Metals Processing

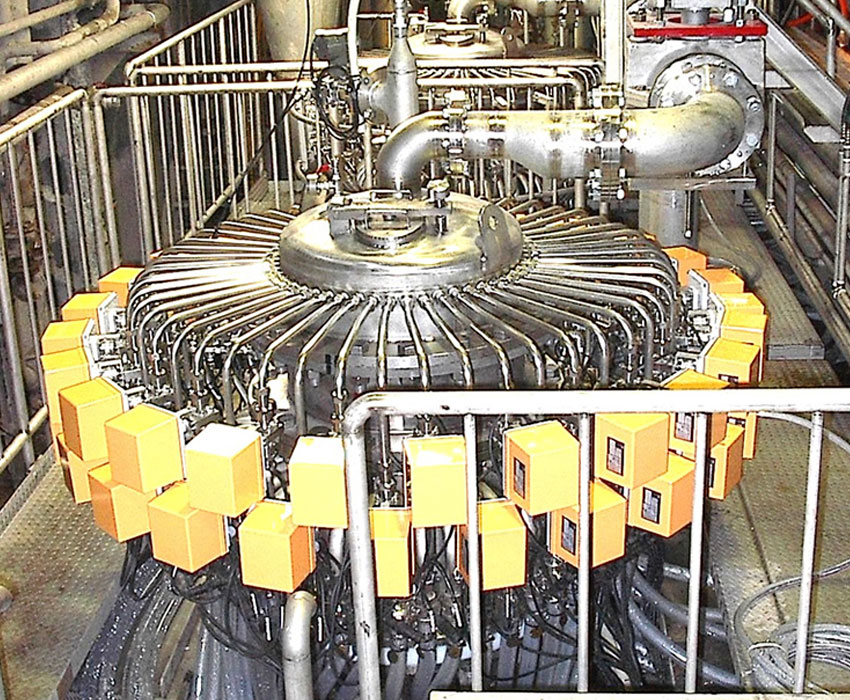

Kadant products are used in various metal industry applications, including rolling mills, galvanizing, coating, and painting. New technologies in new roll cleaning systems increases efficiency, reduces waste, enhances quality, and promotes sustainability.

