Proven ROI at a South U.S. Tissue Mill Using the RotoFlex™ Resource Recovery Strainer

The RotoFlex resource recovery strainer is used to reclaim white water, heat, chemicals, and fiber effectively and efficiently from various process industry applications. Learn more about the proven return on investment from this case study about a United States tissue mill.

Challenge

Challenge

A Southern U.S. tissue mill wanted to use wire pit water in the showers but could not do so because fiber would plug the hydra sieves downstream of the Krofta (DAF clarifier). River process water (RPW) was the only other shower water available. Because the mill was unable to reuse the clarified white water, this went to sewer along with the fiber. The use of cooler RPW water in the machine showers was suspected to reduce the efficiency of the tissue machine.

Solution

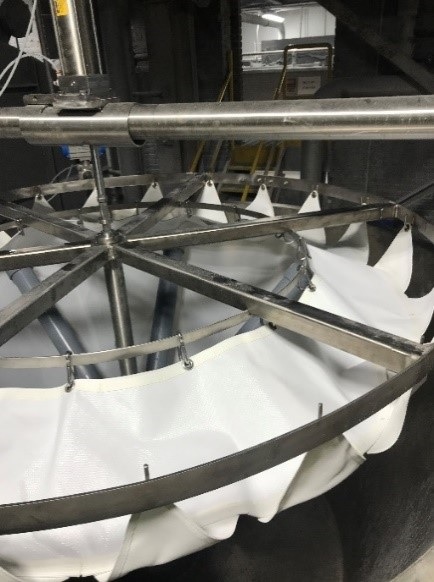

Kadant Solutions recommended and installed a RotoFlex resource recovery strainer (1200) to filter the water, capture valuable fiber, and reuse the river process water.

Results

The main savings is from the reuse of about 500 gpm of white water in place of RPW water in the showers. The mill’s projected water cost is about $0.25 per 1,000 gallons. The following is a summary of annual savings:

- Fiber: $97,020

- Water: $62,806

- Improved machine operations: $43,750

- Total projected annual savings: $203,576

- Return on investment projected at 19.75 months

The water costs in the above ROI calculation are for U.S. conditions only.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.