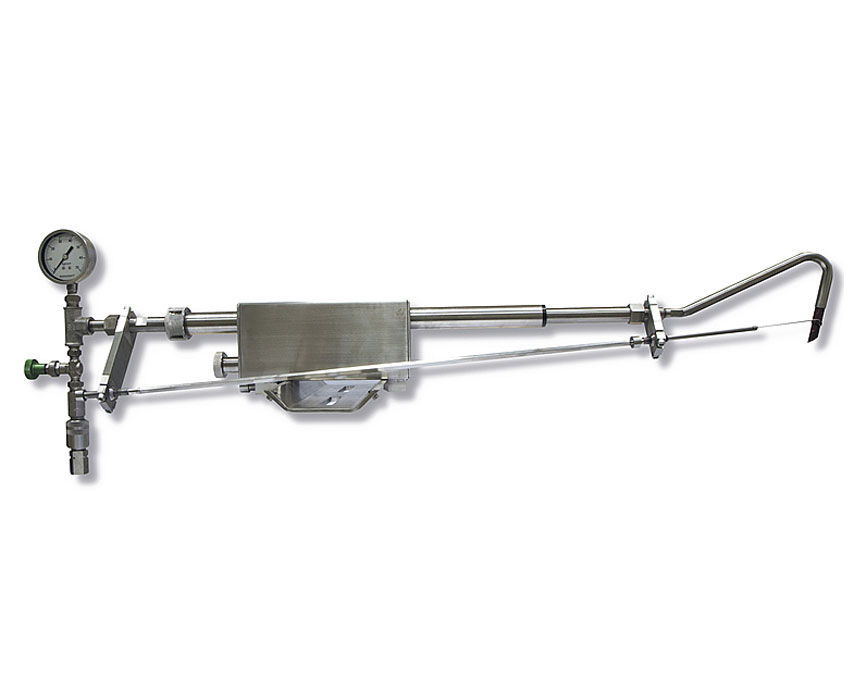

Oscillation Systems

-

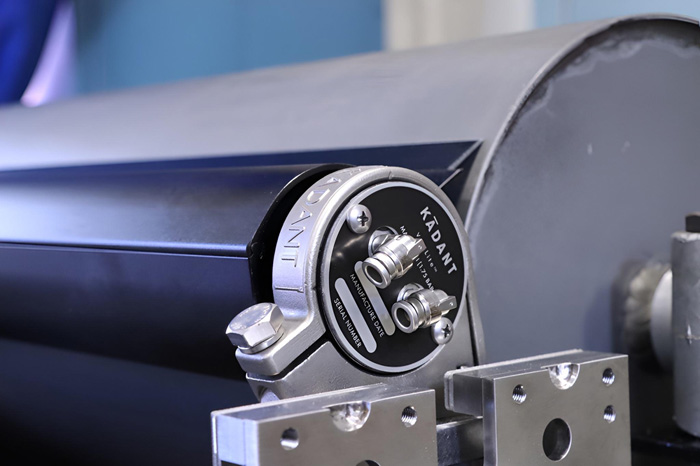

Split Doctor Bearing

-

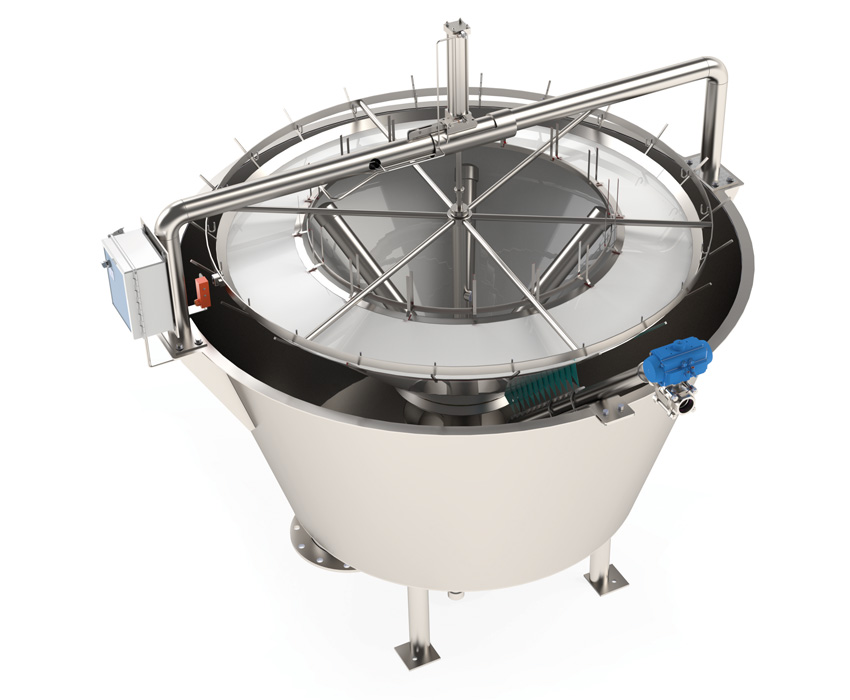

Yankee Dryer Cleaner

FAQ

-

How do I get the most out of my doctor or roll cleaning blades?

