How Are Lithium-ion Batteries Manufactured?

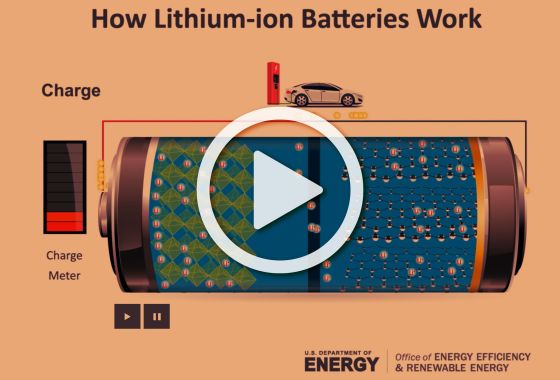

A lithium-ion battery works by moving lithium ions back and forth between two parts called the anode and the cathode.

When the battery is providing power, the lithium ions move from the anode to the cathode, creating a flow of electricity that provides power. When charging the battery, the ions move back to the anode, getting ready to provide power again. This back-and-forth movement of ions is what makes the lithium-ion battery reusable and powerful. The following animation depicts how a lithium-ion battery works is courtesy of the U.S. Department of Energy.

Due to their high energy density, rechargeability, and long life span, lithium-ion batteries can power various devices, from smartphones to electric vehicles (EV). Have you ever wondered how a lithium-ion battery is manufactured and ends up in the EV you are driving? Continue reading to learn how a lithium-ion battery is manufactured

