Electro-Mechanical Shower Oscillators

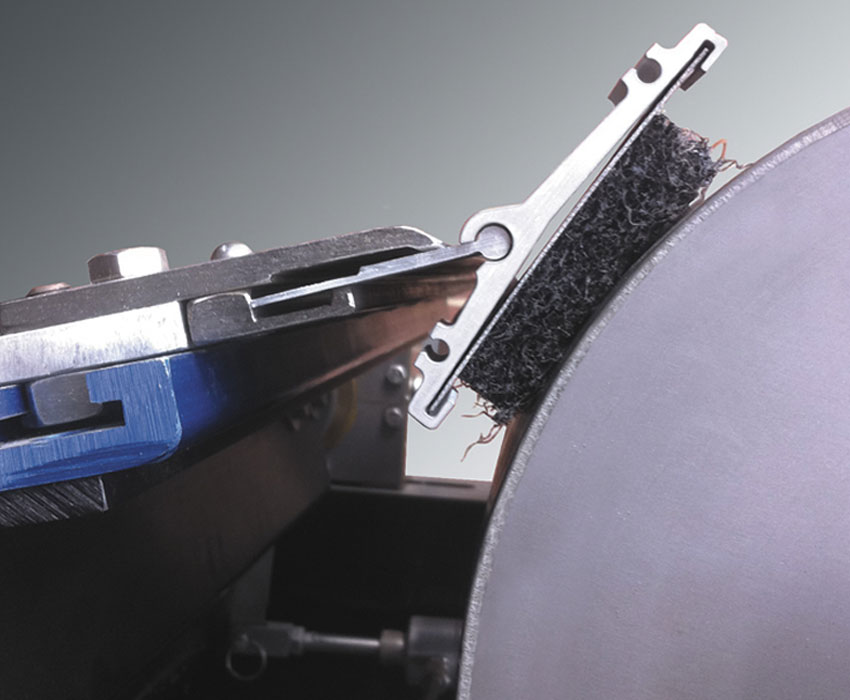

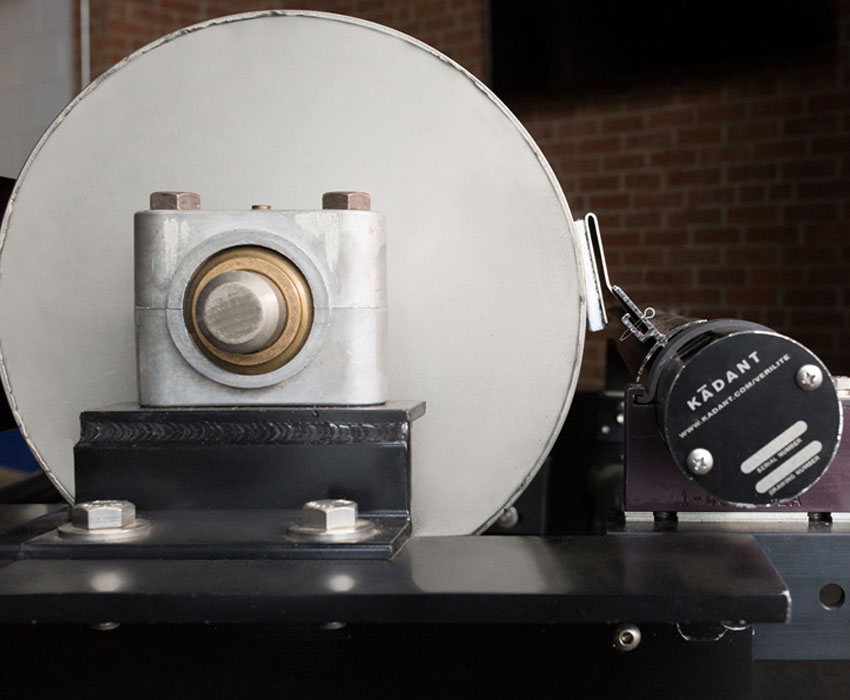

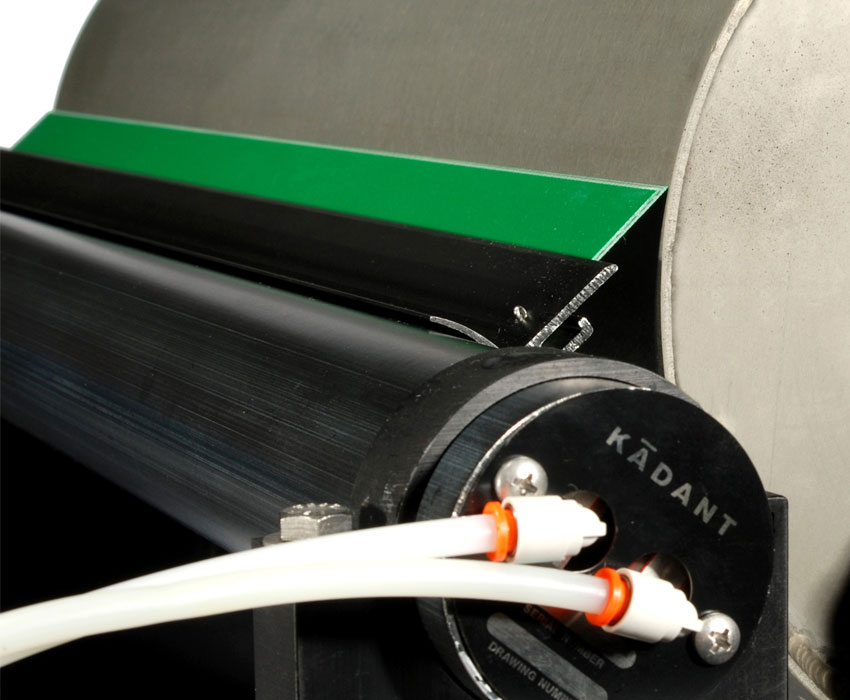

Electro-mechanical shower oscillators are precisely synchronized with the machine speed and fabric loop to ensure that 100% of the fabric is cleaned. Oscillating shower systems are critical to fabric, roll, or cylinder cleaning performance because they permit the use of higher intensity needle jet nozzles for deeper cleaning action or better flow distribution on lubrication or chemical applications.

Products

-

EMO III™ Electro-Mechanical Shower Oscillator

-

ArcDrive™ Electro-Mechanical Shower Oscillators

-

OutBack™ Electro-Mechanical Shower Oscillators

-

Genesis™ Ultra Electro-Mechanical Shower Oscillators