Ceramic Tip Creping Blades

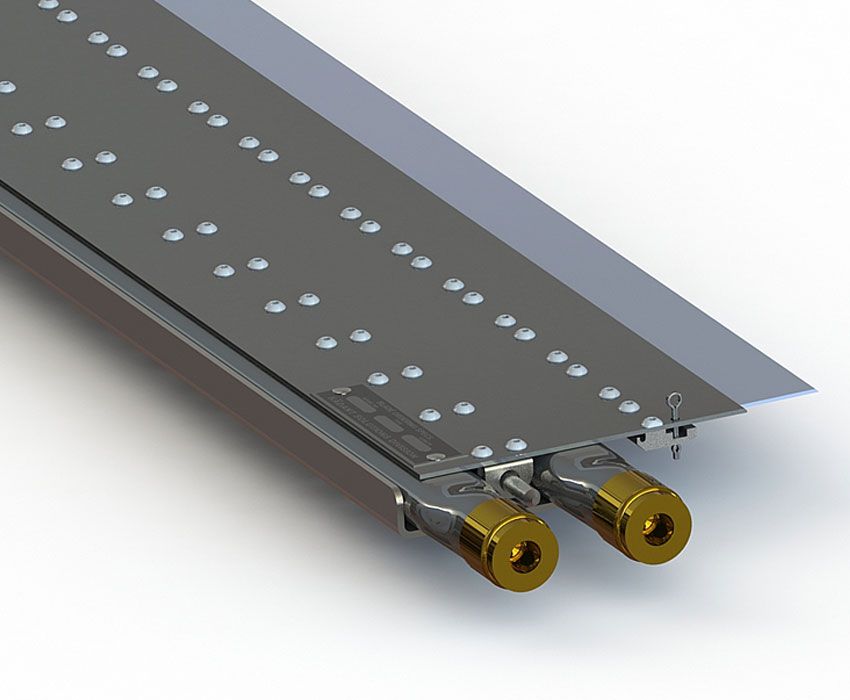

A ceramic tip creping blade is used in tissue production to add bulk, stretch, absorbency, and softness. A doctor or creping blade holder is used to load the blade against the Yankee, the heart of the tissue-making process. A ceramic tip creping blade helps create a smoother surface, which can lead to a finer crepe and better handfeel.

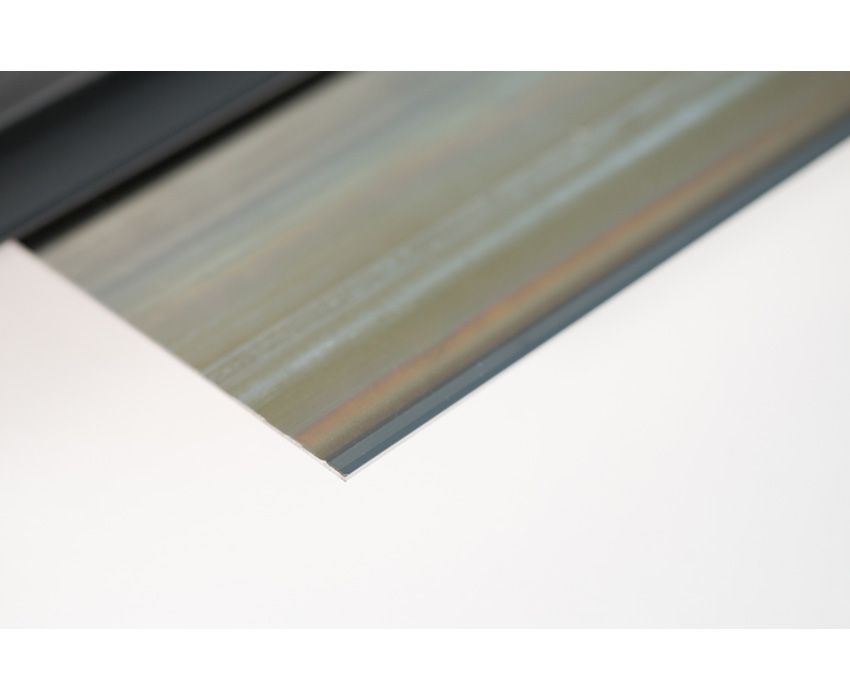

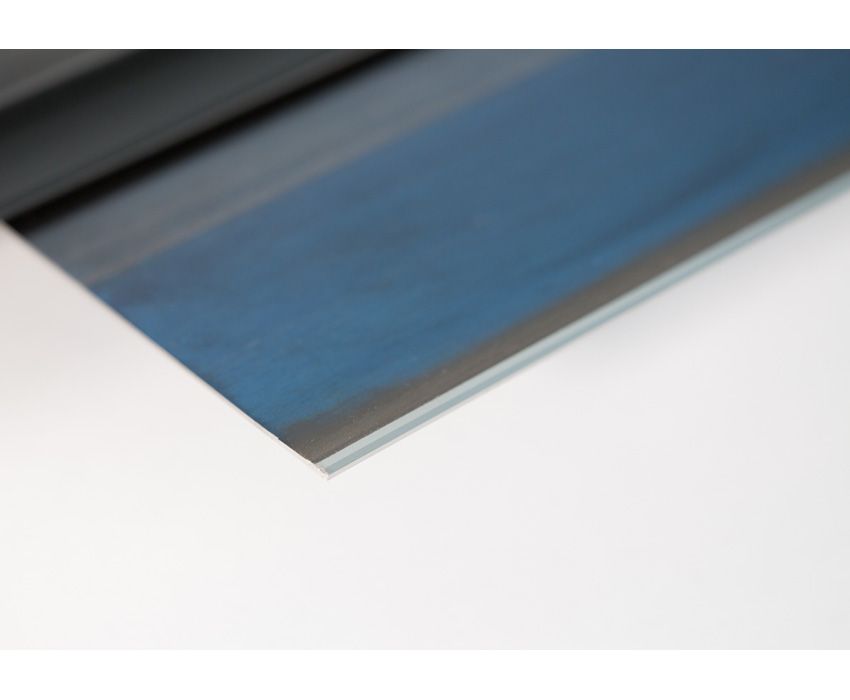

Unlike other ceramic creping blades, CeraEdge™ creping blades break in quickly and have a no-chip ceramic tip, making them an optimal choice for providing long life for tissue machine productivity. The CeraEdge S blade is recommended for applications where tissue softness is the main priority. The CeraEdge L blade is recommended when maximizing blade life is priority. Both CeraEdge blades provide stable performance for tissue production, are safer to the Yankee surface than traditional ceramic blades, and produce less dusting and linting due to a smoother wear edge.

CeraEdge L Features

-

Stable, optimum performance throughout blade life

-

Steady performance from blade to blade

-

Plastic protected blade edges

-

Packaged straight in wooden crates or coiled

-

Longest blade life of any blade available in the market today

CeraEdge S Features

-

Produces high softness levels

-

Stable, optimum performance throughout blade life

-

Steady performance from blade to blade

-

Plastic protected blade edges

-

Packaged straight in wooden crates or coiled

FAQ

Typically, a ceramic tip creping blade remains sharper and more durable than a traditional doctor blade. The CeraEdge creping blade is unique with its no-chip ceramic tip.

The key is picking the correct blade for the application. The wrong blade can damage a roll or allow a sheet to pass. Take into consideration the type of creping or doctoring system being used, the application on the machine, the roll material and hardness, and machine speed. Consult with a creping blade expert to learn more.

There are several factors that determine how often a ceramic tip creping blade will need to be changed. These include the machine application, temperature, roll material and hardness, and machine speed. Consult with a creping blade expert to learn more.