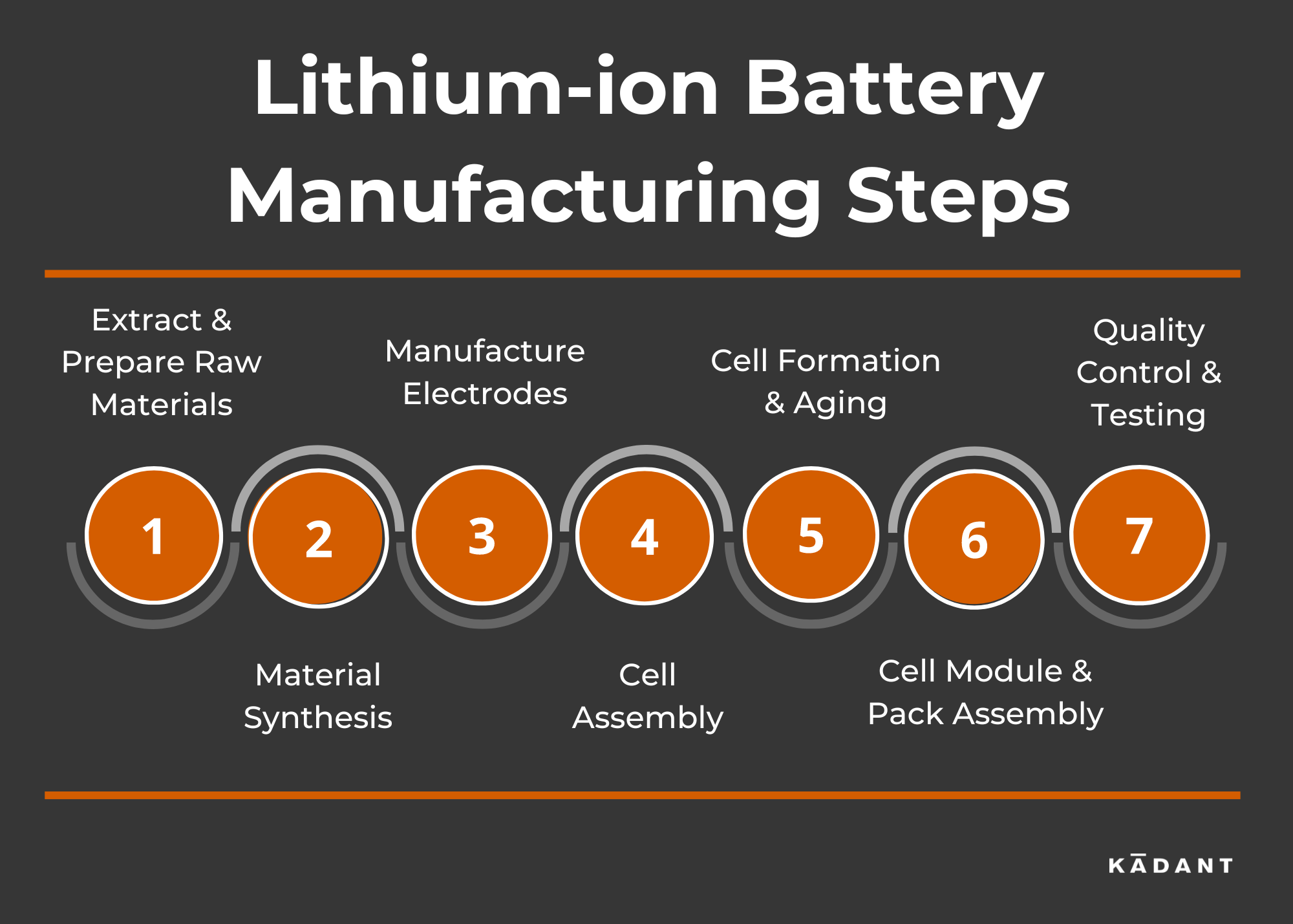

The production of lithium-ion batteries involves sophisticated chemical, mechanical, and electrical processes to ensure safety, efficiency, and performance. Let’s examine the complex process of lithium-ion battery production, from raw material extraction to the final assembly of the battery cells. The following outlines the key stages of creating a lithium-ion battery, including material preparation, cell assembly, and quality control.

