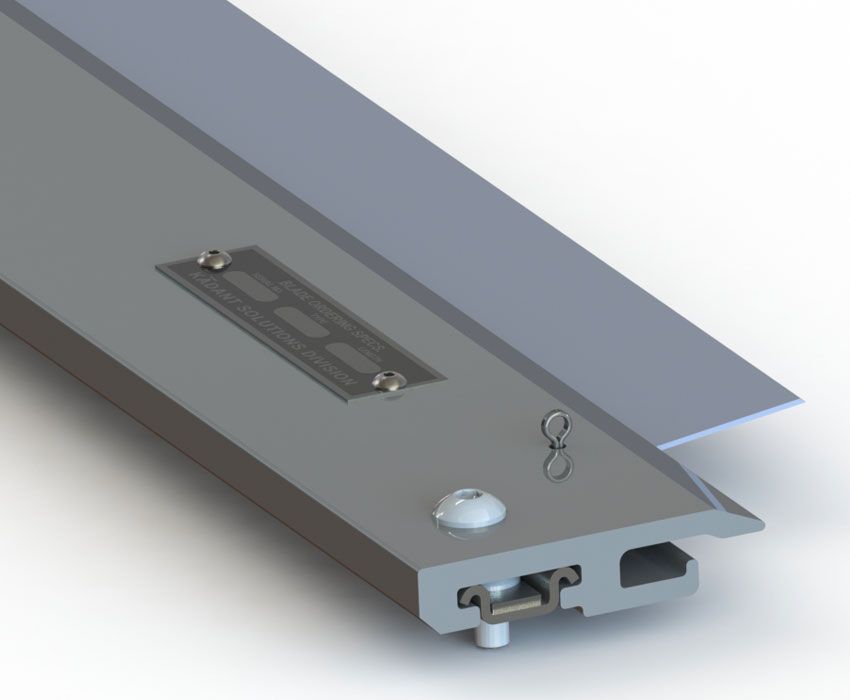

Doctor & Roll Cleaning Blade Holders

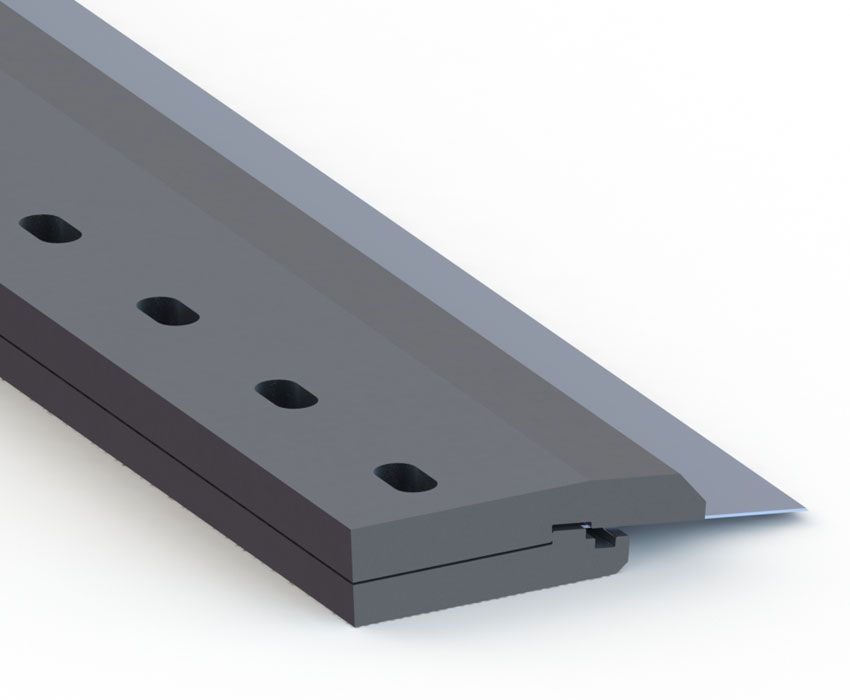

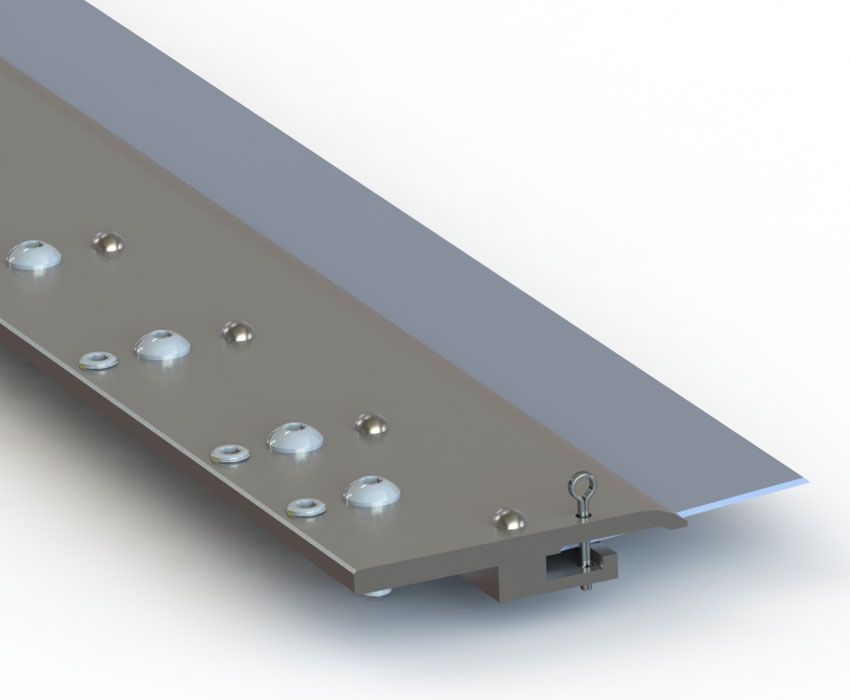

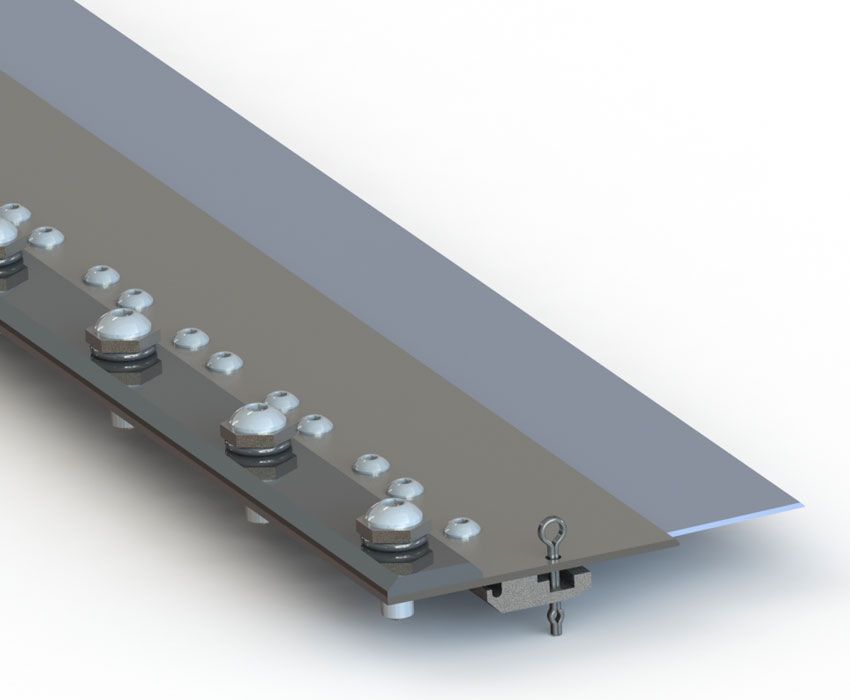

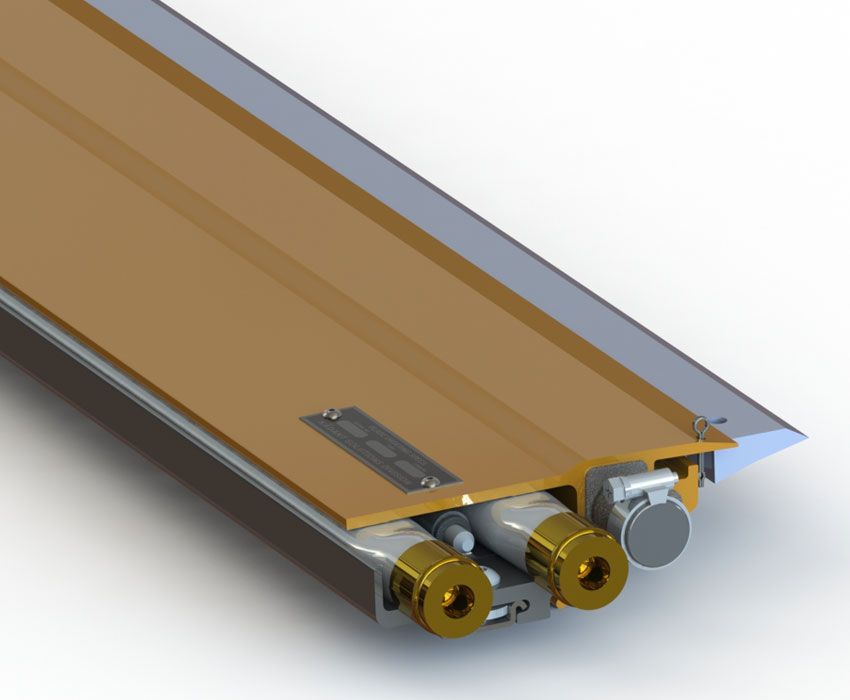

Blade holders position the doctor or roll cleaning blade firmly against the roll, accommodate roll surface irregularities, facilitate rapid blade changes, and, within limits, compensate for thermal expansion.

