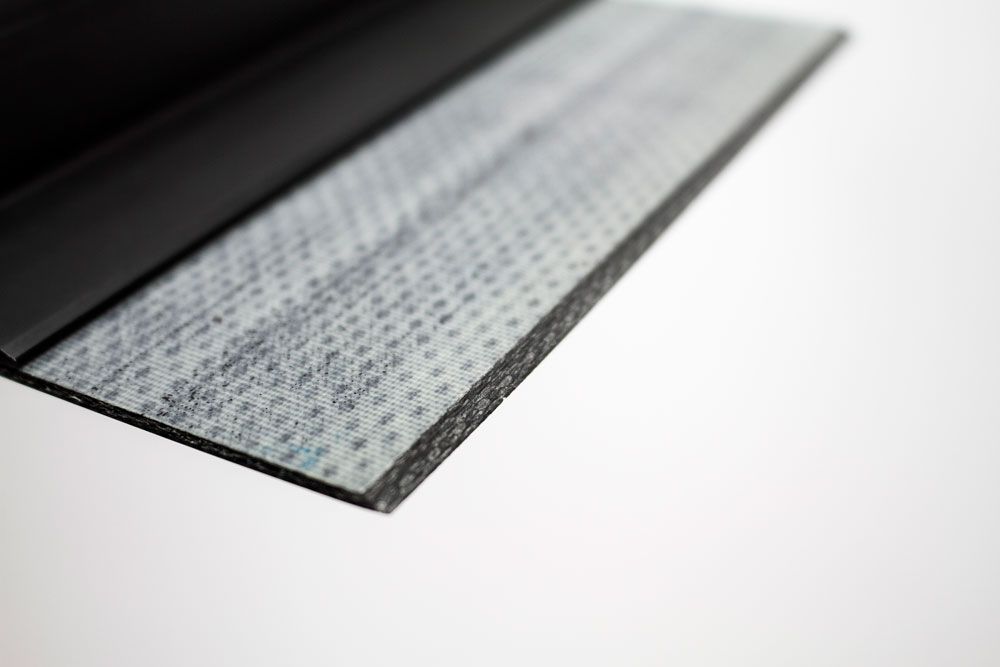

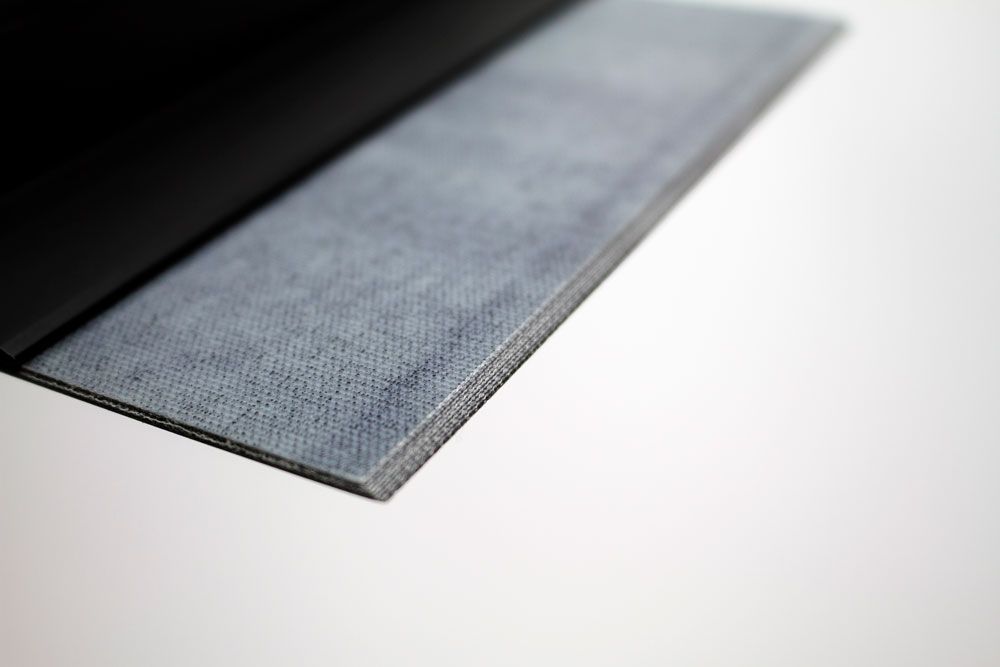

Nanotechnology-enhanced Doctor Blades

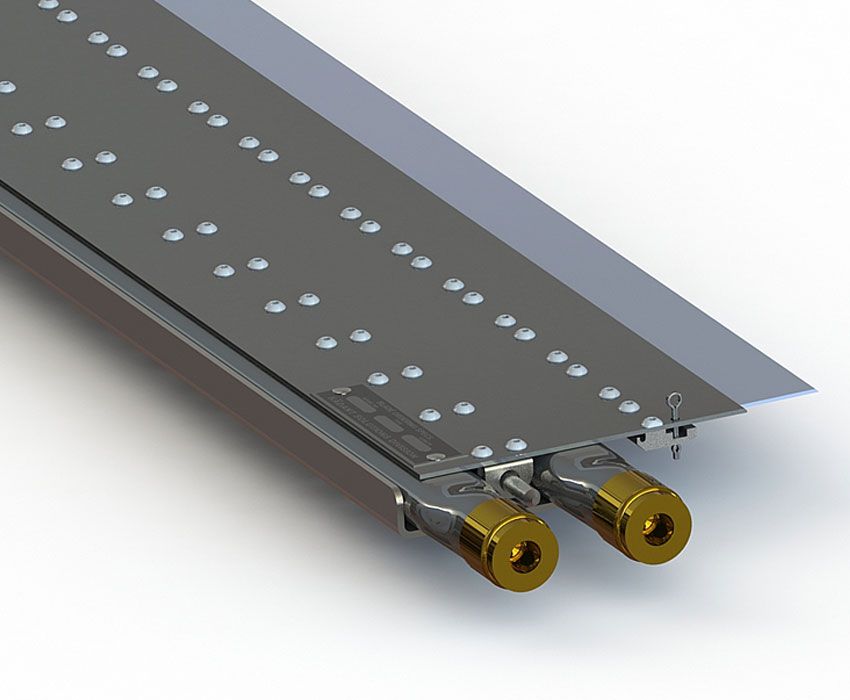

A doctor blade will only effectively clean a roll’s surface if its leading edge remains strong enough. The nanotechnology-enhanced resin matrix is engineered to increase the longevity of the blade and its leading edge. Kadant Research & Development experts have engineered nanotechnology-enhanced doctor blades for rolls where the removal of contaminants is particularly