High-Pressure Shower Oscillation: It’s Not Just a Good Idea, It’s the Law!

It may not be an actual law, but cleaning and conditioning shower oscillation provides uniform coverage and prevents potential damage to the fabric from high-pressure jet streams.

Is shower oscillation really that important? The simple answer is yes and there are several reasons why. When considering a shower with jet nozzles, oscillation is important to evenly distribute the jet energy on the fabric or wire in the cross-machine direction (CMD).

Is shower oscillation really that important? The simple answer is yes and there are several reasons why. When considering a shower with jet nozzles, oscillation is important to evenly distribute the jet energy on the fabric or wire in the cross-machine direction (CMD).

The primary reason to oscillate a fan shower is to correct imperfections in nozzle spray patterns. For example, the normal flow distribution of all fan nozzles varies from 1% to 4%. The spray pattern is also dependent on fluid pressure, nozzle wear, and water contamination. These imperfections can lead to streaking which is when water is concentrated in one or multiple areas on the fabric or wire. This causes the sheet moisture profile to vary in the CMD. Additional reasons to oscillate a fan shower are to reduce sheet surface defects, extend the fabric or wire life, and clean fabrics that enhance drainage and overall forming, pressing, and dryer section performance.

Speed synchronization of the oscillator has a big impact on the shower cleaning results. A synchronized oscillator is when the speed of the oscillator matches the speed of the machine. This means the oscillator moves one nozzle diameter or width per revolution of the wire or fabric.

An unsynchronized oscillator, shown to the right, can cause uneven cleaning of the fabric or wire and water streaking on the sheet. An oscillator with minimal dwell time can help prevent these problems.

An unsynchronized oscillator, shown to the right, can cause uneven cleaning of the fabric or wire and water streaking on the sheet. An oscillator with minimal dwell time can help prevent these problems.

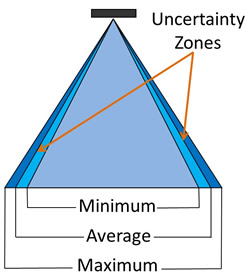

The following equation can be used to ensure proper oscillator speed:

Oscillator Speed = (Machine Speed X Nozzle Diameter) ÷ Fabric Length

This equation calculates the required oscillator speed advancing the nozzles one diameter or fabric revolution providing uniform coverage.

The oscillator stroke length is another important shower system attribute. Oscillator stroke is the distance the shower moves in the cross-machine direction and is application-dependent. If the oscillator stroke length is not designed properly, the shower will not effectively clean or apply the correct volume of fluid. An application may require single coverage (one nozzle traveling in the CMD equal to the nozzle spacing), double coverage (one nozzle traveling in the CMD equal to two times the nozzle spacing), and so on. The oscillator stroke can be calculated using the following formula:

The oscillator stroke length is another important shower system attribute. Oscillator stroke is the distance the shower moves in the cross-machine direction and is application-dependent. If the oscillator stroke length is not designed properly, the shower will not effectively clean or apply the correct volume of fluid. An application may require single coverage (one nozzle traveling in the CMD equal to the nozzle spacing), double coverage (one nozzle traveling in the CMD equal to two times the nozzle spacing), and so on. The oscillator stroke can be calculated using the following formula:

Oscillator Stroke = Coverage X Nozzle Spacing

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.