Proper doctoring or roll cleaning is critical to many industrial processes and goes beyond choosing a doctor or roll cleaning blade.

Blade Holders

AccuClean™

Open fingertip design allows for self-cleaning and eliminates clogging of the blade cavity. Applications include wire rolls, felt rolls, dryers, and calender rolls.

AccuFlake™

Designed specifically for drum flaker applications and the flaking process. This blade holder features quick blade changes, open design for cleanliness, and precise adjustability.

AccuFlake™ PRO

Designed specifically for drum flaker applications and the flaking process. The patent-pending AccuFlake PRO blade holder allows for easy retrofit of existing clamp type OEM flaking doctor blade holders. Provides an instant upgrade to the convenience, efficiency, and overall effectiveness of “floating” doctor blades.

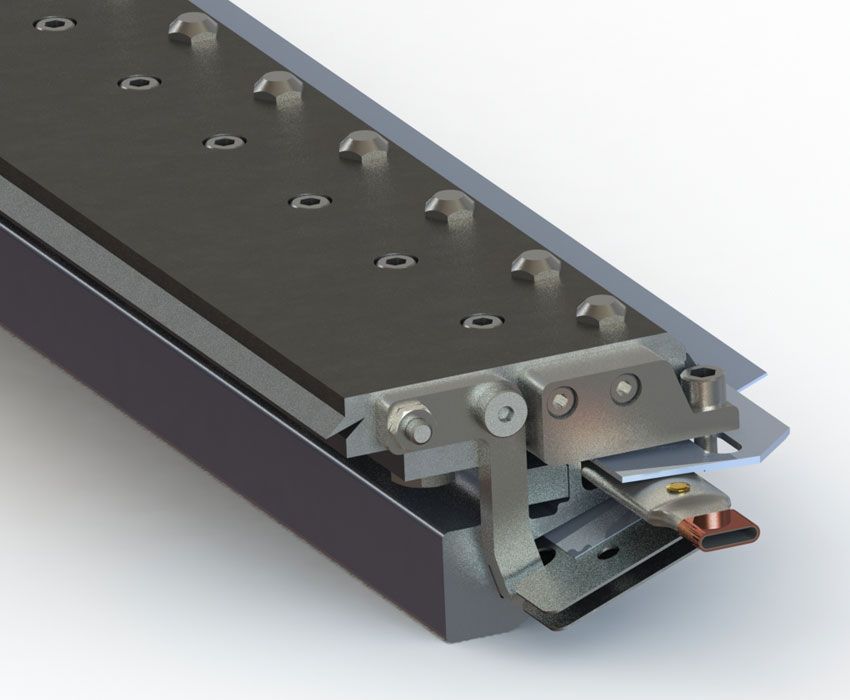

Accumate™

This is the original industry standard all-purpose blade holder. Rugged and highly dependable, it features micro adjusting screws that enable precise blade fit. Applications include wire rolls, felt rolls, dryers, and calender rolls.

AccuTek™

An economical blade holder that is easy to install with minimal maintenance. The cross-machine flexibility makes it self-conforming without the need for micro adjusting screws. Applications include breast roll, wire rolls, felt rolls, dryers, calender rolls, and reel drums.

