Stock Approach Systems

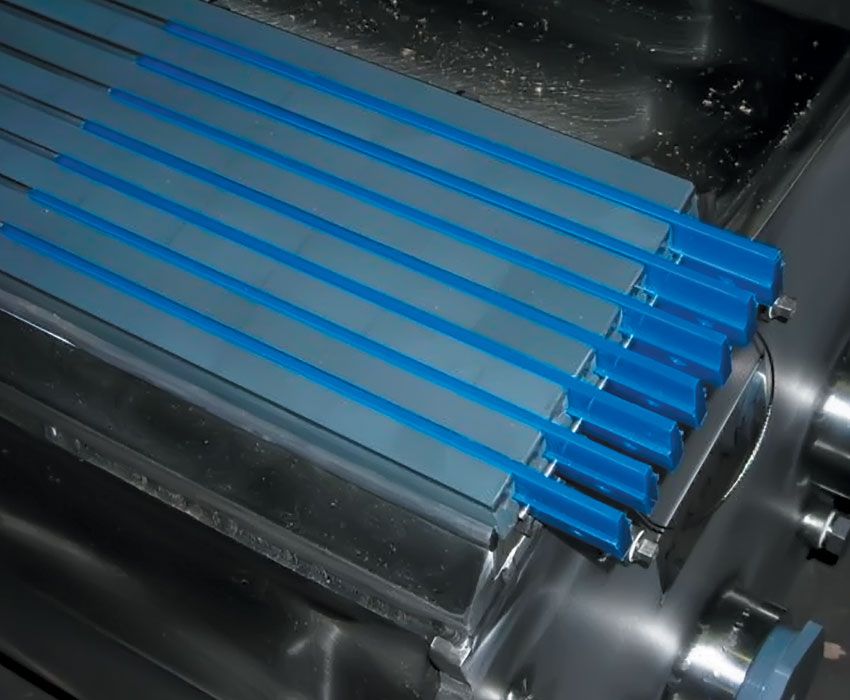

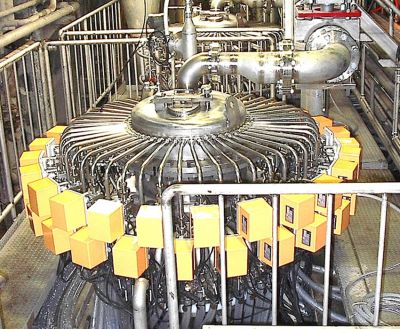

The Octopus™ stock approach system is a radial-type distributor that supplies forming devices (vats, hydraulic formers or headboxes) with uniform paper machine profiles across the width of the machine without the need for header balancing by recirculation.

When equipped with consistency profiling ability, the Octopus stock approach system allows the control of CD basis weight profile while paper machines are operating. The profile management tool permits the papermaker to minimize variations, improve sheet properties, and increase profitability.

Features

-

All wetted parts are stainless steel

-

Automatic air pad pressure compensation control

-

Optional CD consistency profiling

-

Applicable to headboxes, hydraulic formers, and vats

Benefits

-

Provides uniform CD flow/basis weight management

-

Does not require operator to balance unit in response to flow changes

-

Dampens pressure pulsation

-

Reduces entrained air

-

Reduces fiber floc size

-

Minimize variation

-

Improve sheet properties

-

Increase profitability

Related

FAQ

The Octopus stock approach system contains radial distribution and pressure pulse attenuator all in one unit. Other systems only have one of these features. Using the Octopus stock approach system leads to a much flatter profile across the paper sheet because the radial distributor and pressure pulse attenuator work together.

All applications and systems are unique, but typically, an Octopus stock approach system reaches a return on investment in less than one year.