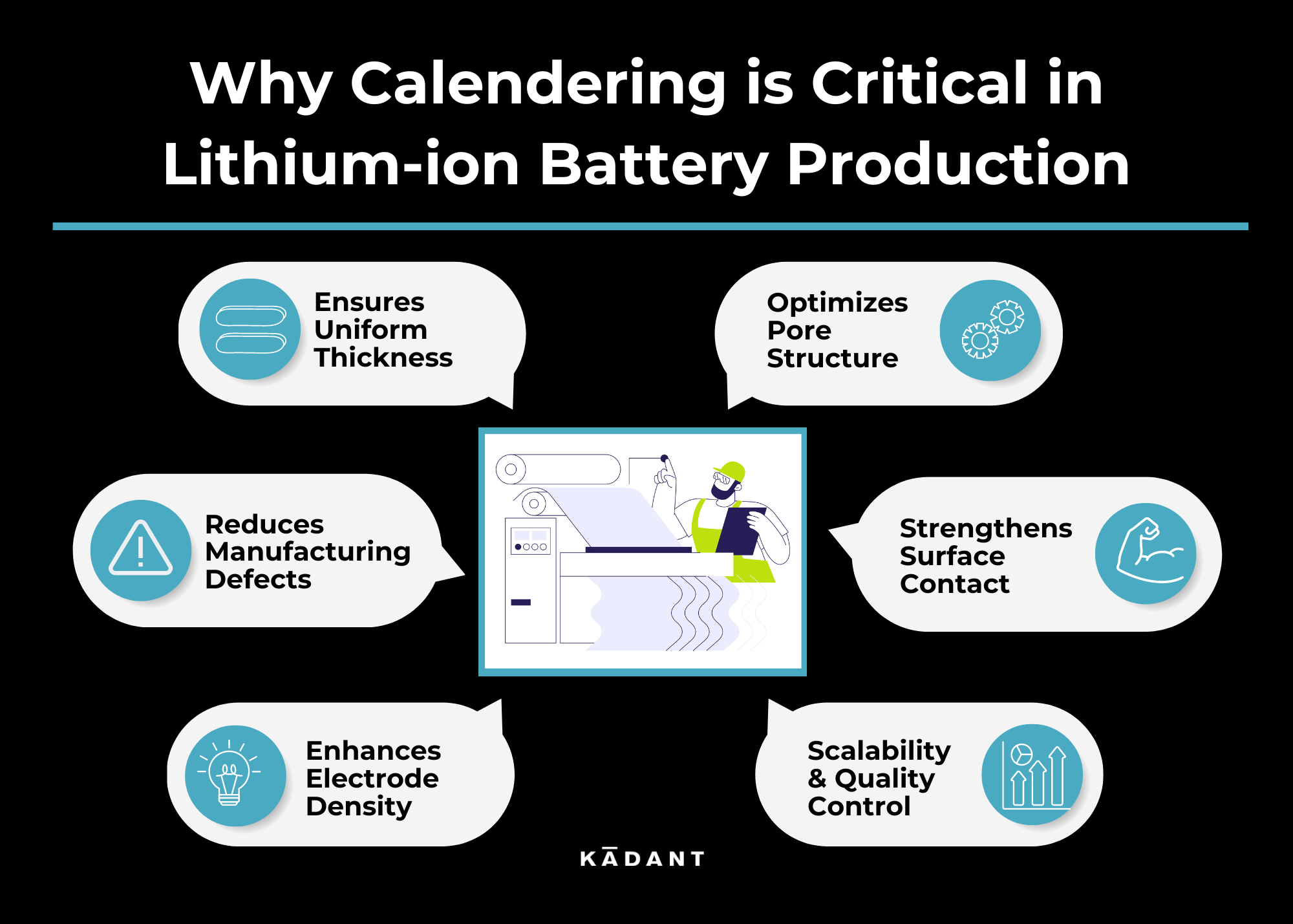

Why Is Calendering Critical in the Production of Lithium-Ion Batteries?

Calendering in lithium-ion battery production is when the anode and cathode electrode sheets are pressed through a series of rollers to compress and densify the material. Further proving that calendering is critical due to its role in optimizing the quality of the anode and cathode electrodes. Anode and cathode electrodes significantly impact the overall performance, efficiency, and reliability of the batteries. Let's examine the essential functions of calendering in more detail.

1. Enhances Electrode Density

The primary purpose of calendering is to increase the density of the electrode materials. This compression is essential to maximize the amount of active material per unit volume, allowing for a greater energy storage capacity within the same physical space. Higher density anode and cathode electrodes can store more energy. This contributes to longer battery life and greater energy output, which are crucial factors for applications like electric vehicles and portable electronic devices.

2. Ensures Uniform Thickness

Uniformity in anode and cathode electrode thickness is crucial for consistent battery performance. Variations in thickness can lead to uneven current distribution during charging and discharging, which might result in localized hot spots, reduced efficiency, and faster degradation of the battery. Calendering ensures that the anode and cathode electrode layers are uniformly thick, promoting even ion flow and stable battery operation.

3. Strengthens Surface Contact

Good adhesion between the anode and cathode materials and the current collectors is crucial for efficient electron flow. Calendering helps strengthen the mechanical bond between the active material and the current collector, which reduces internal resistance and improves electrical conductivity. This leads to better charge-discharge efficiency and longer battery life.

4. Optimizes Pore Structure

The proper pore structure in the anode and cathode electrodes is crucial for the infiltration of the electrolyte and for facilitating the smooth flow of lithium ions during operation. Calendering helps to control the absorption of the electrode materials, balancing between having enough pores for electrolyte access and maintaining sufficient contact between particles for electronic conduction.

5. Reduces Manufacturing Defects

By ensuring consistent and defect-free anode and cathode electrode films, calendering reduces the risk of manufacturing flaws that can lead to battery failures. Defects like cracks, delamination, or uneven material distribution can cause short circuits, capacity loss, and other reliability issues.

6. Scalability and Quality Control

In large-scale production, maintaining high-quality and consistent battery components is essential. Calendering is a scalable process that can be tightly controlled and monitored, making it ideal for mass production settings. It allows manufacturers to achieve consistent product quality, reducing variability and ensuring that every battery meets stringent performance standards.

Calendering is pivotal in lithium-ion battery manufacturing due to its significant impact on the structural and functional integrity of the anode and cathode electrodes. By optimizing the physical characteristics of the anode and cathode, calendering enhances the battery's capacity, safety, and longevity, which are critical for meeting the increasing demands of modern battery applications.

The calendering process in the lithium-ion battery manufacturing is where Kadant’s roll cleaning technology improves production and the end product. The VeriLite™ roll cleaner assembly is a unique, compact, continuous roll cleaner designed to keep the calender rolls free of debris. Check out the article, “Kadant Solutions Plays a Critical Role in Lithium-ion Battery Production,” to learn more about our role in lithium-ion battery manufacturing.

Resources

- Blanchette, C. (2021, February 25). How Lithium-Ion Battery Manufacturers Can Conquer Separator Film, Coating, and Calendering. Advancing Materials.

- Minos, S. (2023, February 28). How Lithium-ion Batteries Work. Energy.gov; US Department of Energy.

- Battery electrode calendering process. (n.d.). Www.linkedin.com.

- CIDETEC. (2021, July 26). 3. Calendering. YouTube.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.