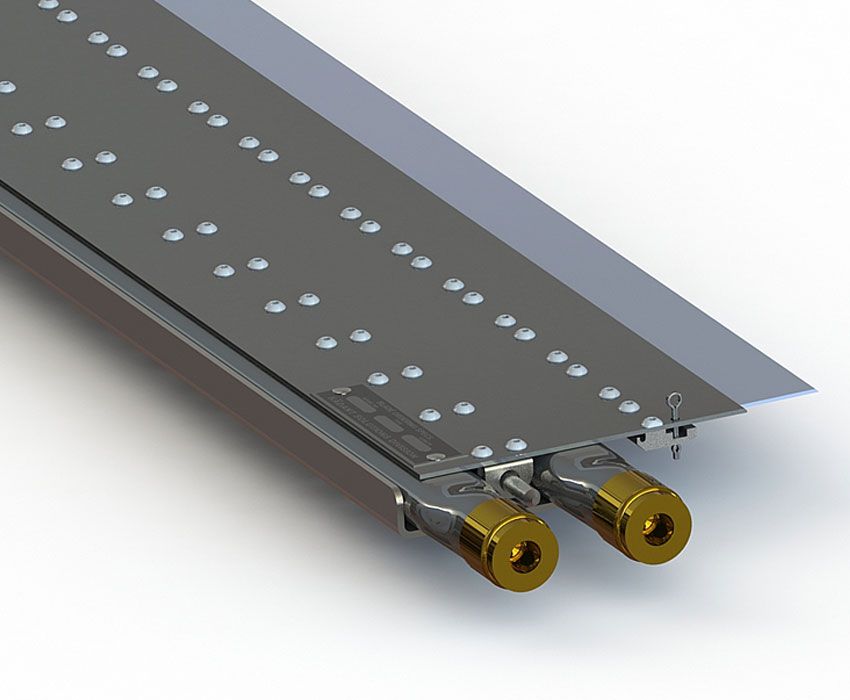

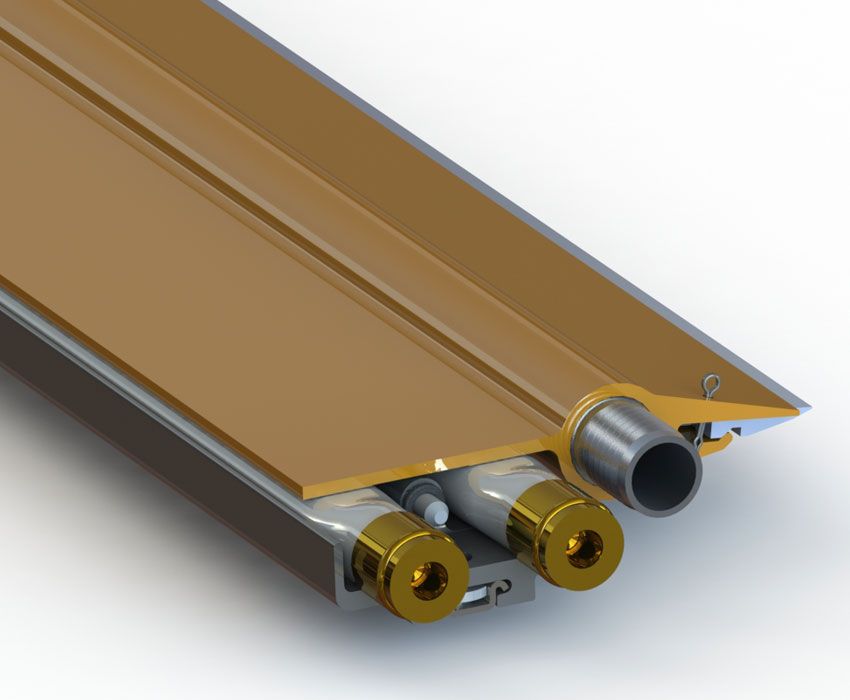

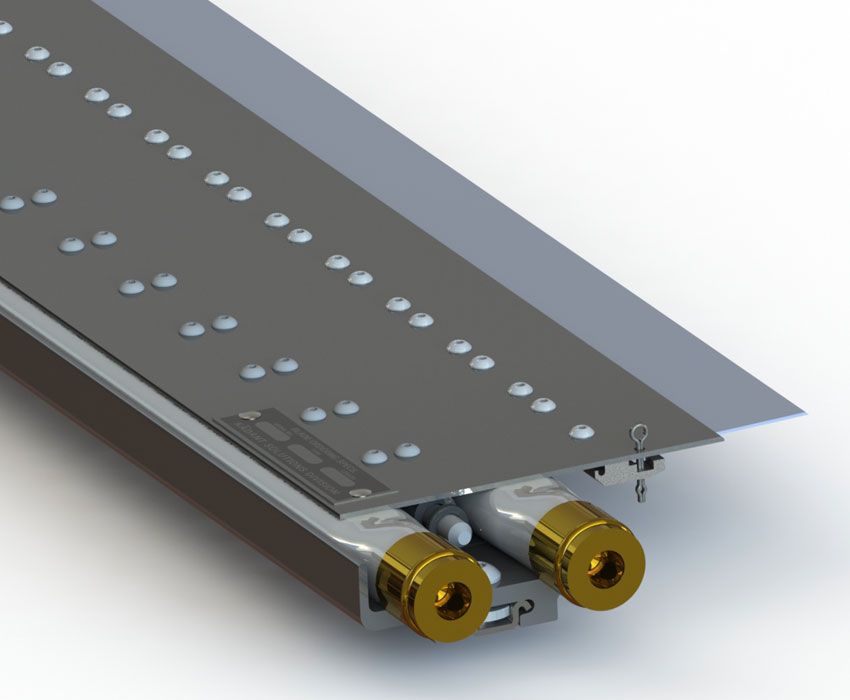

AirSet™ B

Tube loaded blade holder with engineered shape and integrated air cavity to amplify vacuum and enhance dewatering of drilled rolls. Applications include couch rolls, suction and blind drilled press rolls, and suction pressure rolls.