- Make inspecting blade and holder conditions a part of your maintenance routine.

- Change blades any time the machine is down for cleaning.

- Change the blade immediately any time there may be damage to the blade.

- Use a blade change indicator at the beginning of each blade change.

- Keep an inventory of commonly used blades to reduce downtime.

-

What happens when a doctor or roll cleaning blade wears?

As a blade wears into the roll, the area of the blade contact increases. Even though loading pressure remains unchanged, actual transmitted blade pressure decreases due to the surface contact area getting larger. Increasing loading pressure with a worn blade will greatly reduce the efficiency of the system and may allow material to pass under the blade and wrap the roll due to the additional deflection of the blade.

-

How do I know if oscillating a doctoring or roll cleaning system is right for my process?

If your process could benefit from better roll cleaning action, extended blade and roll life, increased sheet quality, and less chatter and dwell of the roll cleaning structure, an oscillating doctor system could be a significant advantage for your application.

-

Do I need to use Kadant doctor or roll cleaning blades in a Kadant doctor or roll cleaning holder?

Yes. Kadant has a genuine parts program backed by our technical blade experts. The Kadant genuine parts program focuses on employee safety, operating performance, and return on investment. Using Kadant blades is the only way to ensure the highest product quality and that integrity is maintained when using Kadant doctor holders.

Learn more about doctoring

-

Roll Cleaning is Critically Important to Milling or Flaking in Cereal Manufacturing

-

Inexpensive and Cost-Effective Doctor Solution for a Paper Machine

-

Nanotechnology and Doctor Blades

-

AccuFlake PRO Holder for Production of Baby Food

-

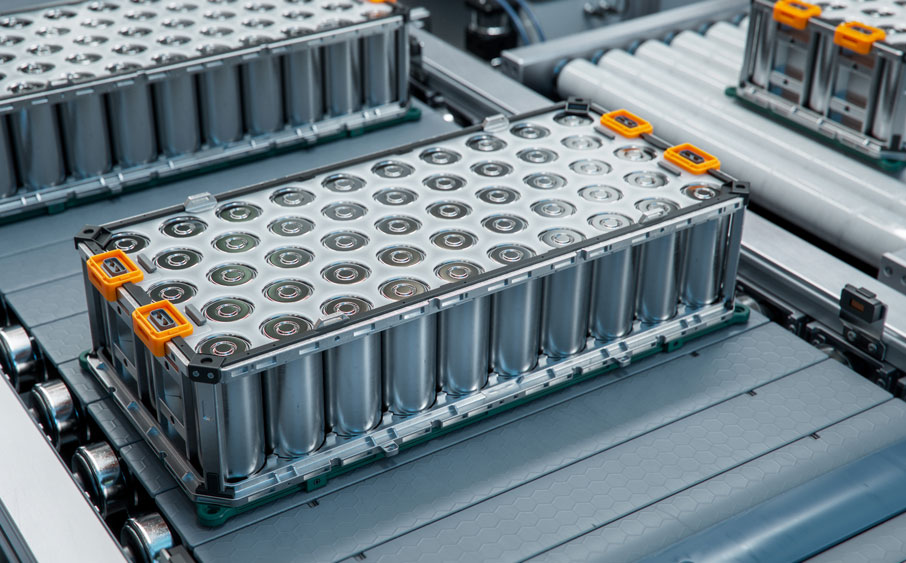

Kadant Supplies Roll Cleaning Systems to Electric Car Manufacturers for Battery Production

