How Does Debris Affect Anode and Cathode Production?

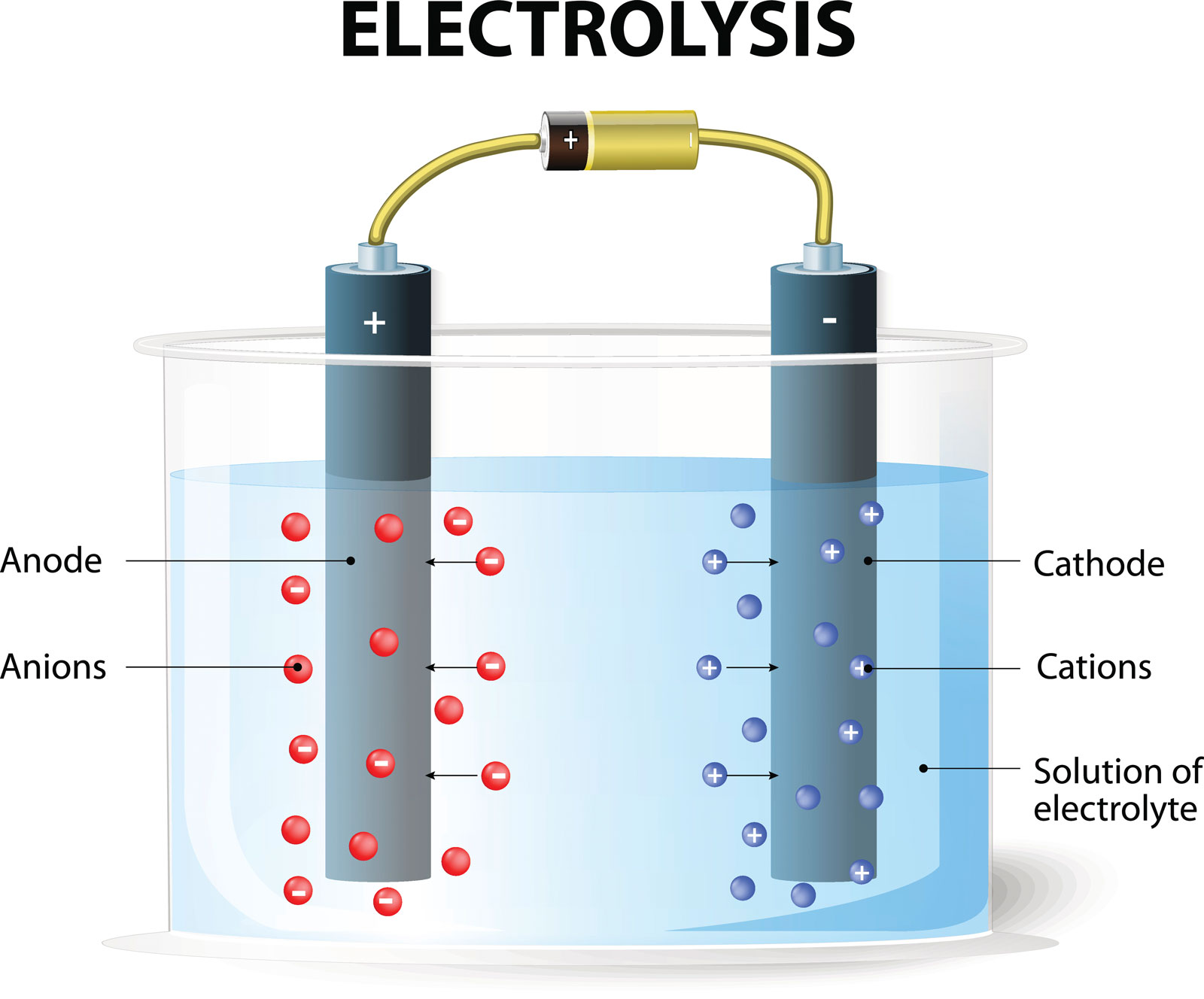

Anodes and cathodes are the two principal electrodes in lithium-ion batteries and are how the battery is able to store and release electrical energy. Lithium-ions move between the anodes and cathodes during the charge and discharge cycles.

Industrial hygiene and cleanliness standards play a crucial role in lithium-ion battery manufacturing. Many producers have yet to address the challenges with the accumulation of debris and other residues on roll surfaces, that come into contact with the product. This is especially true for the calendering process of anode and cathode production. Any impurity or imperfection in an anode or cathode layer could impact battery performance.

Can Debris Ruin Your Production Process?

Yes. Especially when the calender or other rolls become contaminated with debris or oils; causing defects in the quality of the finished product (anodes and cathodes) and/or damage to the roll itself is a likely outcome.

Wired  magazine highlights that there have been large consumer product recalls traced back to impurities in the electrodes: the Samsung S7 and hoverboards. While my family avoided the cell phone issue, the hoverboard caused many tears as our favorite toy was retired.

magazine highlights that there have been large consumer product recalls traced back to impurities in the electrodes: the Samsung S7 and hoverboards. While my family avoided the cell phone issue, the hoverboard caused many tears as our favorite toy was retired.

