R&D

Our state-of-the-art research and development facility is located in Auburn, Massachusetts. For over 40 years, our R&D has developed doctoring, roll cleaning, filtration, and water management process technologies for the pulp and paper, food, metal processing, carbon fiber, and many other industries.

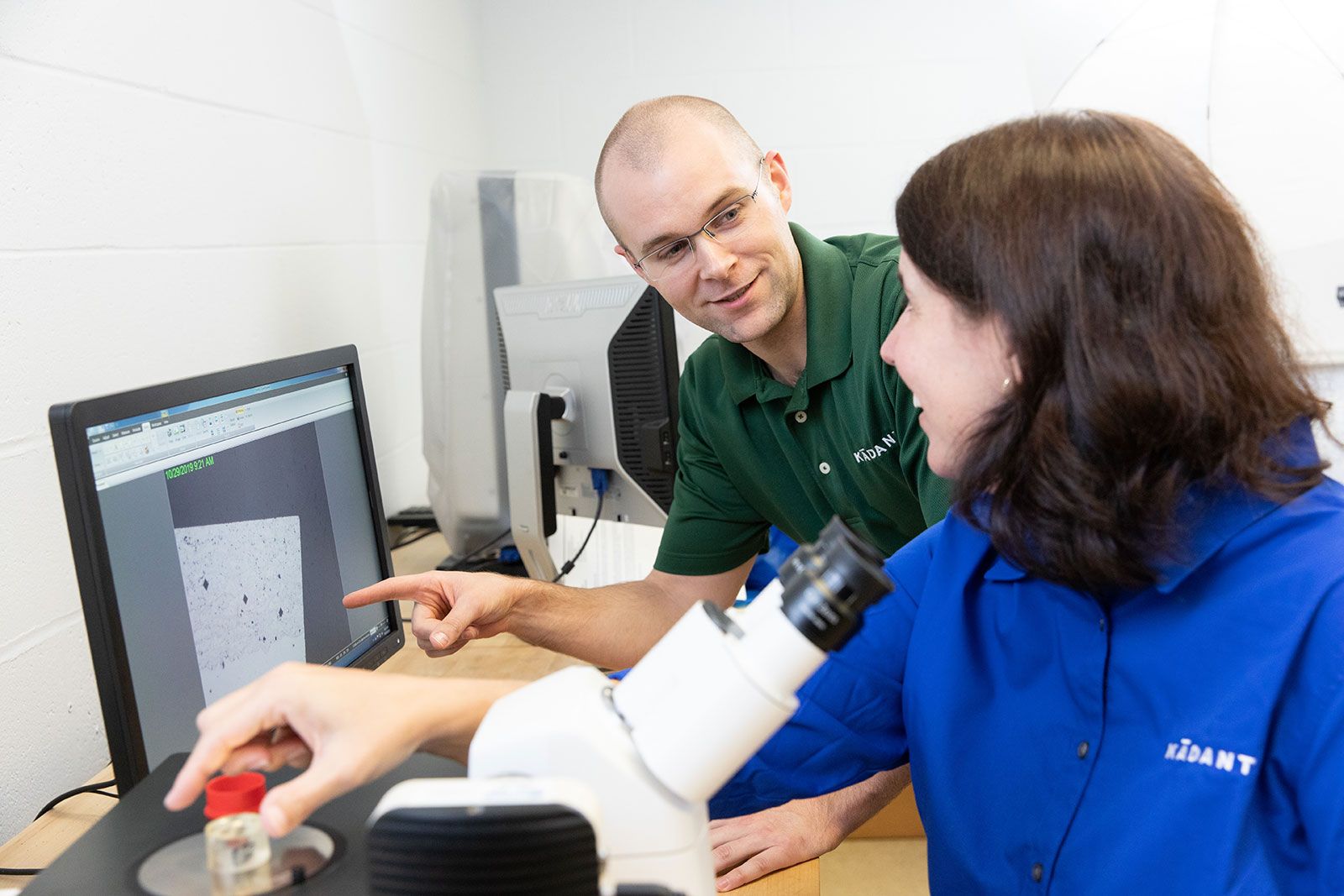

Metallography Lab

The metallography lab is furnished with the equipment from the industry leader in metallographic preparation. The lab is where the R&D team polishes and examines samples of our doctor and roll cleaning blade products. The primary purpose of the lab is to ensure the quality of ceramic and carbide-tipped creping blades, and to support the development of new coated tip blade technologies. The lab is equipped to check all important coating attributes such as hardness, porosity, un-melted particles, and other defects. The lab maintains a library of past evaluations to identify and correct process drift. The lab also supports special projects and other research and development activities.