-

Roll Cleaning Solution for Contaminated Glass Veil Manufacturing

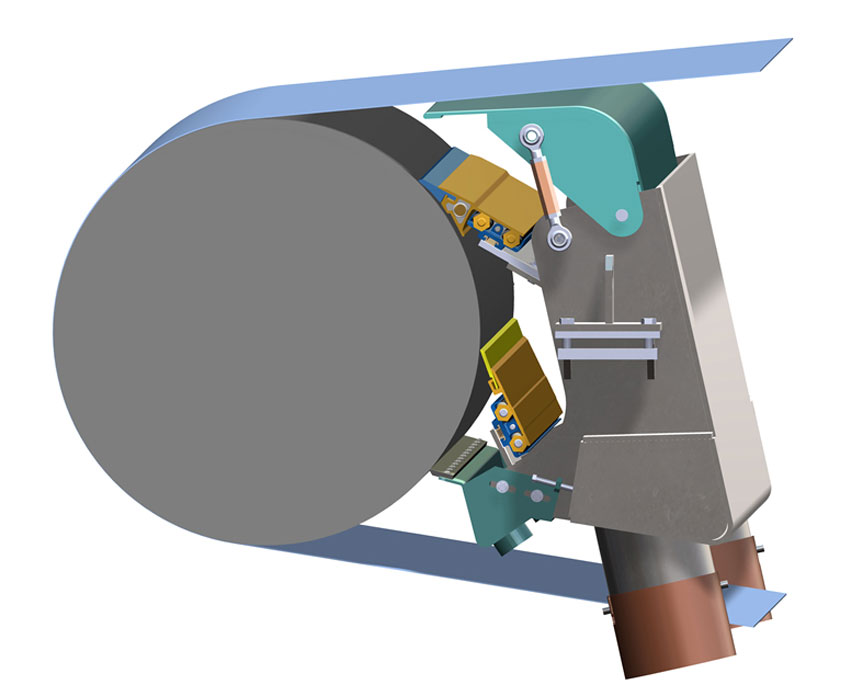

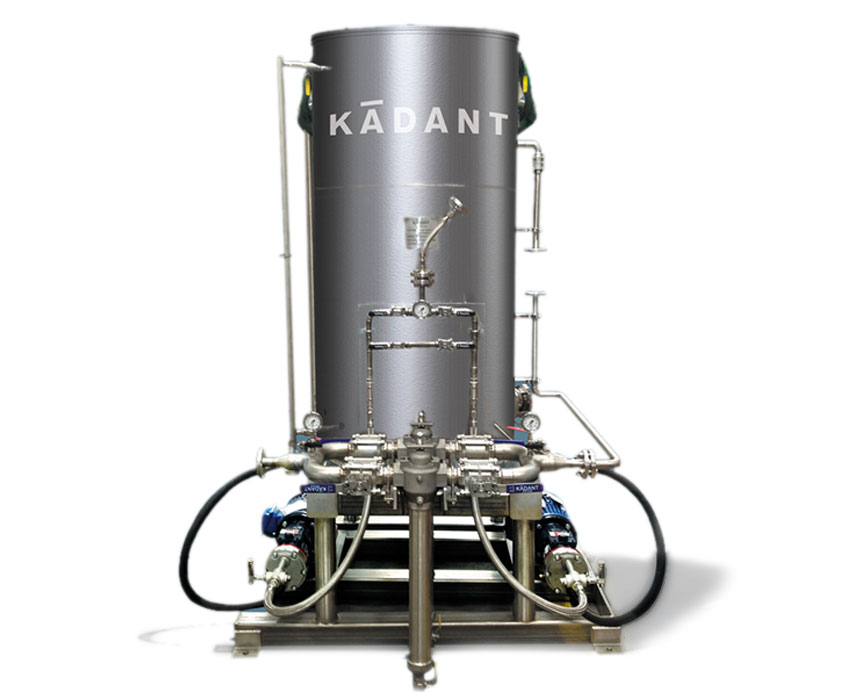

Roll cleaner assemblies are comprised of a roll cleaning blade, blade holder, structural beam, brackets, and bearings along with an option to oscillate.

Roll cleaner assemblies are comprised of a roll cleaning blade, blade holder, structural beam, brackets, and bearings along with an option to oscillate. A proper water resource recovery system can be essential for a variety of process industry applications, including the production of synthetic fibers.

A proper water resource recovery system can be essential for a variety of process industry applications, including the production of synthetic fibers.

is an important part of tissue manufacturing with several functions such as creping, dewatering, removing contaminants from fabric and felt carrier rolls, and cleaning and conditioning the Yankee dryer.

is an important part of tissue manufacturing with several functions such as creping, dewatering, removing contaminants from fabric and felt carrier rolls, and cleaning and conditioning the Yankee dryer.  Cleaning and conditioning products, such as the

Cleaning and conditioning products, such as the

products, such as pressure filters and resource recovery strainers, play a vital role in the molded pulp industry by removing contaminants from process water. These systems use

products, such as pressure filters and resource recovery strainers, play a vital role in the molded pulp industry by removing contaminants from process water. These systems use

The

The