Best Practices for Tissue Mill Whitewater Reuse

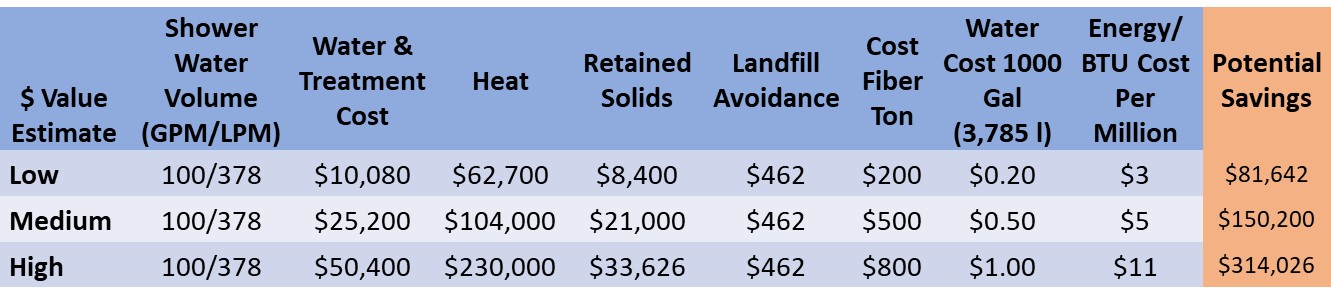

Tissue mills worldwide are striving to improve profitability. A water system optimization project can result in significant savings. Approximately $80,000 to $300,000 can be saved for every 100 gpm of fresh water that is reduced from the mill intake. Potential savings values are shown in the table below.

Measure the Mill Input and Output Vales at the Start of the Project

One key factor to keep in mind when beginning a water reduction project is that any action must change the volume of water going into and out of the mill. Water systems can be very complex. Redirecting water to various locations in the process will not have a positive economic benefit unless the changes impact the input (fresh water) and output water flows (water to the sewer or waste treatment). After a water reduction project, if the mill inlet fresh water flow has not decreased, the project will probably not be considered a success.

Where to Look for Water Savings

Review each tissue machine shower to optimize water use. Nozzle orifice sizes could be oversized causing a shower to consume more water than required. A paper machine shower audit could help determine if too much water is being used. As an example, in a recent nozzle survey, it was determined the shower water being used on a tissue machine could be reduced from 1,900 to 1,300 gpm by changing the spray nozzles to the best practice standard.

Replace worn shower nozzles. A shower with forty-nine 0.040” shower nozzles operating at 200 psi will use about 29,102 gallons of water per day when new. When worn to 0.042”, the volume can increase to more than 32,000 gallons of water per day wasting about 1,000,000 gallons of water each year.

Balance the process to eliminate overflowing tanks. Many mills have whitewater systems that can go out of balance resulting in a loss of water and fiber to the sewer. If this problem exists, a review of the entire water system balance may be necessary.

Reuse vacuum pump seal water. If fresh water is being reused as vacuum pump seal water, the installation of a recirculating vacuum pump seal water system could save 100 to 2,000 gpm of water per day.

