VeriKleen™ Roll Cleaner Assembly

The VeriKleen roll cleaner assembly is used in process industries where roll and belt cleaning applications require a design that is both compact and provides excellent cleaning results to improve uptime and reduce maintenance costs.

Features

-

HACCP International food safe certified in the U.K. and U.S.

-

Lightweight metal alloy construction

-

Compact design fits into tight locations

-

Suitable for high temperature environment

-

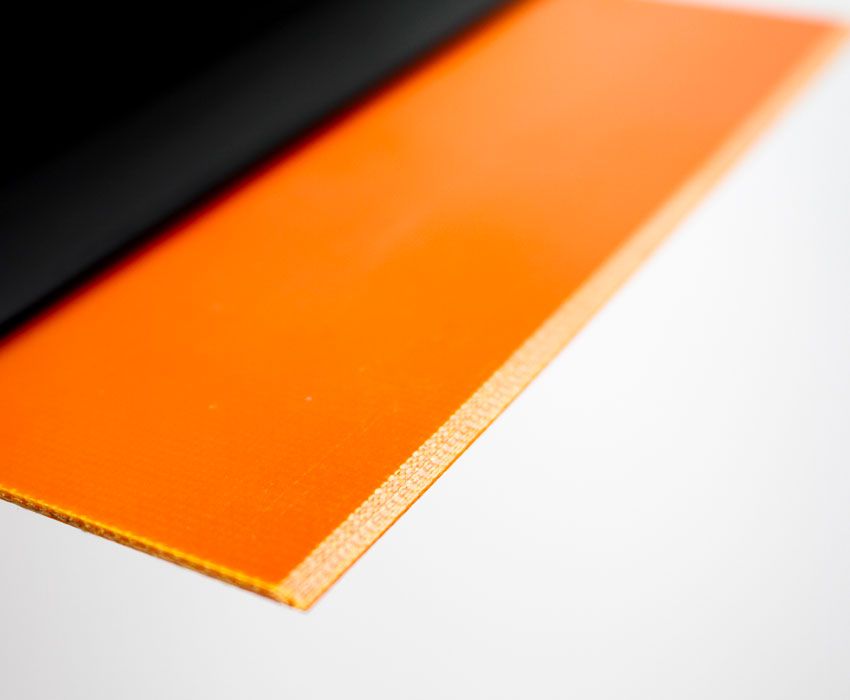

Large selection of blade materials

Benefits

-

Effective cleaning at minimal blade pressure

-

Quick blade changes only take seconds

-

Low maintenance

-

Suitable for high-temperature environments

Stories

FAQ

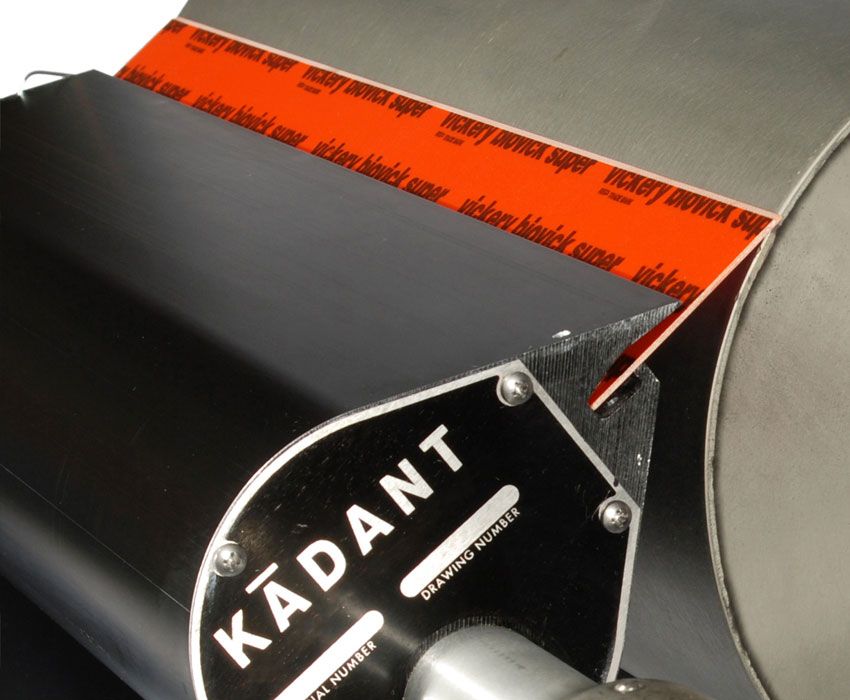

The VeriKleen roll cleaner assembly is loaded by air cylinders or a manual loading device and is more suitable for harsher environments where contaminants could limit the VeriLite roll cleaner assembly’s effectiveness.

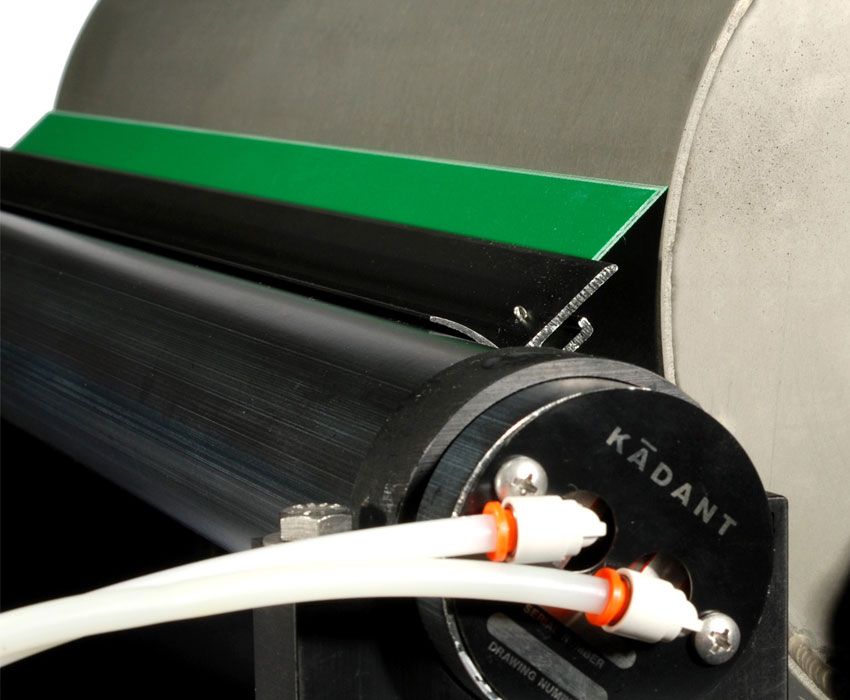

The VeriLite is more compact than the VeriKleen. The VeriLite utilizes custom air tubes to pivot the VeriLite top plate with blade to and from the roll cleaning surface. The VeriLite structure is fixed in position while the blade or cleaning pad is engaged to the cleaning surface. The VeriKleen structure has an integrated blade cavity and the VeriKleen body itself is rotated to and from the roll cleaning surface by means of loading mechanisms such as an air cylinder or pressure rig assembly.

The VeriKleen roll cleaner assembly is designed to incorporate a free-floating roll cleaning blade that can easily be slid out of the assembly in a matter of seconds. No tools are required to remove the roll cleaning blade, and the special hardware on the blade or pad is designed to easily slide in and out of the holder.

Yes, using the Varimatic™ 500 oscillator. Oscillation provides a secondary cutting action and can make roll cleaning more effective along with minimizing blade wear, vibration and roll damage.