Cleaning

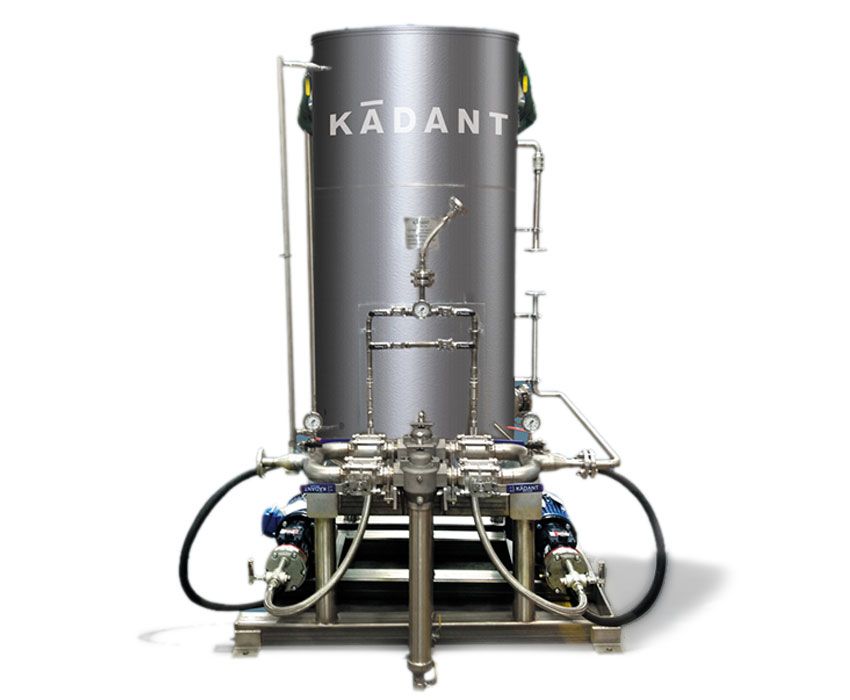

Cleaning and conditioning products, such as the M-clean™ system, spray nozzles, stationary and oscillating showers, electro-mechanical shower oscillators, fabric brush assemblies, and trim squirt systems, are designed to remove contaminants from fabrics, felts, belts, wires, and rolls in process industries.

Common applications for cleaning and conditioning systems include roll and doctor lubrication, conveyor and belt cleaning, product knock-off, cylinder cleaning, chemical cleaning, high-pressure belt press fabric and cylinder cleaning, drilled suction roll cleaning, and sludge press cleaning.

FAQ

Spray nozzles are a precision engineered component that plug and wear over time during normal operation or cleaning. However, proper filtration and water quality can protect the health of the spray nozzle. In addition to filtration and water quality, it’s important to choose the proper orifice size for the application.

Yes. There is a full spray nozzle catalog available under the knowledge center.

Kadant recommends changing all bearings, seals, and wear components during oscillating shower maintenance.

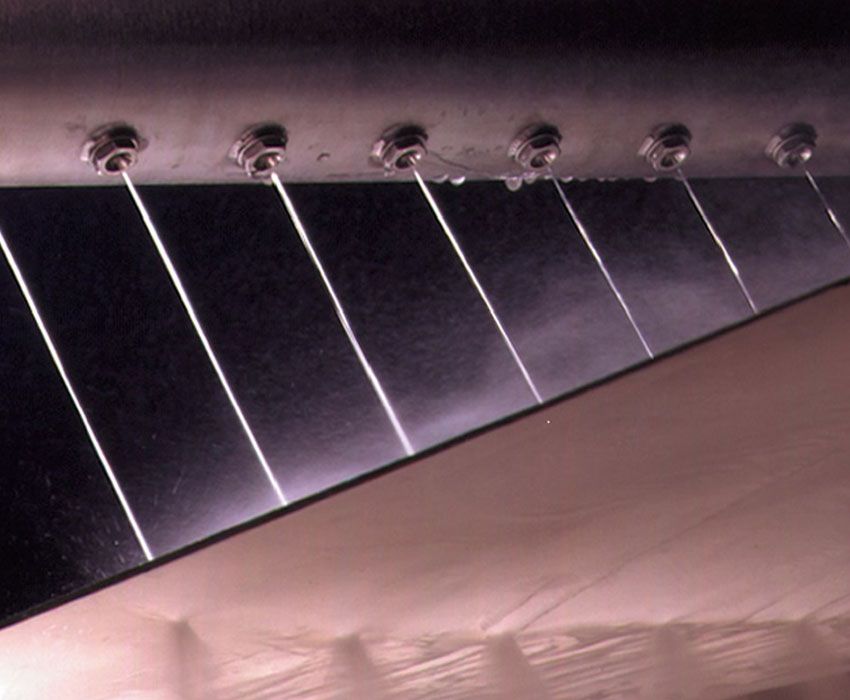

A high performing trim squirt nozzle provides clean and precise sheet trimming and offers jet quality (laminar length), wear resistance, proper geometry, single or double jet availability, and nozzle design to move drops away from jet to avoid jet interruptions.