Doctor & Roll Cleaning Blades

With thousands of installations around the globe, our doctoring and roll cleaning technologies offer high-performance cleaning and water removal in a variety of roll cleaning and scraping applications.

- Construction Roofing Materials

- Corrugating

- Food Processing

- Lithium-ion Battery Processing

- Metals Processing

- Nonwovens

- Pulp & Paper

- Textiles & Fibers

- Tissue

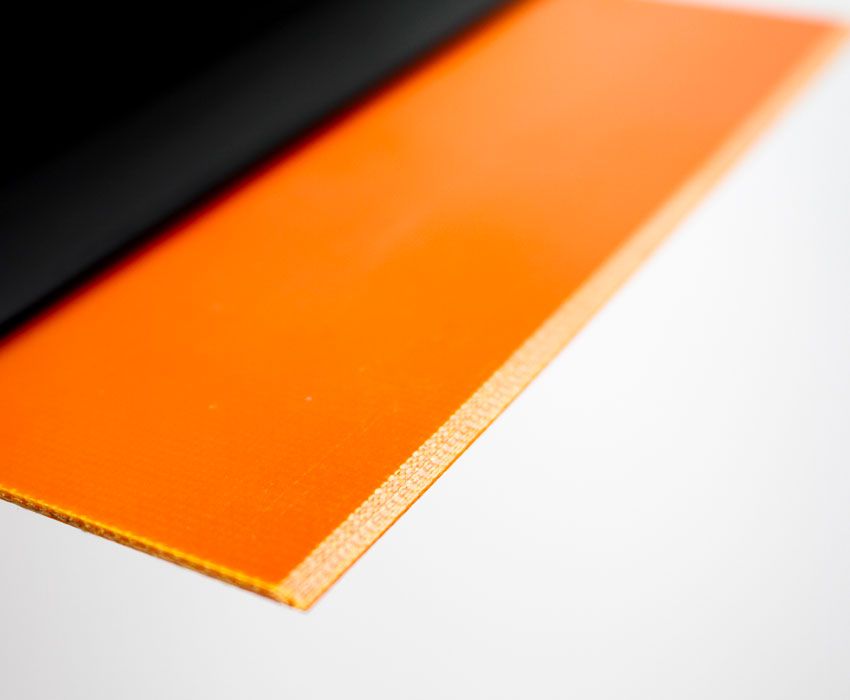

AbrasiTek™ doctor blade

A glass epoxy doctor blade with standard abrasives for the conditioning of dryer surfaces.

AbrasiTek™ roll cleaning blade

A glass epoxy roll cleaning blade with standard abrasives for the conditioning of dryer surfaces.

AbrasiTek™ 100 doctor blade

A glass epoxy doctor blade with coarse abrasives recommended for conditioning of dryer surfaces.

ArmorTek™ doctor blade

A metal doctor blade with proprietary coating that provides enhanced performance with low friction.

Biovick™ Super doctor blade

A glass epoxy doctor blade used for extra life blade for tough high temperature cleaning applications.

Bronzeflex™ doctor blade

A high carbon bronze alloy, corrosion resistant roll cleaning blade recommended for steel or cast iron rolls.

Bronzeflex™ roll cleaning blade

A high carbon bronze alloy, corrosion resistant roll cleaning blade recommended for steel or cast iron rolls.

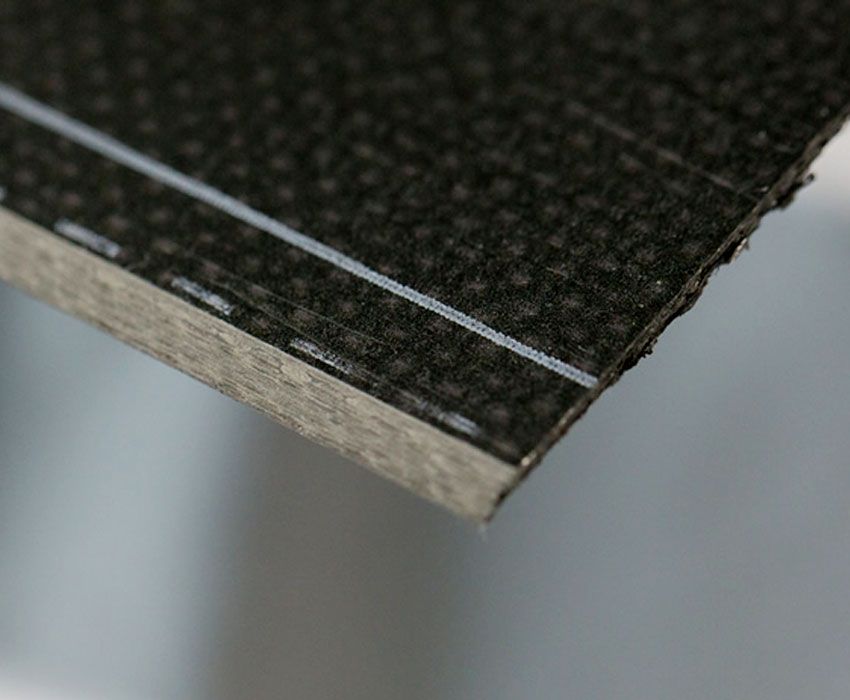

CarboTek™ 500 doctor blade

A long-life carbon fiber doctor blade for sheet shedding positions where high temperature resistance is required.

