Industries

We develop, manufacture, and market a wide range of doctoring, cleaning, and filtration systems and related consumables used in process industries worldwide including roofing shingles, food processing, engineered wood, fiberglass mat processing, lithium-ion battery processing, metals processing, nonwovens, pulp & paper, synthetic fibers, and tissue.

Roofing Shingles

Kadant products are used in the manufacturing processes of finished roll roofing and roofing shingle products. Kadant’s latest technologies in roll cleaning systems increase process efficiency, reduce energy costs, and enhance productivity. Roll cleaner assemblies prevent debris buildup on production rolls during production, ensuring smooth operation and reducing downtime.

Engineered Wood

Kadant products are transforming engineered wood manufacturing through advancements in caul screen and press fabric cleaning and wastewater recovery. New technologies in cleaning and filtration are pivotal in streamlining processes and enhancing safety and efficiency. Integrating these systems can significantly reduce energy costs and further their commitment to sustainability, redefining operational excellence.

Fiberglass Mat Processing

Kadant products play a pivotal role in the fiberglass mat production industry, particularly in wire belt cleaning and roll cleaner assemblies. New technologies in cleaning systems align with our dedication to innovation, enhancing process efficiency and safety. These advancements also reduce energy costs and support companies in achieving greater sustainability in their operations.

Food Processing

Kadant products are used in roll, belt, wire, and conveyor cleaning, drum drying, and flaking applications in food processing and tobacco manufacturing. New technologies in filtration and roll and belt cleaning systems increase process efficiency and safety, reduce energy costs, and help companies to be more sustainable in their operations.

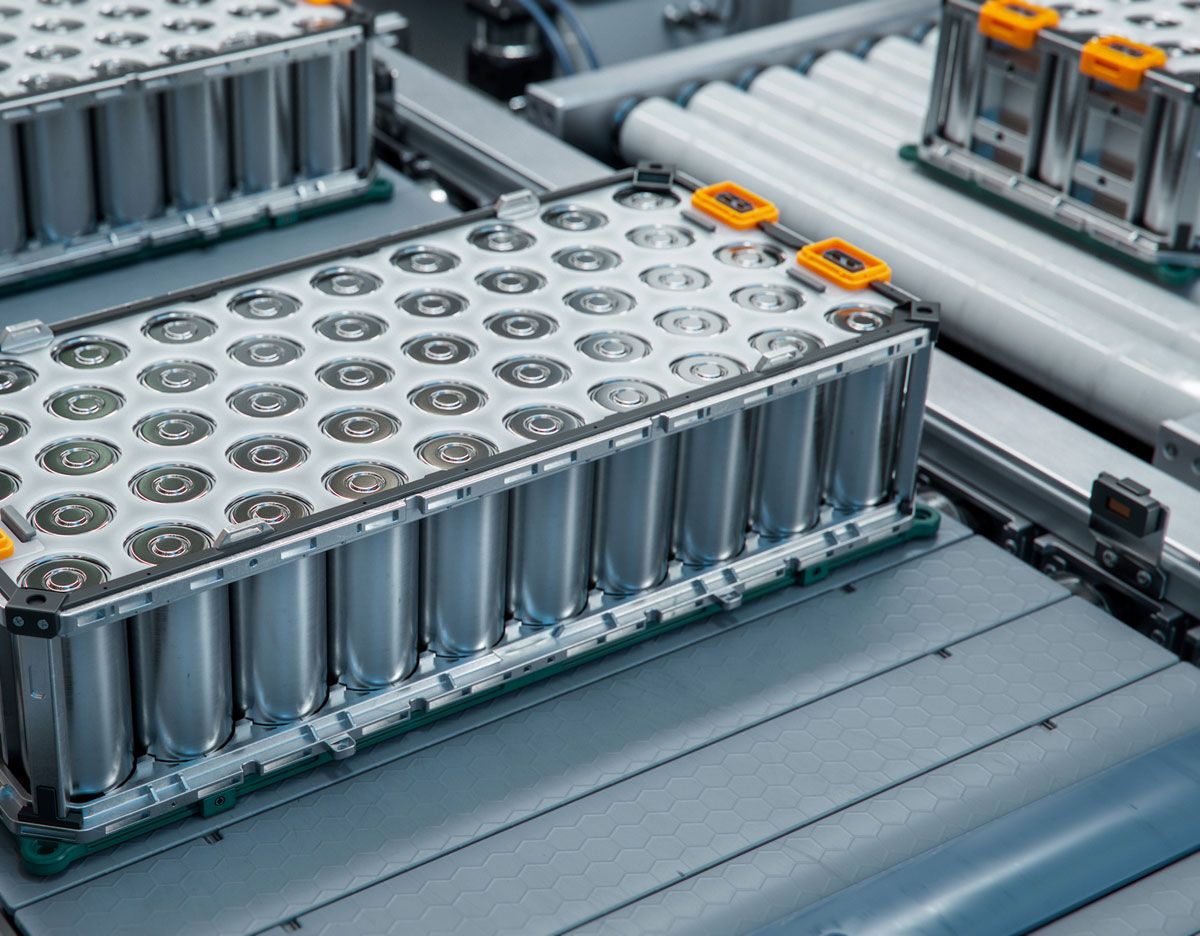

Lithium- Ion Battery Processing

Kadant serves the lithium-ion battery manufacturing industry by enhancing uptime and productivity through our advanced roll cleaning solutions. Specializing in effectively removing debris from calender rolls, which is crucial for ensuring the integrity of the anode and cathode layers. By eliminating potential defects and reducing the risk of roll damage, we optimize production outputs, minimize material wastage, and create a safer environment for operators.

