A History of Innovation: Synthetic Fiber

Courtesy of the American Fiber Manufacturers Association / Fiber Economics BureauFor centuries, mankind has been captivated by the idea of creating fiber for specific purposes. Since the first synthetic fibers were produced around the turn of the 19th century, the industry has grown significantly. The vast majority of innovations have pertained to the chemistry involved in creating the raw materials. An industry of real modern-day alchemists!

Courtesy of the American Fiber Manufacturers Association / Fiber Economics BureauFor centuries, mankind has been captivated by the idea of creating fiber for specific purposes. Since the first synthetic fibers were produced around the turn of the 19th century, the industry has grown significantly. The vast majority of innovations have pertained to the chemistry involved in creating the raw materials. An industry of real modern-day alchemists!

Efforts to improve safety and production yield have also seen major developments. Wider and faster machines offer increased capacity, and safety interlocks and protocols have served to improve the operating environment.

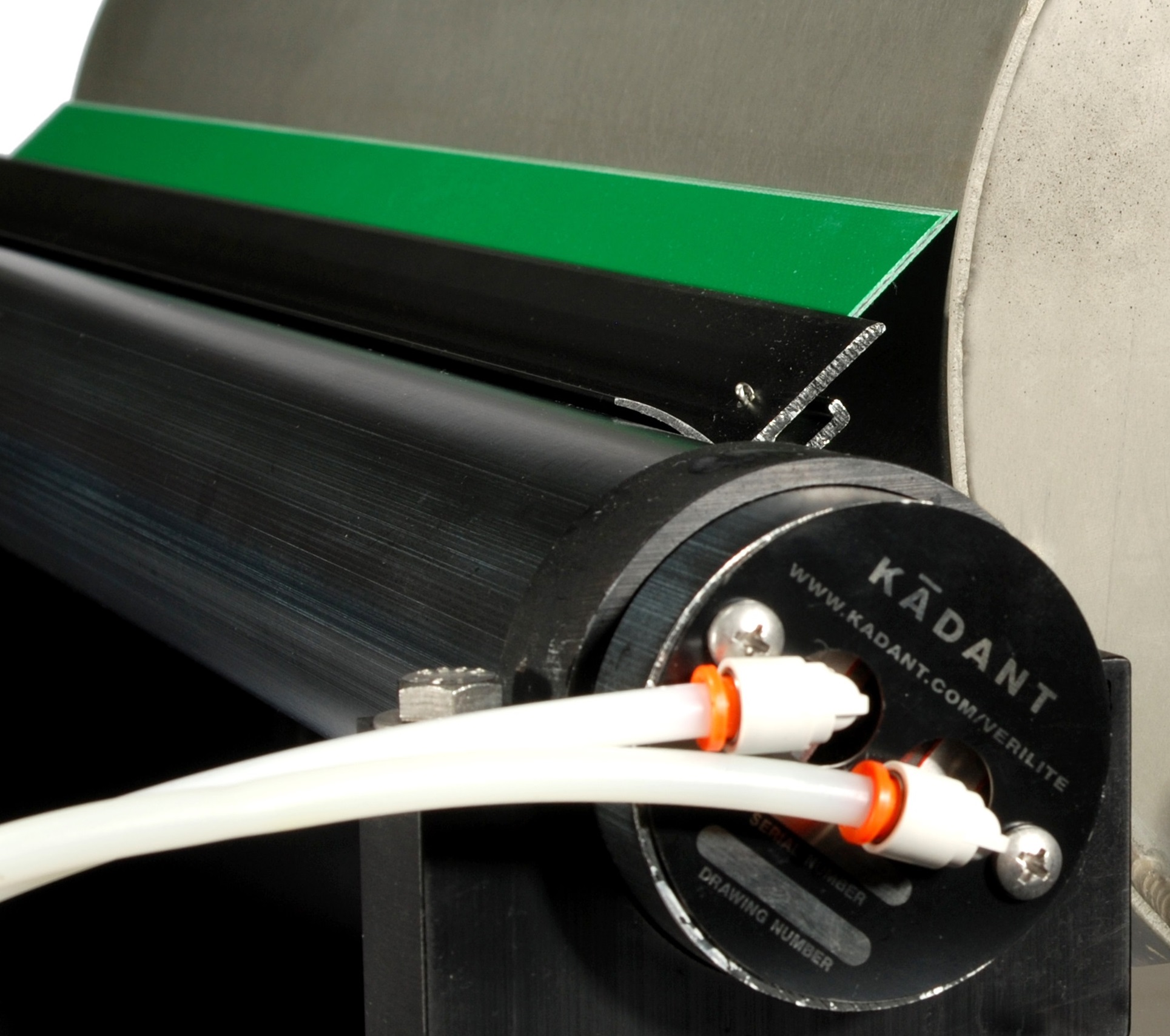

However, there are still potentially dangerous situations that operators can find themselves in when cleaning rolls and removing broken fibers from the machinery. To address these specific issues, Kadant Solutions designed an advanced roll cleaning solution that allows the user to safely manage fiber as it contacts and pulls across a roll or other rotating equipment.

The VeriLite™ roll cleaner assembly is the first integrated roll cleaning assembly designed specifically for improving yield and safety in the production of synthetic fiber-based products. The VeriLite roll cleaner assembly is designed to fit the narrow tolerances present in synthetic fiber manufacturing. Whether cantilevered like many stretching operations or simply supported like a variety of coating and finishing operations, the VeriLite roll cleaner assembly employs nearly 75 years of Kadant innovation to:

- Prevent broken fiber from wrapping rolls and reintroduces it to the fiber tow

- Provide continuous roll cleaning virtually eliminating the need for operator interaction with rotating machinery

- Produce lower roll drag when compared to other methods of continuous roll cleaning and wrap prevention

Since maintenance can be safely performed in a matter of minutes and without violating safety boundaries, it’s easy to see how this innovation in process equipment can increase machine uptime and produce greater yields.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.