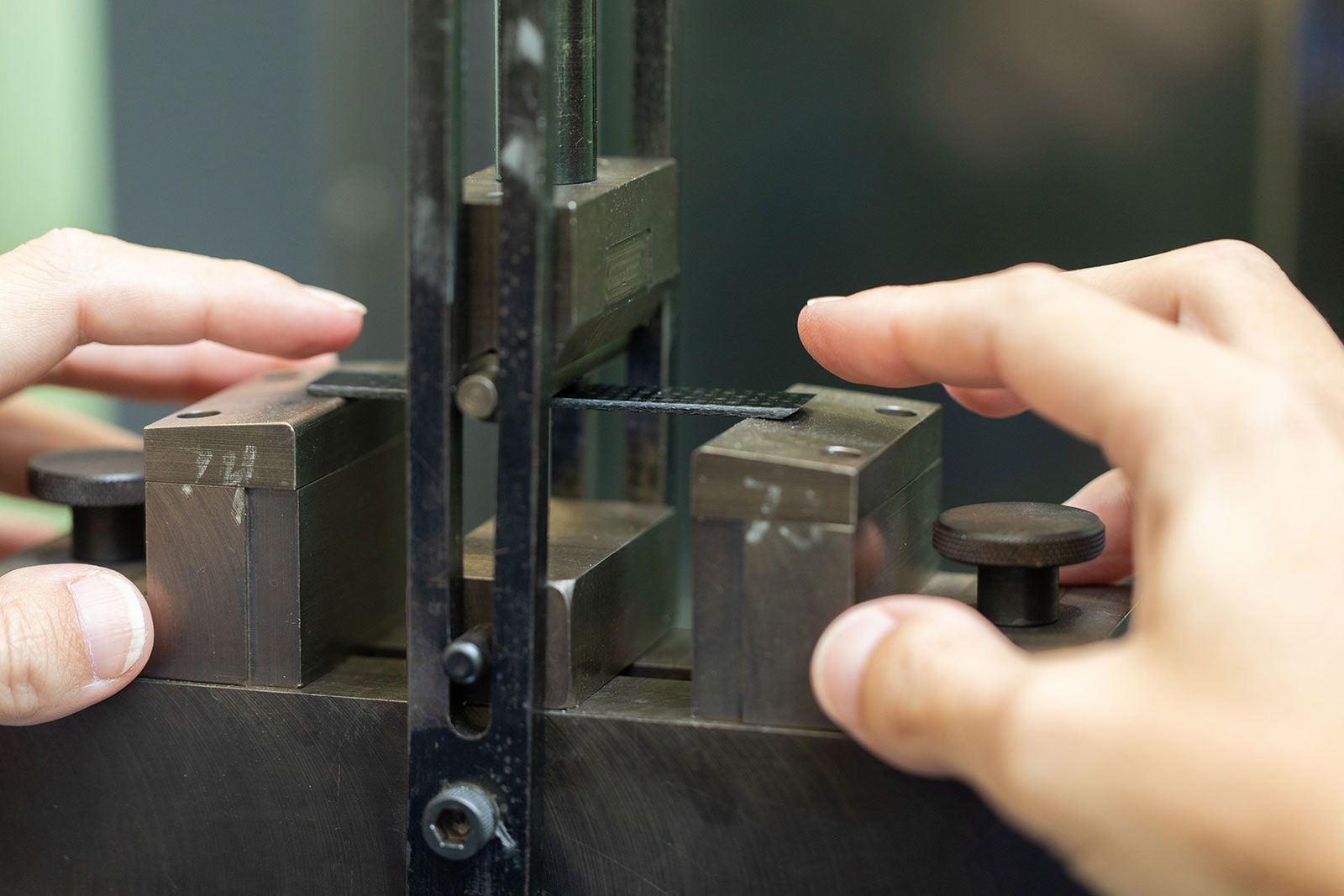

Material Testing Machine

The Instron material tester is used to perform tension, compression, flexural, creep, and peel tests at temperatures up to 400°F. The Instron is used mainly for blade materials but can also test other products Kadant Solutions offers. The data is used in the development of new products and for ensuring our products maintain the highest quality standards.

Blade Wear Tester

The blade wear test system can be used to evaluate both composite and metallic doctor and roll cleaning blade products. This test system is comprised of a rotating roll that can reach speeds of 10,000 FPM, load arms to precisely load doctor blade specimens against the roll surface, and integrated load measuring instrumentation. The in-house roll options include ceramic, composite, steel, and soft nip calender rolls.

Blade View™ Measurement Device

The Blade View measurement device was designed specifically for the tissue making industry. The device digitally analyzes the creping blade wear profile by measuring both angle and width across multiple points of a creping blade. The data is extracted to provide real-time feedback pertaining to important parts of the process including doctor profile and alignment. This portable device allows for fast, accurate measurements in the field.

Finite Element Analysis (FEA)

A design and research tool used to perform static, dynamic, thermal, and vibration analysis of doctor structures, doctor blade holders, and doctor blades.

Vibration Analyzer

The vibration analyzer provides important design information by measuring and analyzing vibration signals. It is used in the field to identify the source of problem vibrations on the paper machine.

Bauer McNett Water Test

The Bauer McNett device is used to test 5-gallon water samples submitted by customers. A series of tests can be conducted on the water to determine if it’s a viable application for one of Kadant Solutions’ filtration products.

The M-clean™ Cleaning System Research Facility

Kadant Nordic, located in Huskvarna, Sweden, is home to an M-clean™ cleaning system research facility and pilot plant. Numerous process industries such as papermakers, roofing manufacturing, and food processing are faced with the challenge of keeping fabrics and roll covers clean. Contaminants are deposited and consequently forced into the void volume of fabrics, reducing permeability, creating holes in the sheet, and other runnability issues. In addition, deposits on roll surfaces cause picking or sheet marking. These deposits can come from the raw material (recycled fiber), starch, coating paste, dust, oil, and grease and are often referred to as “stickies”.

Traditional cleaning methods are often incapable of dealing effectively with such contaminants or are undesirable due to the large volume of water required. At Kadant Nordic’s research facility and pilot plant ongoing studies are being conducted to better understand the challenges presented by contaminants and how those challenges can be addressed. Working closely with customers and fabric and chemical suppliers, Kadant Nordic is optimizing existing technologies and looking for new cleaning solutions.

Each trial opportunity is defined as one fabric from the customer. Multiple tests can be executed on just one piece of fabric. For example, the fabric is divided into sections. Each section is tested with different variables. Variables may include with vacuum versus without vacuum, low water pressure versus high water pressure, and cleaning with a few spray nozzles versus many spray nozzles.