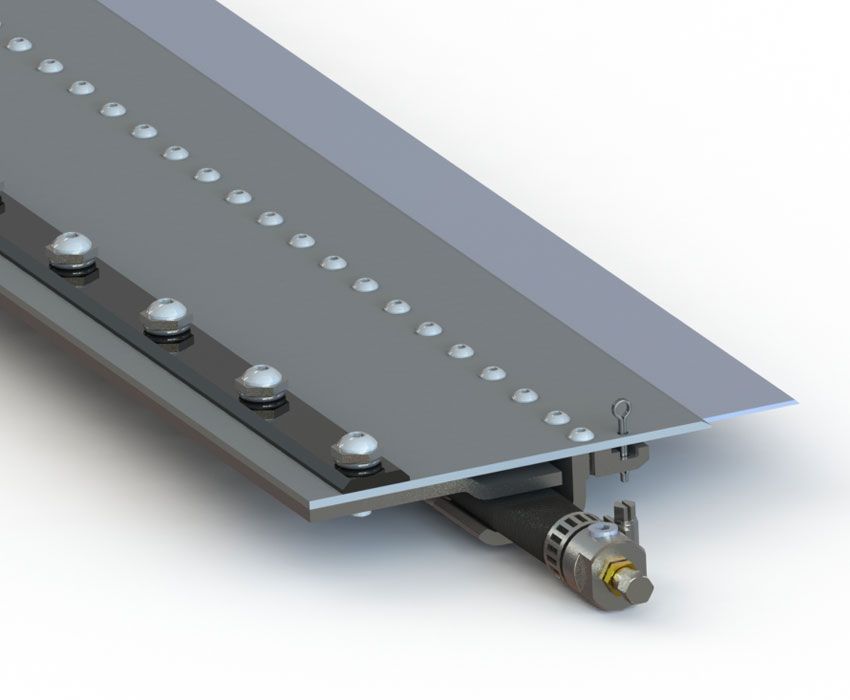

AirSet™ T

Tube loaded blade holder with integrated air cavity that targets air delivery at the blade for cleaning and dewatering grooved press rolls.

Conformatic™ AL

The next generation Conformatic creping blade holder. Precise bi-directional profiling of the Yankee crown without the need for edge fingers. Provides uniform sheet quality, reduced Yankee dryer surface wear, and longer blade life.

Conformatic™ L

Designed for Yankee doctoring systems with loading pressure requirements up to 25 PLI. Features a backup blade and Conformatic tube for uniform pressure. Provides uniform sheet quality, reduced Yankee dryer surface wear, and longer blade life.

Conformatic™ XL

Designed for Yankee doctoring systems with loading pressure requirements up to 80 PLI. Backup blade and Conformatic tube for uniform pressure and open design for hygiene. Provides uniform sheet quality, reduced Yankee dryer surface wear, and longer blade life.

DST-E™

An enhanced, low-profile DST designed for high performance doctoring that provides balanced blade pressure across the roll surface for light duty cleaning applications. Applications include breast rolls, suction couch and press rolls, wire rolls, and felt rolls.

EzKleen™ Roll Polishers

Cleaning pad that safely and effectively removes build-up from the roll surface. Designed for a wide variety of applications and for porous roll surfaces that require specialized surface cleaning and conditioning.