Metals Processing

Kadant products are used in various metal industry applications, including rolling mills, galvanizing, coating, and painting. New technologies in new roll cleaning systems increases efficiency, reduces waste, enhances quality, and promotes sustainability.

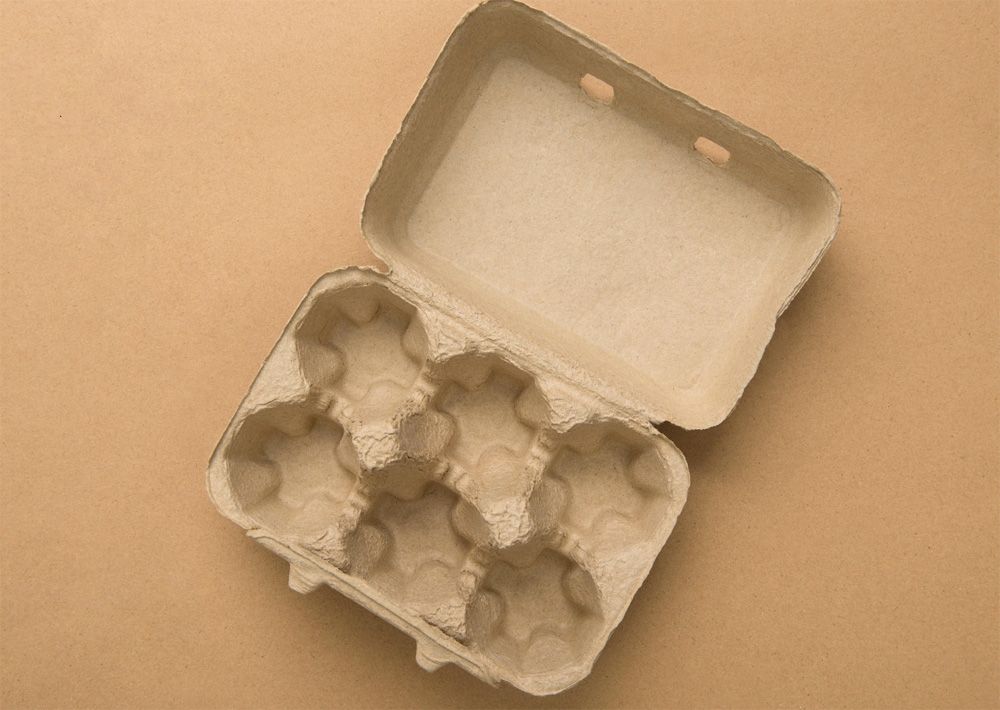

Molded Pulp

Kadant products improve molded pulp manufacturing by offering advanced filtration and resource recovery solutions. This technology filters and reclaims fibers from the process water, further optimizing production efficiency, and supporting sustainability goals. Implementing filtration systems in molded pulp manufacturing can lower costs, improve performance, and establish higher environmental standards across the industry.

Nonwovens

Pulp & Paper

- Doctor & Roll Cleaning Blade Holders

- Doctor & Roll Cleaning Blades

- Double Doctoring Systems

- Electro-Mechanical Oscillators

- Fabric Brush Assemblies

- Filter Media

- Gravity Strainers

- High-Resolution Forming System

- Inline Pressure Filters

- M-clean System

- Mist Elimination Systems

- Multiple-Barrel Pressure Filter

- Nanotechnology-Enhanced Doctor Blades

- Press Section Felt Cleaning Assembly

- Pump Skids

- Varimatic Oscillator

- Split Doctor Bearing

- Spray Nozzles

- Stationary & Oscillating Showers

- Trim Squirt Technology

- Water Resource Recovery Strainers

Synthetic Fibers

Kadant products are used in the treatment, fiber drawing and stretching stages, and finishing applications of synthetic fiber manufacturing processes, including polyester fiber and carbon fiber. New technologies in roll cleaning and filtration systems eliminate fiber breaks and wraps, increase process efficiency, reduce energy costs, and help companies be more sustainable in their operations.

Tissue

- Ceramic Tip Creping Blades

- Doctor & Roll Cleaning Blades

- Doctor & Roll Cleaning Blade Holders

- Electro-Mechanical Oscillators

- Fabric Brush Assemblies

- Filter Media

- Gravity Strainers

- Inline Pressure Filters

- M-clean System

- Mist Elimination Systems

- Multiple-Barrel Pressure Filter

- Press Section Felt Cleaning Assembly

- Pump Skids

- Spray Nozzles

- Stationary & Oscillating Showers

- Trim Squirt Technology

- Water Resource Recovery