challenging and extended blade life is required. Longer life translates directly to fewer blade changes and lower operating costs while maintaining the cleaning function necessary for machine efficiency.

Patented Nanotechnology-Enhanced Doctor Blades

nForce™ Doctor Blade

- Best for cleaning heavily contaminated cylinders for improved heat energy transfer

- Efficiently handles more challenging positions

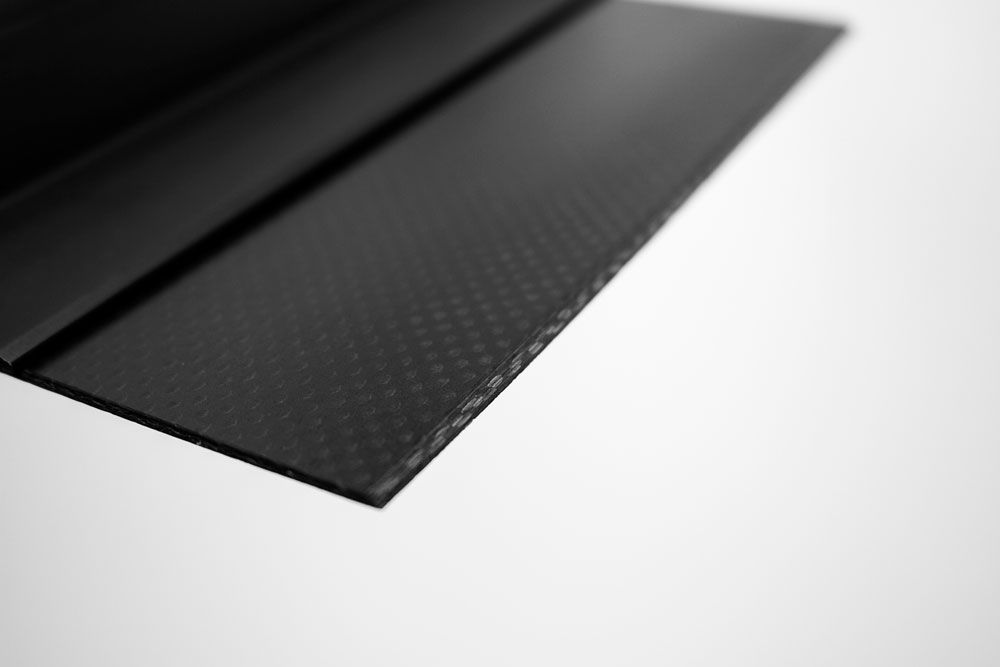

nPak™ C+ Doctor Blade

- Known as the nDure™ doctor blade outside of the U.S.