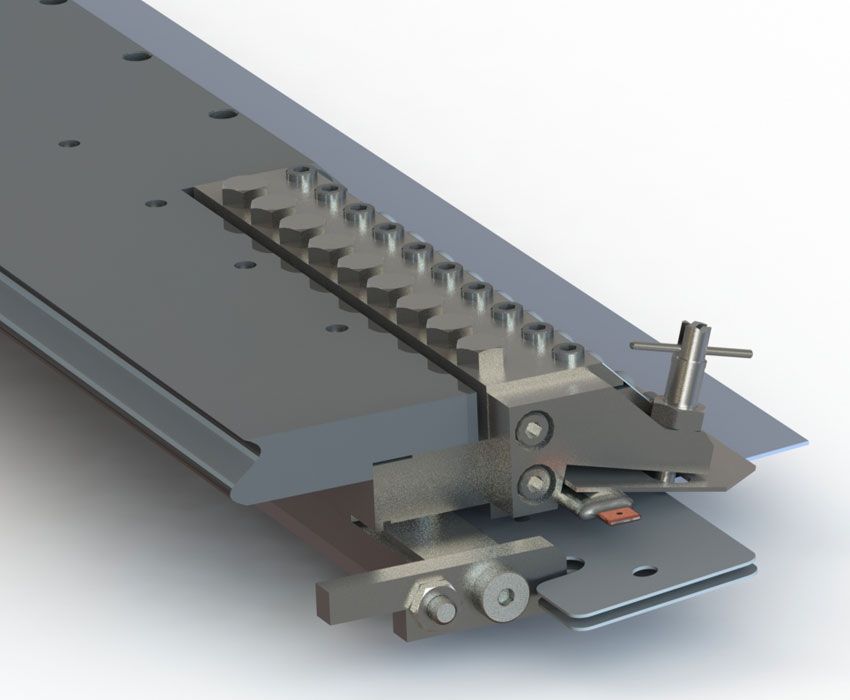

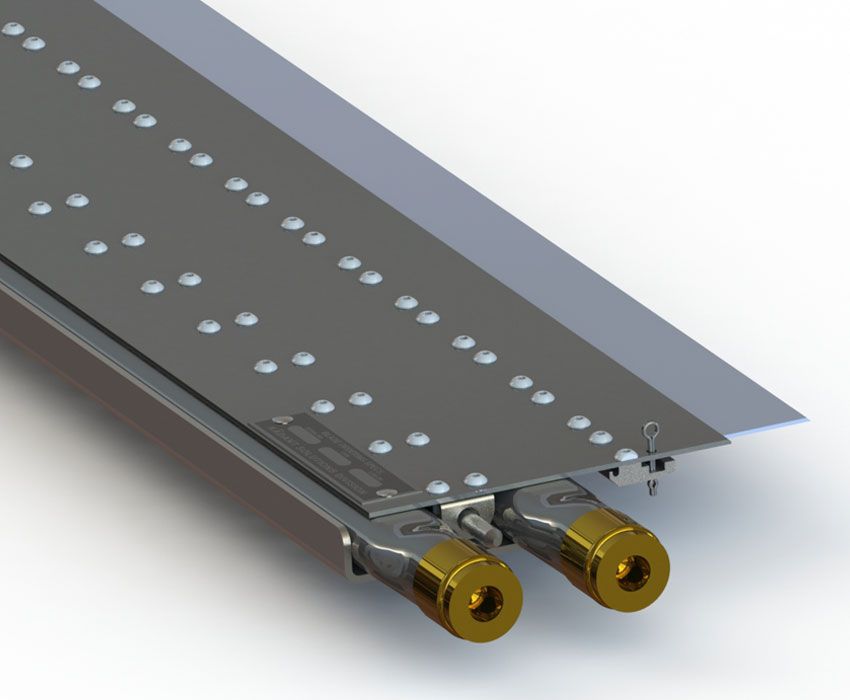

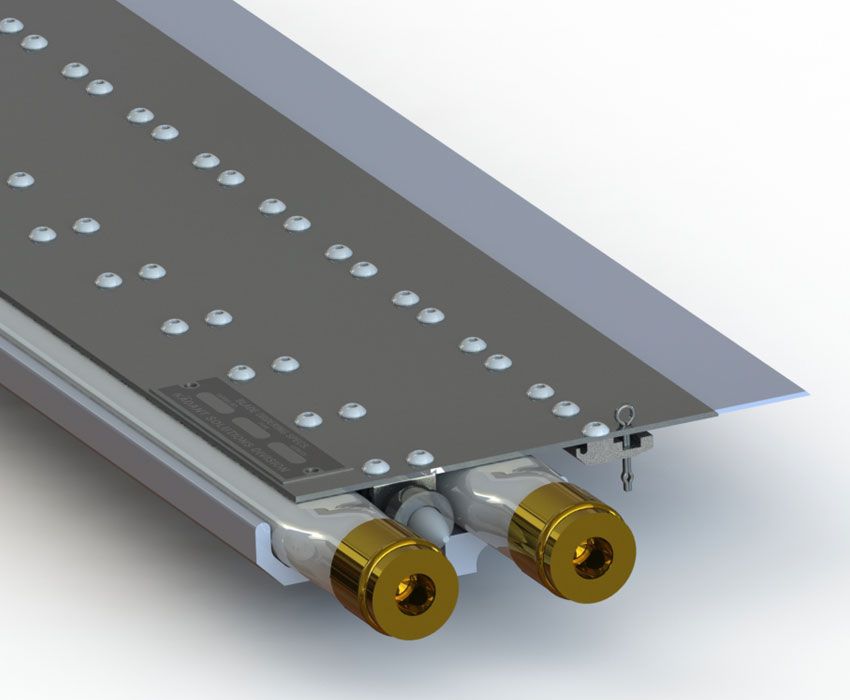

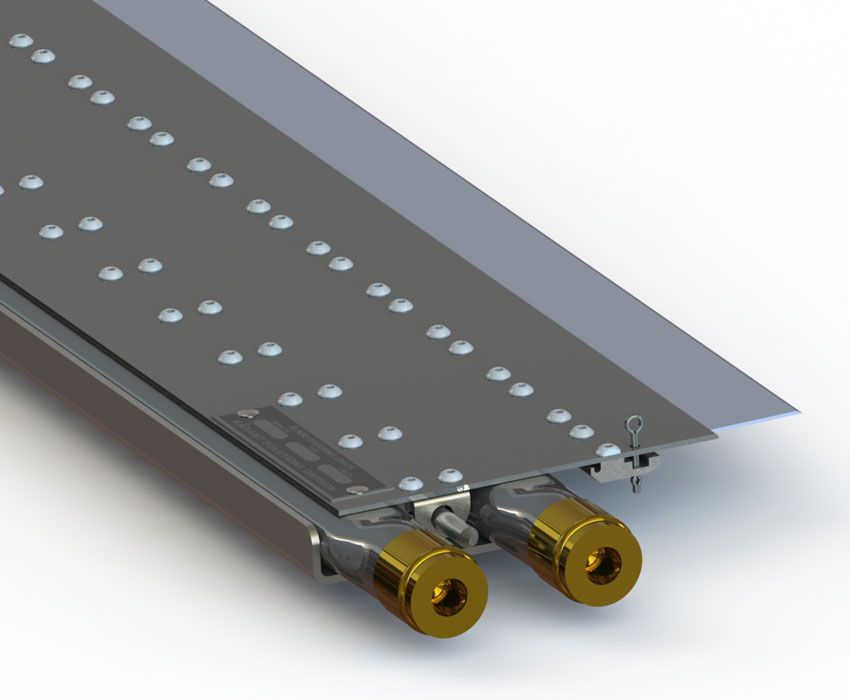

StaClean™ DST

Designed and manufactured for heavy-duty sheet shedding and cleaning applications on all paper machines and grades. Applications