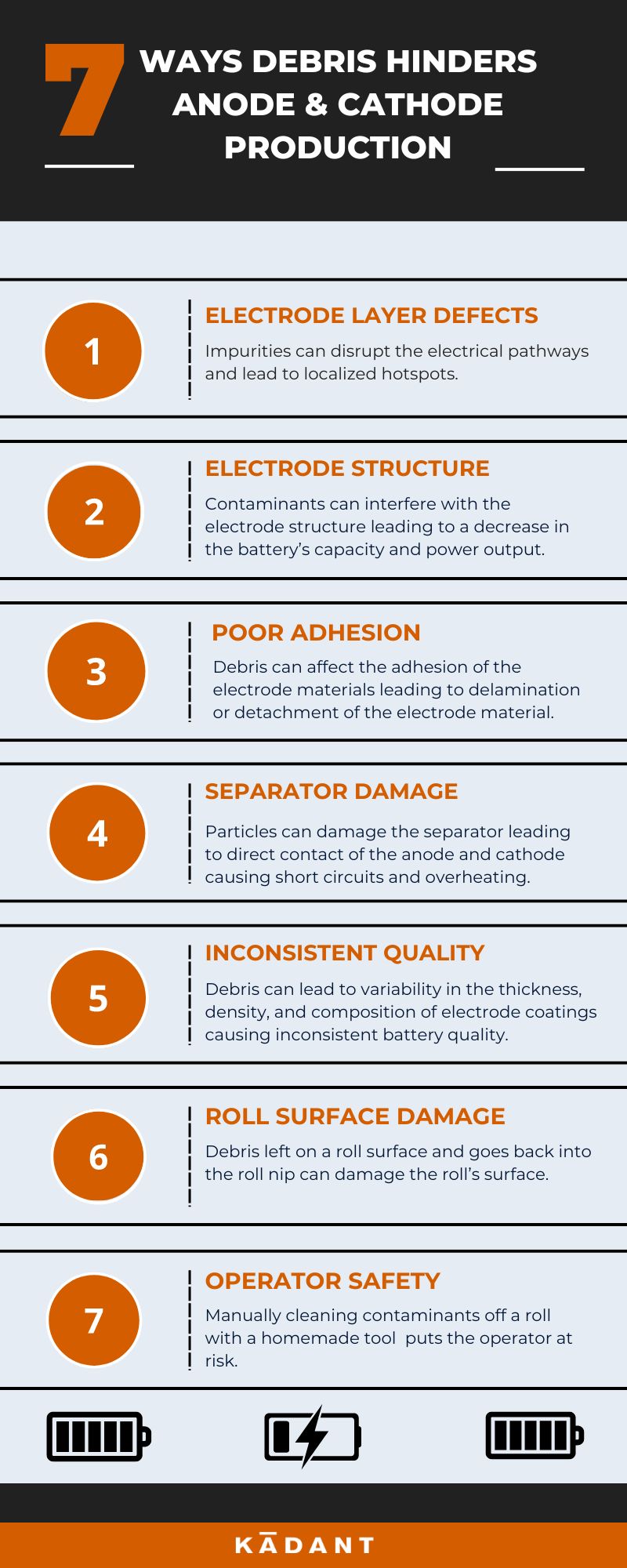

Let’s explore seven areas in anode and cathode production that can be hindered by debris.

- Debris can lead to defects in the electrode layers, such as inhomogeneities or impurities, which can disrupt the electrical pathways and lead to localized hotspots. This decreases battery efficiency and increases the risk of failure.

- Contaminants can also interfere with the electrode structure leading to a decrease in the battery's capacity and power output, as well as an increase in internal resistance, which can cause the battery to heat up during use.

- Debris can affect the adhesion of the electrode material to the current collectors (copper for anodes, aluminum for cathodes). Poor adhesion results in delamination or detachment of the electrode material, compromising the battery's structural integrity and leading to a loss of electrical connectivity, which drastically reduces the battery's lifespan and reliability.

- Particles of debris can damage the separator—a critical component that keeps the anode and cathode apart to prevent short circuits. A damaged separator can lead to a direct contact between the anode and cathode, causing short circuits, overheating, and in extreme cases, thermal runaway, leading to fires or explosions.

- The presence of debris can lead to variability in the thickness, density, and composition of the electrode coatings, resulting in inconsistent battery quality. Batteries produced under such conditions can exhibit a wide range of performance characteristics, making it difficult to ensure reliability and specification requirements.

- Debris that is not cleaned off the roll surface and goes back into the roll nip can damage the roll surface. This will lead to more product defects, greater costs, and increased downtime for roll replacement.

We cannot overlook operator safety. Often, to combat debris, operators will shut down production and try to manually clean the rolls surface with a homemade tool. This not only delays production but causes safety issues for the operator when putting a handmade tool, often some kind of scraper taped to a broom handle, inside the production environment.

We cannot overlook operator safety. Often, to combat debris, operators will shut down production and try to manually clean the rolls surface with a homemade tool. This not only delays production but causes safety issues for the operator when putting a handmade tool, often some kind of scraper taped to a broom handle, inside the production environment.

If the calender or other rolls aren’t continuously cleaned during production, more than just your bottom line may be at risk.

Mitigation Strategies

To mitigate the effects of debris on anode and cathode production, manufacturers have employed several strategies such as clean room environments, automated inspection systems, and preventative maintenance and cleaning.

One of the preventative tools, is the VeriLite™ roll cleaner assembly, a proven, reliable solution for combating debris and enhancing operator safety in the calendering process. The VeriLite roll cleaner assembly’s compact, durable design makes it ideally suited for the tight spaces in electrode production. It runs continuously during production, removing the risk of operator injury while improving uptime and productivity.

By ensuring a clean process and employing strict quality control measures are crucial for minimizing the impact of debris on the manufacturing of anodes and cathodes, thereby enhancing the performance, reliability, and safety of lithium-ion batteries and those producing them.

Resources

- Moynihan, T. (2017, January 23). Samsung Finally Reveals Why the Galaxy Note 7 Kept Exploding. WIRED.

- Samsung Recalls Galaxy Note7 Smartphones Due to Serious Fire and Burn Hazards. (2016, September 19). U.S. Consumer Product Safety Commission.

- Ultimate Guide Cathode and Anode of the Battery. (n.d.). Ufine Battery.

- What Are Battery Anode and Cathode Materials? (2023, April 26). AquaMetals.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.