CarboTek™ 500 roll cleaning blade

A long-life carbon fiber roll cleanings blade for sheet shedding positions where high temperature resistance is required.

Carbovick™ doctor blade

A multi-axial carbon fiber, glass fiber, and epoxy resin doctor blade for high temperature applications.

CeraEdge™ L creping blade

A ceramic-tip coated creping blade design for tissue applications that require extended blade life.

CeraEdge™ S creping blade

A ceramic-tip coated creping blade design for tissue applications that require high softness.

CleanTek™ S doctor blade

A glass epoxy, extra life doctor blade for touch cleaning applications.

Dritek™ Bronze doctor blade

A 100% steel doctor blade with a ceramic coating that minimizes sheet wraps and extends blade life.

Dritek™ Bronze roll cleaning blade

A 100% steel roll cleaning blade with a ceramic coating that minimizes sheet wraps and extends blade life.

DriTek™ C doctor blade

Dritek C is 100% unidirectional carbon with high temperature resin with a coating to remove stickies from challenging dryer cans.

DriTek™ Steel doctor blade

A 100% steel doctor blade with ceramic coating that minimizes sheet wraps and extends blade life.

DuroTek™ doctor blade

A doctor blade recommended for applications where a thinner, stiff polymeric blade is needed.

Fiberflex™ doctor blade

A glass epoxy doctor blade for roll cleaning applications.

Graflex™ doctor blade

A glass and carbon epoxy doctor blade for added strength in the MD and for extreme conformability.

Grafgrit™ 200 doctor blade

A carbon and glass fiber roll cleaning blade with 200 grit abrasive in epoxy resin typically used in the secondary position of a center press on a ceramic roll.

Grafgrit™ 400 doctor blade

A carbon and glass fiber roll cleaning blade with 400 grit abrasive in epoxy resin typically used in the secondary position of a center press on a ceramic roll.

Grafgrit™ 400 roll cleaning blade

A carbon and glass fiber roll cleaning blade with 400 grit abrasive in epoxy resin typically used in the secondary position of a center press on a ceramic roll.

Lamflex™ doctor blade

A cotton and phenolic resin laminate doctor blade that is gentle on the roll's surface.

Multitek™ C doctor blade

A long life doctor blade made of glass and proprietary oriented carbon which aids in the removal of stickies and roll contaminants.

PlusTek™ C doctor blade

A fiberglass and carbon doctor blade with epoxy resin laminate for rolls needing increased cleaning capability or extended life.

PolyCarb™ doctor blade

A UMHW and carbon doctor blade designed for non-polyurethane wet end rolls where extended life is required.

PolyFlex™ doctor blade

A roll cleaning blade constructed of UHMW polyethelyene and is gentle on roll covers.

PolyFlex™ roll cleaning blade

HACCP International food safe certified roll cleaning blade constructed of UHMW polyethelyene and is gentle on roll covers.

PolyFlex™ roll cleaning blade

A roll cleaning blade constructed of UHMW polyethelyene and is gentle on roll covers.

PressTek™ Plus doctor blade

A coated stainless steel doctor blade designed for difficult shedding positions that provides long life and surface conditioning properties.

ProClean™ roll cleaning blade

A bi-metal alloy roll cleaning blade with a tough, non-brittle wear resistant alloy with low friction.

ProClean™ doctor blade

A bi-metal alloy doctor blade with a tough, non-brittle wear resistant alloy with low friction.

ProCrepe® Plus creping blade

A tough, non-brittle wear resistance bi-metal alloy creping blade with low friction.

SofTek™ doctor blade

A carbon and plastic fiber doctor blade with epoxy resin for long life with enhanced cleaning.

Stainlessflex™ creping blade

A creping blade constructed of 400 series stainless steel for corrosive applications.

Stainlessflex™ doctor blade

A doctor blade constructed of 400 series stainless steel for corrosive applications.

Stainlessflex™ roll cleaning blade

HACCP International food safe certified roll cleaning blade constructed of 400 series stainless steel for corrosive applications.

SteelFlex™ creping blade

A high carbon steel creping blade for most rolls in non-corrosive environments.

SteelFlex™ doctor blade

A doctor blade for most rolls in non-corrosive environments.

SteelFlex™ roll cleaning blade

HACCP International food safe certified high carbon steel roll cleaning blade for most rolls in non-corrosive environments.

SynTek™ C doctor blade

A 100% carbon doctor blade with enhanced resin for long life and enhanced cleaning.

SynTek™ Plus doctor blade

A glass and carbon doctor blade with enhanced resin best suited for where nominal cleaning with enhanced life is required.

SynTek™ Plus roll cleaning blade

A glass and carbon roll cleaning blade with enhanced resin best suited for applications where nominal cleaning with long life is required.

Ultra™ CTC doctor blade

A carbon fiber doctor blade with carbide sprayed tip that provides long life and wear resistance.

UltraKleen™ X roll cleaning blade

A glass epoxy roll cleaning blade for roll cleaning in high temperature applications.

UltraKleen™ X doctor blade

A glass epoxy doctor blade for roll cleaning in high temperature applications.

X-Tek™ Roll Cleaning Blade

A polymeric and carbon blade designed for high-temperature applications with highly polished roll surfaces.