include press rolls, first dryers, and last dryers.

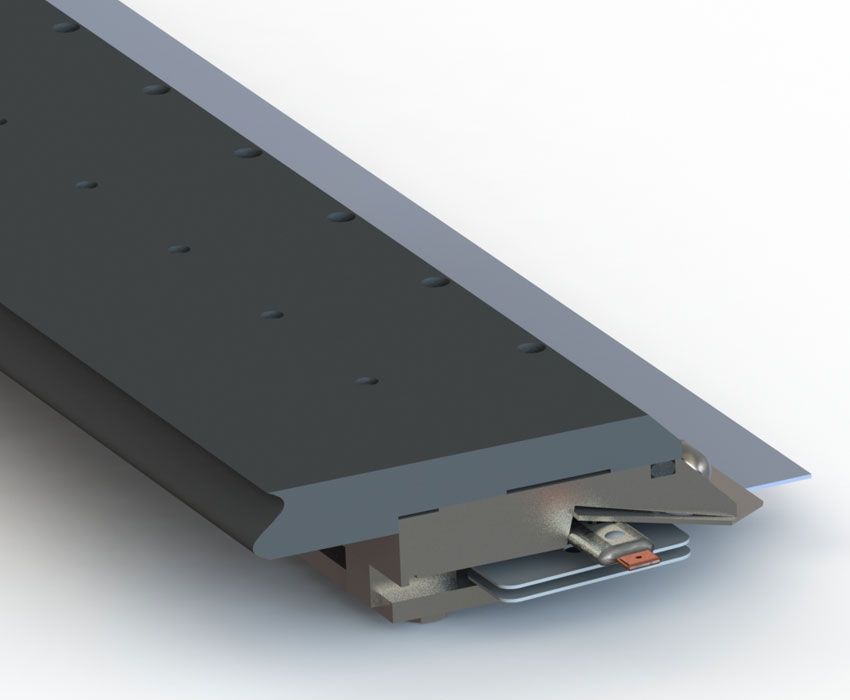

StaClean™ H

Uses precise blade pressure control with self-conforming top plate and is sealed against contamination. Applications include breast rolls, wire rolls, felt rolls, dryers, and calender rolls.