Step 1: Raw Material Extraction & Preparation

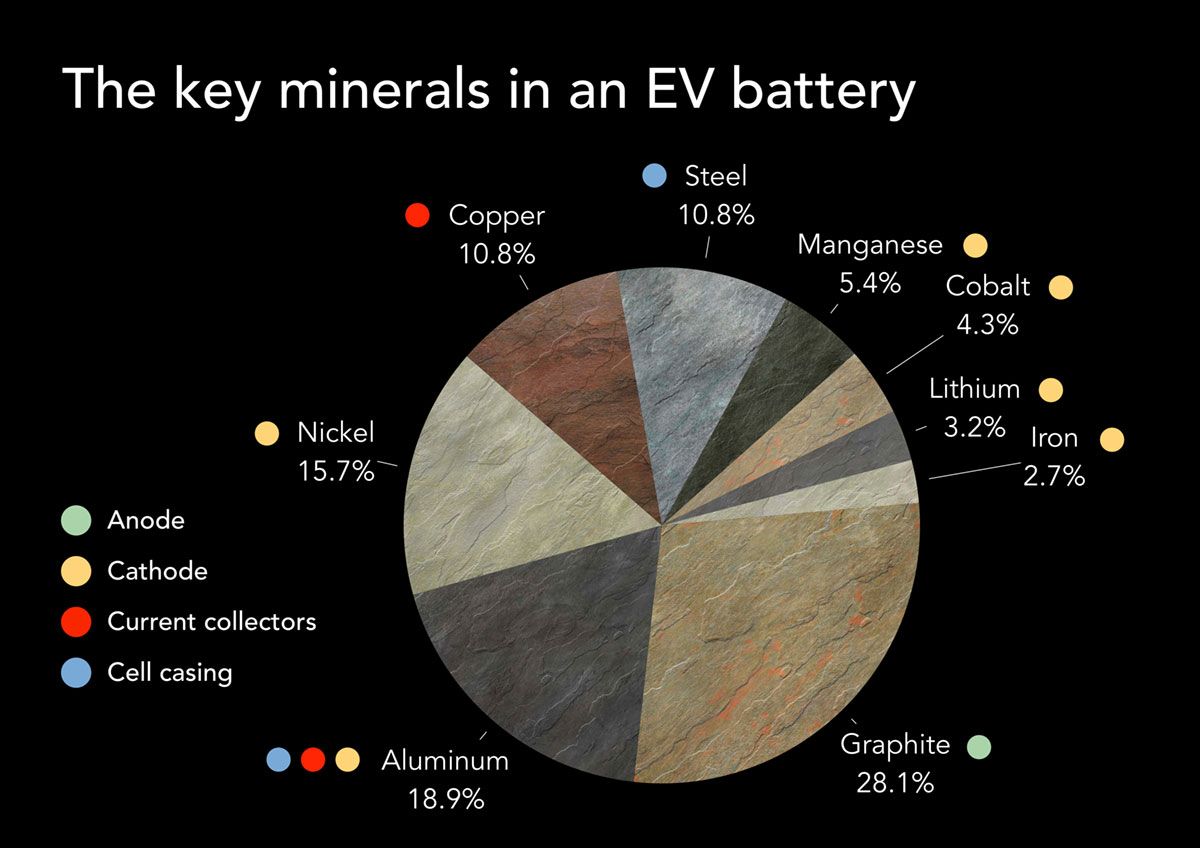

The first step in lithium-ion battery production is the extraction of raw materials. According to the National Renewable Energy Laboratory, “Critical raw materials used in manufacturing [lithium-ion] batteries include lithium, graphite, cobalt, and manganese.” Inside the lithium-ion battery are the anode and cathode electrodes which allow for the flow of electric charge. The anode is often constructed from a carbon-based material such as graphite. The cathode is made from metal oxides such as lithium, cobalt, and manganese.

Step 2: Active Material Synthesis

Step 3: Electrode Manufacturing

Manufacturing the electrode is the third step, which involves slurry preparation, coating and drying, and calendering. In slurry preparation, the active materials for either the anode or the cathode are mixed with a solvent and binder to create the slurry. The slurry is then coated onto a metal foil (typically copper for the anode and aluminum for the cathode) and dried in a controlled environment to remove the solvent. Finally, the coated foils are passed through rolls to achieve the desired thickness and density. This is called calendering.

Kadant’s Role

This is the point in the lithium-ion battery manufacturing process where Kadant steps in to improve the process and end product. As mentioned above once the slurry, coating, and drying takes place, the coated foils are passed through a series of rolls called calendering. Kadant supplies a unique, compact, continuous roll cleaner to keep the rolls free of contaminates. To learn more about the VeriLite™ roll cleaner assembly and its use in lithium-ion battery production, check out the article, “Kadant Solutions Plays a Critical Role in Lithium-ion Battery Production.”

Step 4: Cell Assembly

Step 5: Cell Formation & Aging

Step 6: Cell Module & Pack Assembly

Step 7: Quality Control & Testing

Resources

- Igogo, T., Sandor, D., Mayyas, A., & Engel-Cox, J. (2019). Supply Chain of Raw Materials Used in the Manufacturing of Light-Duty Vehicle Lithium-Ion Batteries.

- Minos, S. (2023, February 28). How Lithium-ion Batteries Work. Energy.gov; US Department of Energy.

- What Are Battery Anode and Cathode Materials? (2023, April 26). AquaMetals.

- com | Batteries Step by Step: The Li-Ion Cell Production Process. (2023, September 8). Batteryline.com.

- National Academies of Sciences, Engineering, and Medicine. Lithium Ion Batteries and Their Manufacturing Challenges. The National Academies Press, 2014.

- Minos, S. (2023, February 28). How Lithium-ion Batteries Work. Energy.gov; US Department of Energy.

- Writer, T. S. (2023, May 2). A Deep Dive into Lithium-Ion Battery (LIB) Manufacturing. THORS ELearning Solutions.

- Lithium Battery Company. How It’s Made - Lithium Ion Batteries. YouTube, 2018.

- How It’s Made. How It’s Made Lithium Batteries. YouTube, 2016.

- LG Energy Solution. How Batteries are Made: Electrode Manufacturing – Mixing. LinkedIn, 2024.

- LG Energy Solution. How Batteries are Made: Electrode Manufacturing – Coating. LinkedIn, 2024.