What are Anodes and Cathodes in Lithium-ion Batteries?

Anode and cathodes are terms used to describe the chemical reaction facilitating the flow of electric charge that occurs in a battery electrode. Not all batteries are rechargeable; most content defines an electrode as either the anode or the cathode. The truth is, depending on whether the battery cell is charging or discharging, the electrode can technically be either an anode or the cathode. In this article, we will be focusing on the battery cell in its discharging state only.

What’s an Anode?

During the lithium-ion battery discharge cycle, the anode functions as the negative electrode. It releases lithium ions during discharge and receives lithium ions during charge. Graphite is the most commonly used material in current lithium-ion batteries. Research is being done on other materials, including silicon and lithium metal, because of their potential to increase the battery's energy density.

What’s a Cathode?

The cathode serves as the positive electrode during the battery's discharge cycle. It accept lithium ions during discharge and release them during charging. Common cathode materials include cobalt, nickel, and manganese, each with different cost, energy density, safety, and lifespan characteristics.

Anodes and Cathodes Working Together

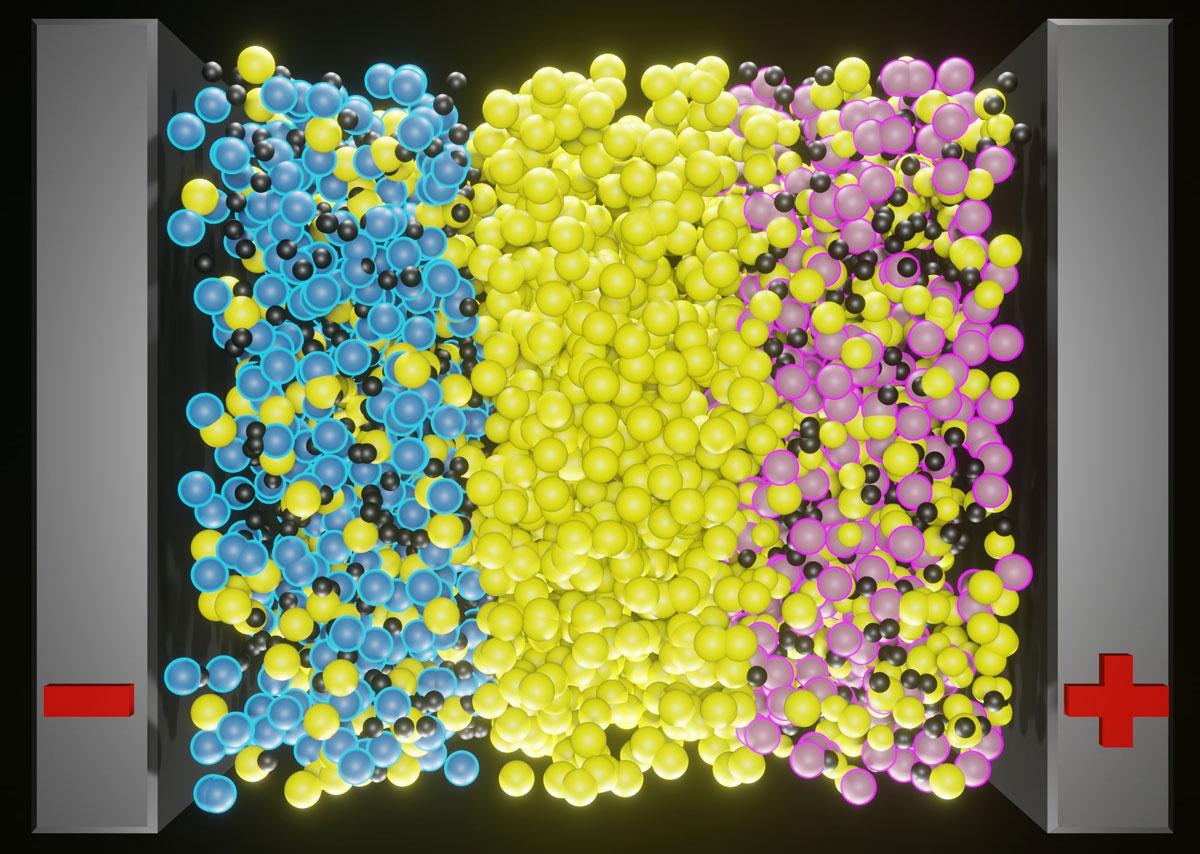

Inside the battery cell, lithium ions are constantly flowing from one electrode to the other. It is always from anode to cathode, that’s because an anode is defined as the electrode where the chemical reaction that gives up electrons is occurring.

If an electrode is losing electrons, it also has to release ions in order to stay electrically balanced. Lithium-ions move through the electrolyte within the battery cell. The electrons move through the external circuit connected to the battery electrodes via positive and negative terminals.

Anodes and cathodes are critical to the functioning of a lithium-ion battery. It is important that they are produced in a safe, debris-free process. Kadant offers the unique, compact, and continuous VeriLite™ roll cleaner assembly, which is ideal for keeping rolls debris free for longer uptimes. It also eliminates the need for manual roll cleaning, enhancing operator safety. By eliminating debris and minimizing manual cleaning, the VeriLite roll cleaner assembly not only enhances production uptime but also significantly improves operator safety.

As we continue to move towards a lithium-ion powered world, the roles of anodes and cathodes, along with the technologies used in their production, will remain at the forefront of innovation in energy storage solutions.

Resources

- Nobel Prize in Chemistry 2019: They developed the world’s most powerful battery.

- (2023, March 14). Anode, cathode, positive and negative: battery basics.

- Minos, S. (2023, February 28). How Lithium-ion Batteries Work.gov.

- LG Energy Solution. How Batteries are Made: Electrode Manufacturing – Mixing. LinkedIn, 2024.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.