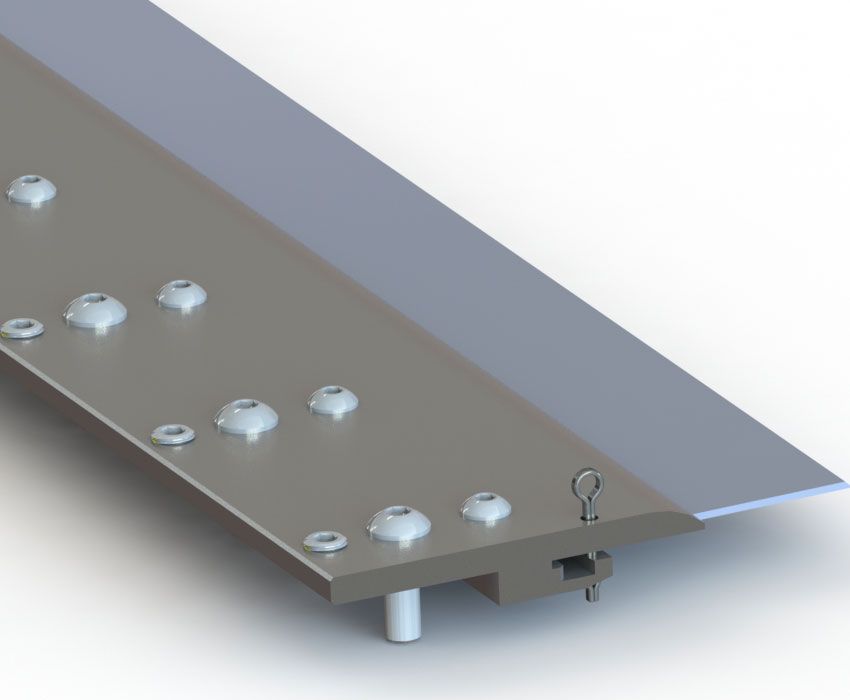

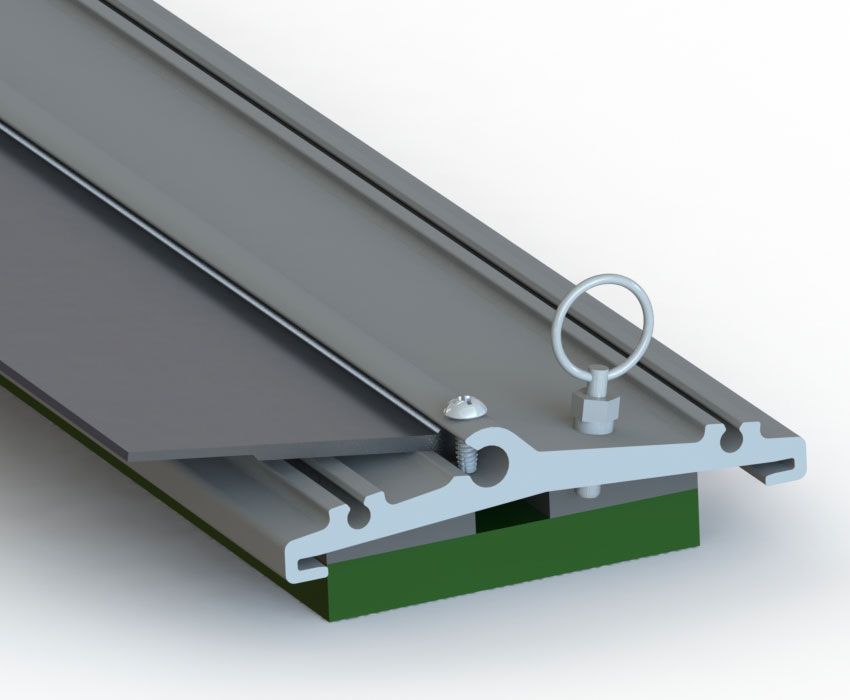

UniClean™ S

A low-profile tube loaded holder that provides uniform loading across the roll surface. DST or KF style blade retention fingers are optional. The holder features an integrated UniTrak™ holder removal system for quick and easy maintenance and cleaning. Applications include breast roll, wire rolls, felt rolls, dryers and calendar rolls.

UniFlex™

Robust design for high load applications that features an incompressible liquid conforming tube for even blade pressure across roll face. Applications include center press, first dryers, and last dryers.

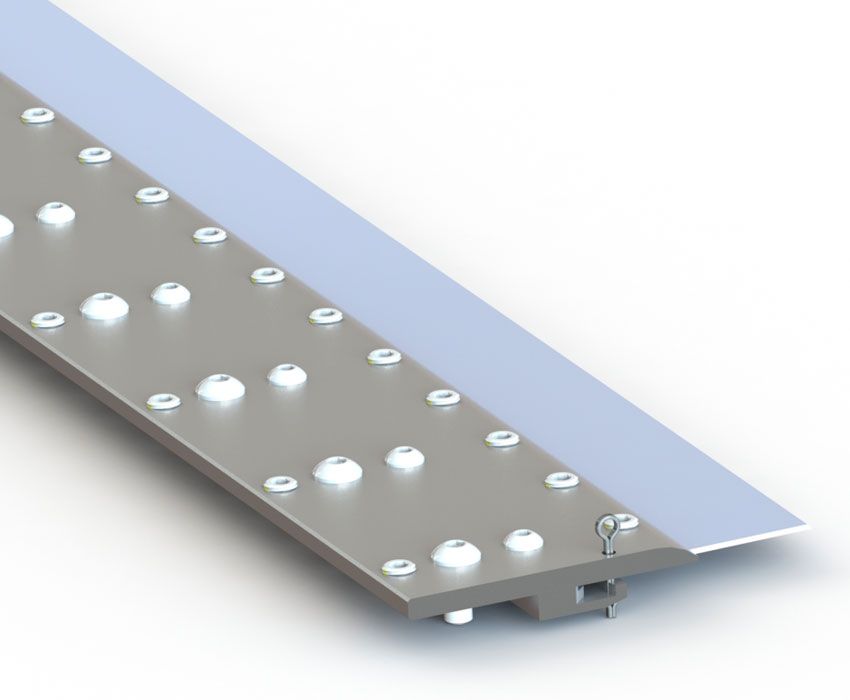

UniSlide™

Corrosion resistant composite construction features a built-in holder removal system that allows easy holder removal for cleaning and maintenance. Applications include wire rolls, felt rolls, dryers, and calender rolls.