Ways to Avoid Debris During Anode & Cathode Production and Improve ROI

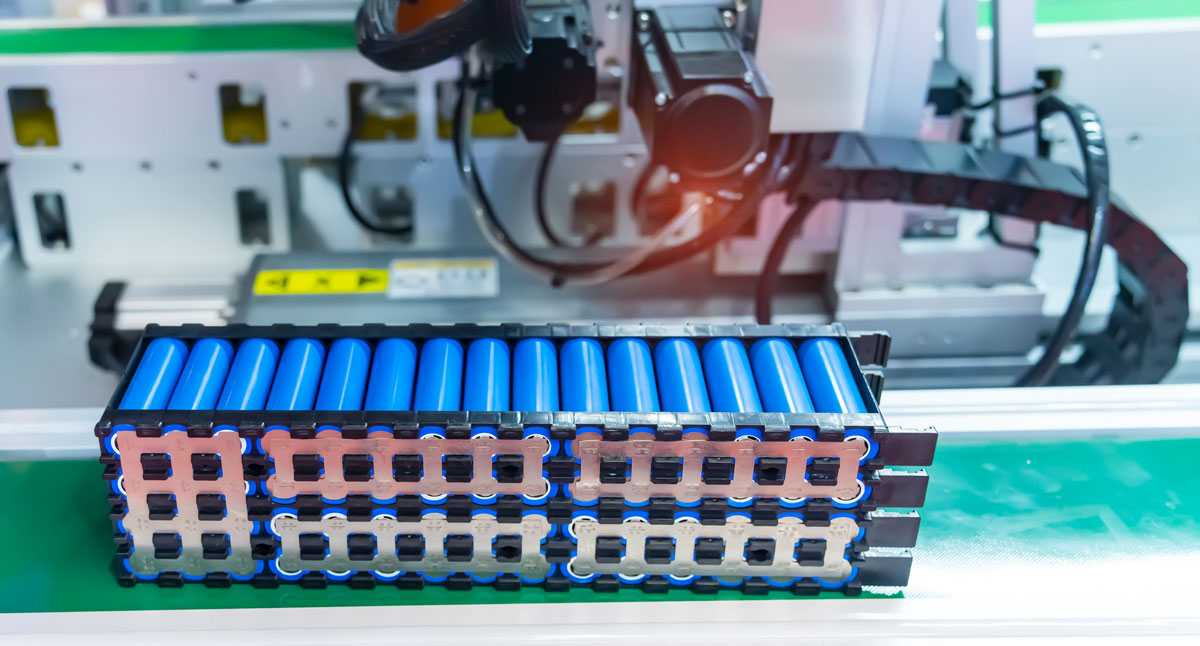

Avoiding debris in the production of anodes and cathodes can lead to improved uptime, productivity, and operator safety. What methods can be used to avoid debris in lithium-ion battery manufacturing in the first place? There are several options including clean room environments, automated inspection systems, and preventative maintenance and cleaning.

Clean Manufacturing Locations

Manufacturing anodes and cathodes for lithium-ion batteries in clean manufacturing conditions can ensure a high quality, reliability final product. These clean environments are specially designed to maintain low levels of pollutants, such as dust, airborne microbes, aerosol particles, and chemical vapors. In electrode manufacturing, operating in a clean area, conditions significantly reduces the risk of contaminants infiltrating the electrode materials or coating processes.

Automated Inspection Systems

The integration of automated inspection systems into the production line allows for real-time monitoring and quality control of anode and cathode manufacturing. These systems use advanced imaging technologies, such as high-resolution cameras and laser scanning. The key advantage of these systems is their ability to rapidly and accurately identify defects that might not be visible to the human eye or would be impractical to check manually in large-scale production.

Preventive Maintenance and Roll Cleaning

Regular maintenance and cleaning of the equipment used in anode and cathode manufacturing are vital for preventing the buildup of debris and contaminants that could interfere with the production processes.

Using roll cleaning systems such as the VeriLite™ roll cleaner assembly is a specific preventive measure that helps maintain the optimal performance of the rollers used in the coating and calendering processes. These systems automatically remove accumulated materials and contaminants from the roll, ensuring consistent application of electrode materials and preventing defects in the electrode films.

Together, these strategies form a comprehensive approach to minimizing the impact of debris and contaminants in the manufacturing of anodes and cathodes, crucial for the production of high-performance and reliable lithium-ion batteries.

Resources

- Ultimate Guide Cathode and Anode of the Battery. (n.d.). Ufine Battery.

- What Are Battery Anode and Cathode Materials? (2023, April 26). AquaMetals.

- National Academies of Sciences, Engineering, and Medicine. Lithium Ion Batteries and Their Manufacturing Challenges. The National Academies Press, 2014.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.