- Ideal for arduous hard-wearing positions and tough press applications

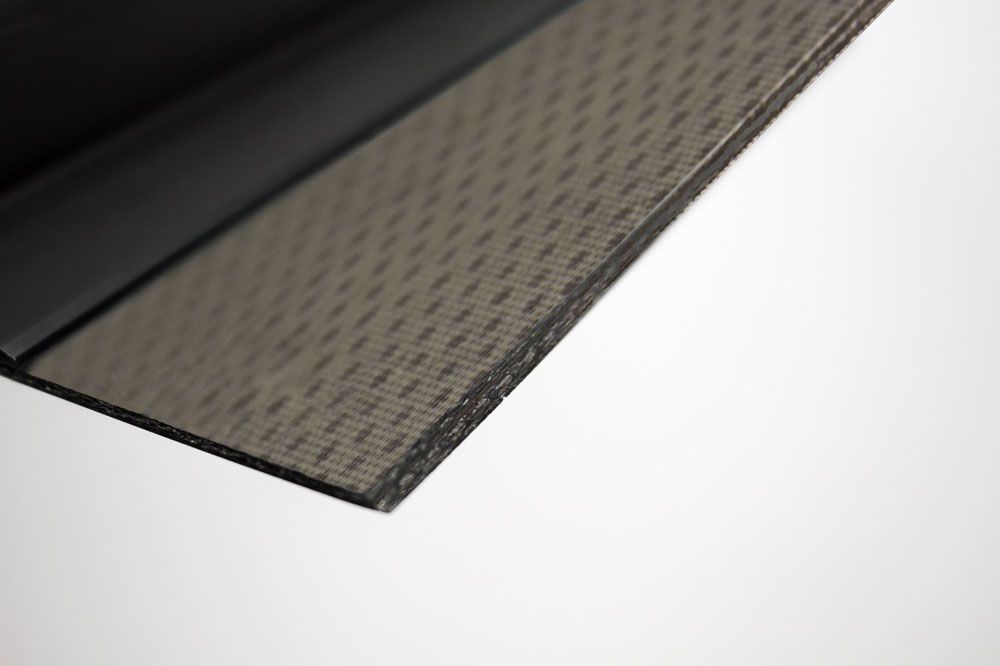

nPak™ CR Doctor Blade

- Known as the nSlip™ doctor blade outside of the U.S.

- Longer blade life due to improved wear resistance

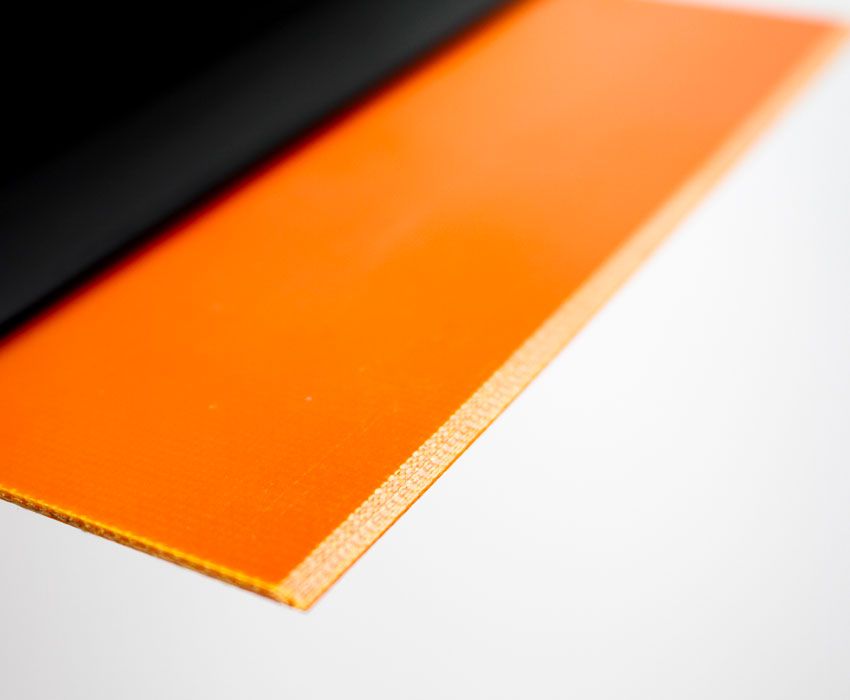

nPak™ GR Doctor Blade

- Known as the nRepel™ doctor blade outside of the U.S.

- Able to clean problematic stickies build up

Features

-

Enhanced resin performance

-

Proprietary capabilities to enable outstanding cleaning and wear life performance

-

Kadant’s latest patented technology to reduce ‘stickies’ accumulation on the doctor blade

Benefits

-

Improved wear life

-

Reduced operation costs

-

Fewer blade changes

FAQ

Kadant’s patented nanotechnology-enhanced doctor blades have proven more successful in solving many of the problems experienced by paper, board, and tissue machines than standard doctor blades. i.e., sheet break, take off issue, shedding position, roll cleaning and ‘stickies’ accumulation.

Very often there is an underlining problem on the machine, which your local Kadant expert will be able to identify and offer the most appropriate solution.

Yes, nanotechnology-enhanced doctor blades solve machine operating issues but can also serve as a method of on-going machine improvement and development.