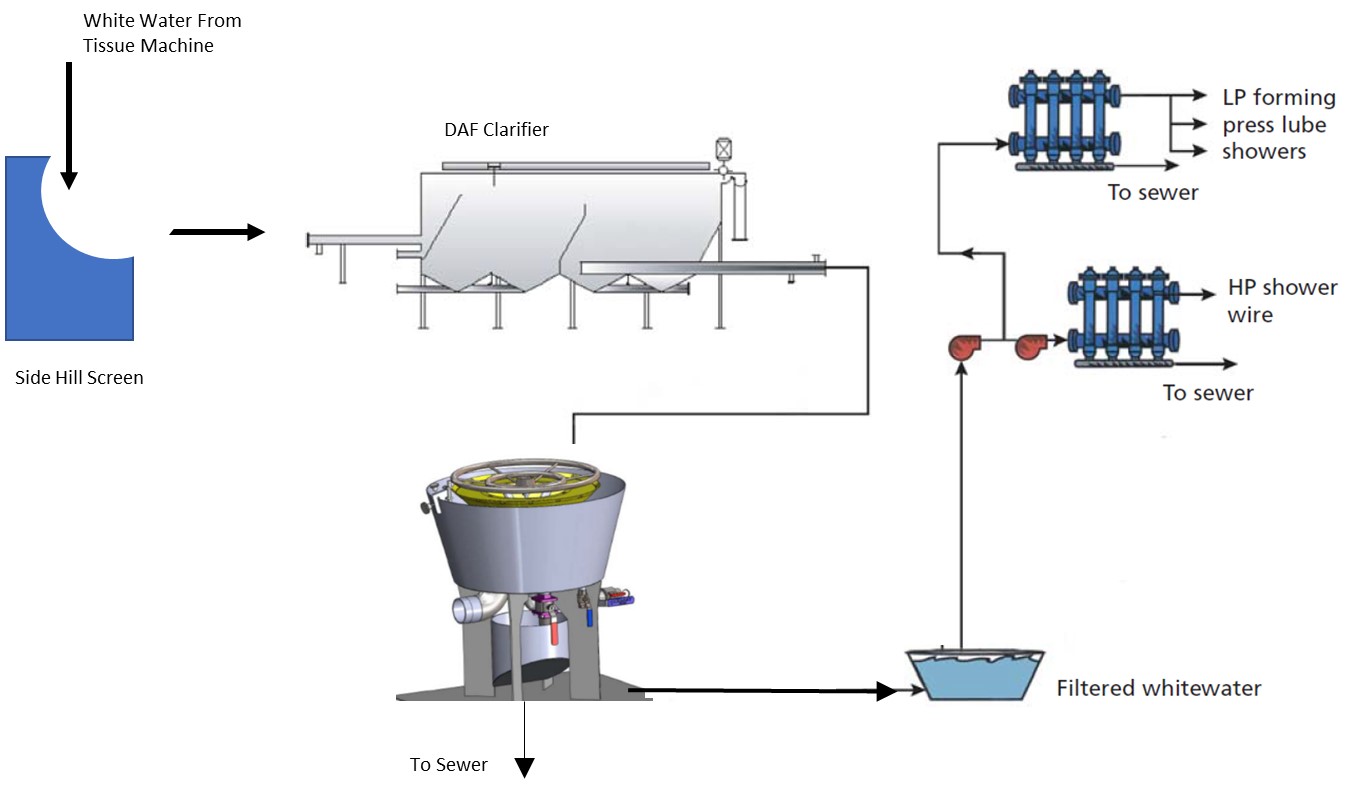

Replace fresh water with white water from the saveall or DAF clarifier. Most paper machine showers (exceptions are high-pressure felt cleaning and trim squirt showers) can utilize clarified white water if it is properly conditioned before use. A typical white-water filtration system is shown below.

A proper system filters clarified white water (from DAF or saveall) twice before it reaches the machine shower. The first filtration stage uses a product like the Rotoflex™ resource recovery strainer to remove tons/day of fiber. The filtrate from stage one flows to a tank and is pumped to a polishing filter like the ErGo™ filtration system that will remove any agglomerated fiber and contaminants that may potentially plug shower nozzles.

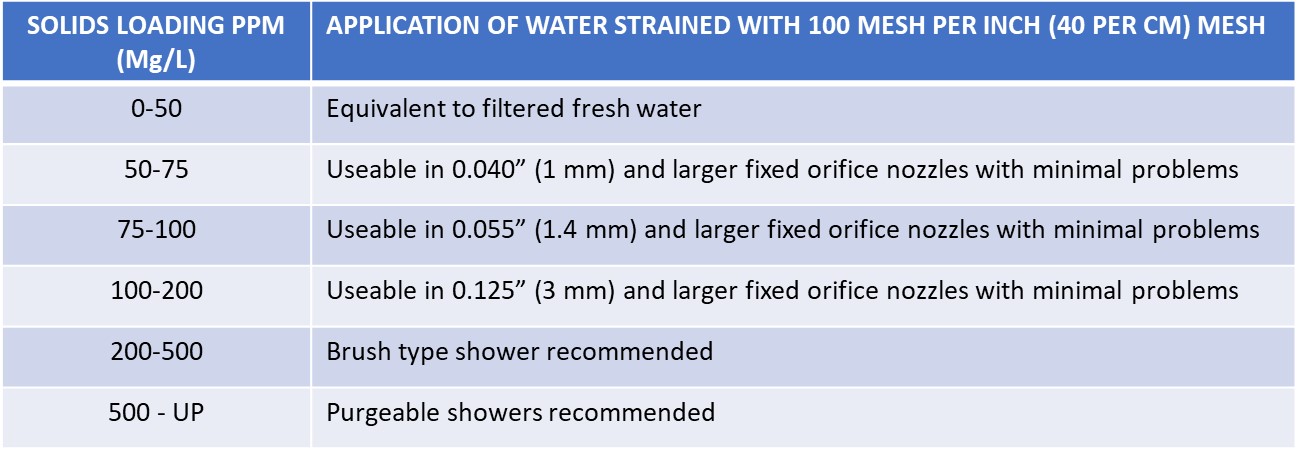

When replacing fresh shower water with white water, the last issue to consider is the type of shower required. Fixed orifice showers, brush showers, and purgeable showers are all commonly used in white water applications. The best practice shower selection is based on the orifice size and the quality of the white water after the filtration system. Refer to the chart below as a guide for selecting the correct shower for your mill application.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.