Filtration

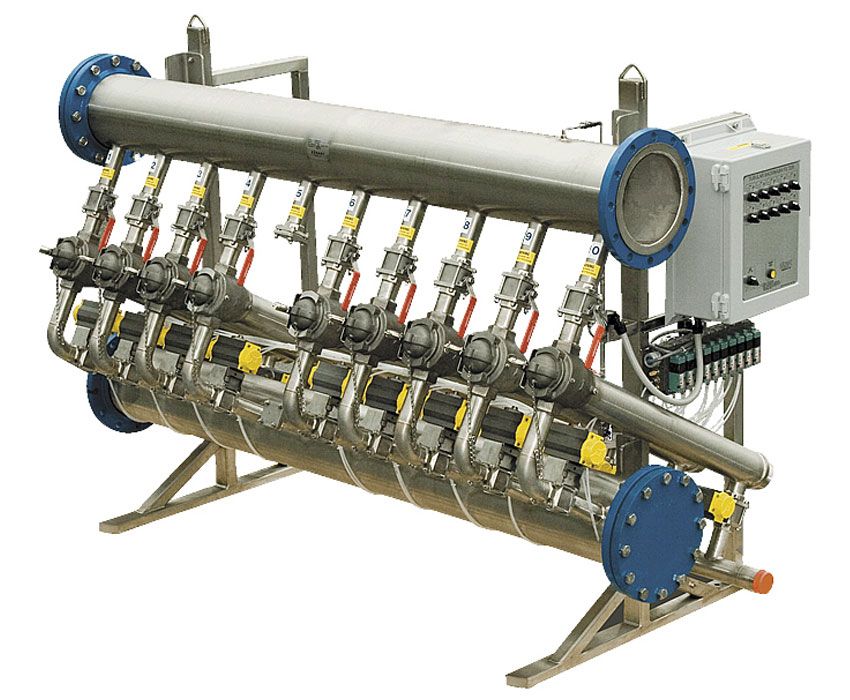

Filtration products, such as pressure filters and water resource recovery strainers, are used to remove contaminates from liquid in process industries. A filtration system will contain a filter media which is used to separate unwanted particles from the substance being filtered. The filtration process can be intermittent or continuous providing high cleaning efficiency and easy maintenance.

To maximize performance, filtration systems are chosen and designed for the application. Common applications include fresh water, process water recycling, dyes and additives, mechanical seal protection, chemicals, DAF filtrate, clearleg save-all water, overflow cylinder vat water, vacuum pump seal water, felt hair removal from press section, fiber recovery from u-drains, solids separation, thickening, fiber scalping, removal of sand from rivers and lakes, cooling towers, pump protection, steel mill water recycling, and spray nozzle protection.

FAQ

There are a couple common reasons why pressure liquid filters clog quickly. First, the process may be unstable and the solids loading becomes high. Alternatively, the process may have changed, or the filtration equipment isn’t installed in the correct place for the application.

This video shows step-by-step instructions for changing the RotoFlex resource recovery strainer filter media.

The EMO III oscillator is equipped with a service light to help with preventative maintenance. Watch this video to learn more.