How are Anodes and Cathodes Manufactured?

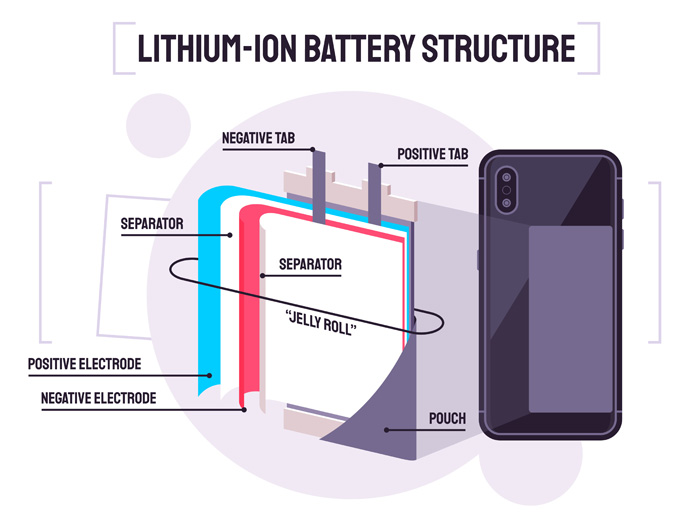

The electrodes, which consist of thin layers known as the anode and cathode, are central to the production of lithium-ion batteries. Each layer is created separately but in a similar manufacturing process.

Many anode and cathode manufacturing facilities use a calendering process to adhere a precise thickness of chemistry to a metal substrate. It is critical that these calender rolls remain clean and free of any type of debris. This includes the residue buildup, which can lead to defects and significantly damage a roll’s surface, leading to costly replacements and downtime.

Companies and researchers continue to develop and commercialize the dry electrode manufacturing process. In contrast to the conventional wet process, that involves slurry preparation, coating, and drying prior to the calendering process.

In slurry preparation the active materials are mixed with a solvent and binder, then, it is coated onto the appropriate metal foil and dried in a controlled environment to remove the solvent. Once the slurry, coating, and drying takes place, the coated foils are passed through a series of calender rolls.

During the calendering process, oils escape from the film and the dirt particles on the roll must be removed to ensure production quality of the lithium-ion battery.

With a focus on sustainable energy, Kadant has developed a unique, compact, continuous roll cleaner to keep the calender rolls free of debris. The VeriLite™ roll cleaner assembly works continuously during the production run, therefore, no need for manual roll cleaning; improving uptime and safety. An intact battery film is crucial for a functioning battery, continuous roll cleaning is one of the critical steps in ensuring this and helps to increase process reliability and minimize the reject rate.

Resources

- What Are Battery Anode and Cathode Materials? (2023, April 26). AquaMetals.

- Why dry coating electrodes is the future of the electric vehicle battery industry. (2021, December 3). Electric & Hybrid Vehicle Technology International.

- Dry manufacturing process offers path to cleaner, more affordable high-energy EV batteries | ORNL. (n.d.). Www.ornl.gov.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.