Roll Cleaner Assemblies

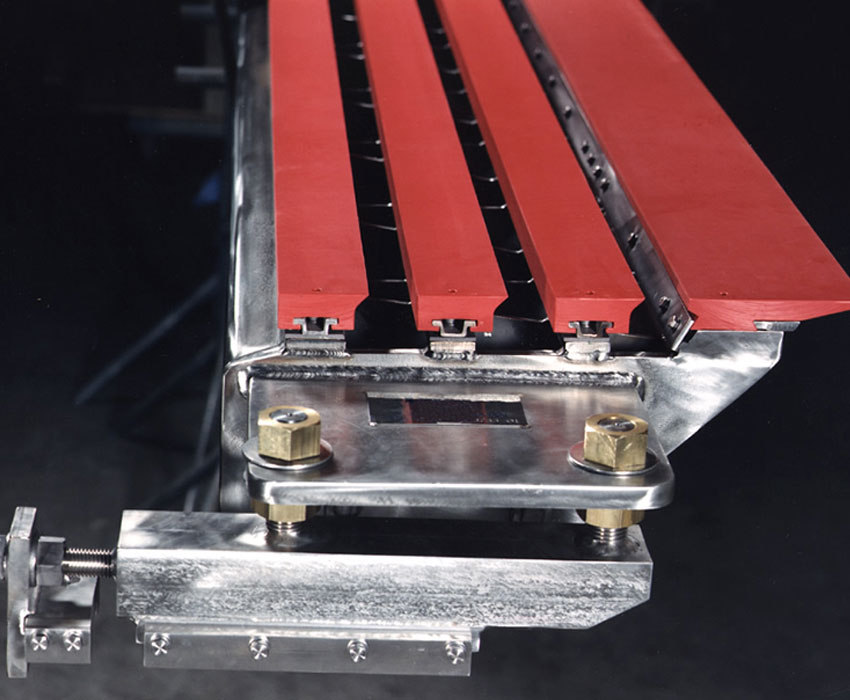

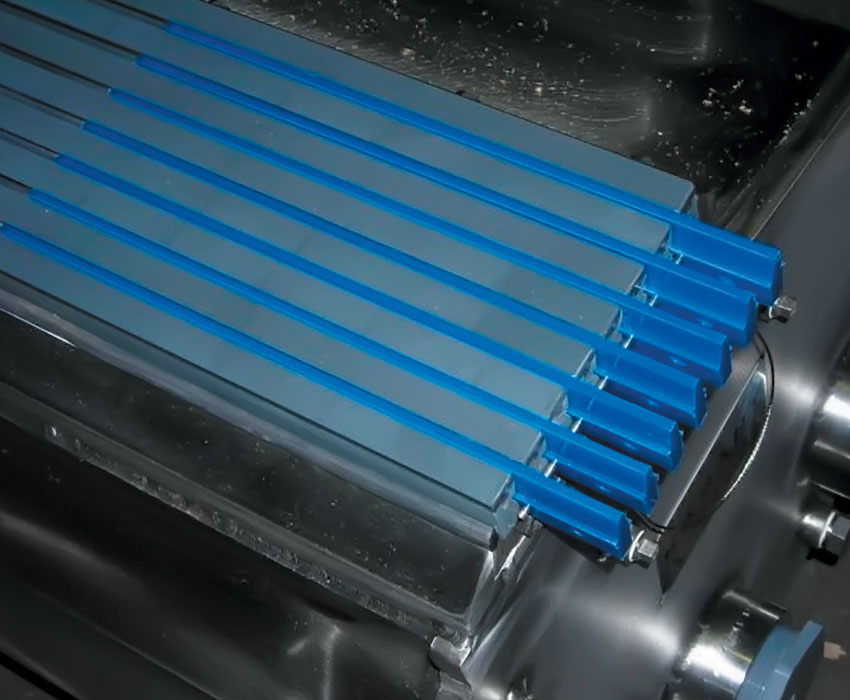

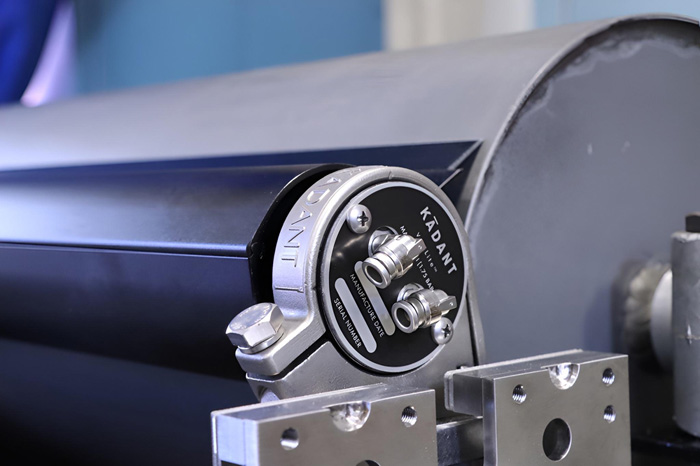

Roll cleaner assemblies are comprised of a roll cleaning blade, blade holder, structural beam, brackets, and bearings along with an option to oscillate. Clean rolls make a difference in metal processing. Our family of roll cleaning systems set the bar for roll cleaning and contaminant removal.

Roll cleaner assemblies are comprised of a roll cleaning blade, blade holder, structural beam, brackets, and bearings along with an option to oscillate. Clean rolls make a difference in metal processing. Our family of roll cleaning systems set the bar for roll cleaning and contaminant removal.

Kadant roll cleaner assemblies are ideal technologies for bridle, pinch, deflector, turn down, steering, tower, tension level, temper rolls, accumulator rolls, and looper rolls to increase quality and reduce sheet defects.

Roll cleaner assemblies such as the VeriLite™ and VeriKleen™ when used with the Ultra C™ roll cleaning blade are designed for metals processing with a compact design, improved safety, and quick blade changes.

Stories and Case Studies

-

Roll Cleaning in Metals Processing: An Interview with Lori Kelly

-

Clean Rolls Make a Difference in Metal Processing Lines

-

VeriLite™ Roll Cleaner Assembly for Metals Industry

-

Ma Steel Runs Cleaner with Kadant VeriLite™ Roll Cleaner Assembly

FAQ

-

How do contaminants like dirt and oil cause defects in metal sheets during processing?

Contaminants can stick to rolls and transfer to metal sheets, causing defects. Cleaning these materials is essential to prevent wasting large metal batches quickly.

-

What are the advantages of using VeriLite roll cleaner assemblies throughout the metals production process?

Installing the VeriLite roll cleaner assemblies on all rolls ensures continuous cleanliness for a defect-free finished product. This improves operator safety by eliminating manual roll cleaning.

-

Are there alternatives to blades for roll cleaning?

The VeriLite roll cleaner assembly offers alternatives such as the EzKleen™ roll polisher. This tool helps maintain roll surface finish, beneficial for worn rolls.

Kadant U.K. Limited and Kadant Solutions manufacture

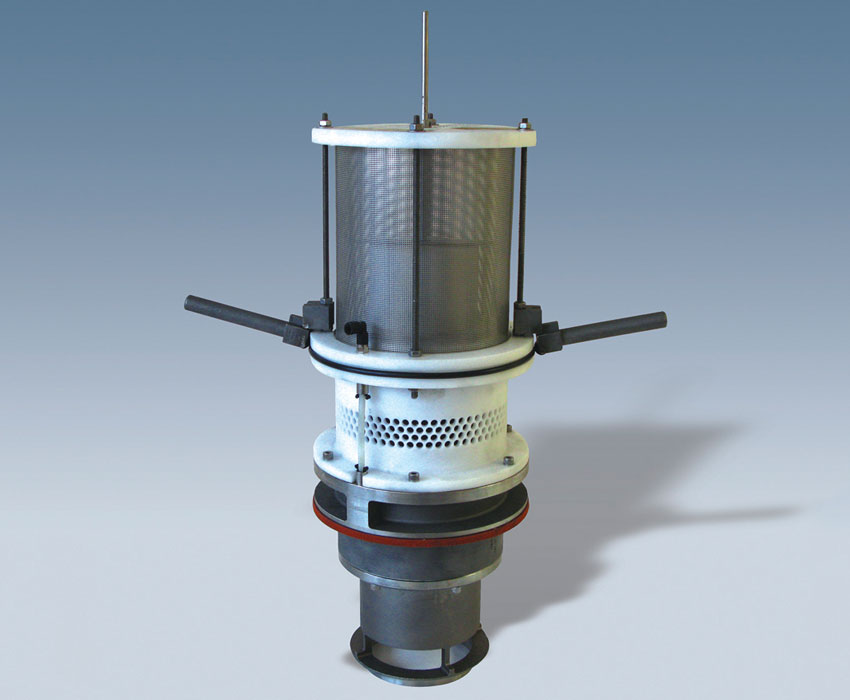

Kadant U.K. Limited and Kadant Solutions manufacture  In food processing a proper filtration system can provide continuous removal of contaminants that may plug up later parts of the process. The

In food processing a proper filtration system can provide continuous removal of contaminants that may plug up later parts of the process. The

Engineered wood producers often encounter challenges with keeping fabrics and press screens clean. Whether using individual caul screens or a continuous press fabric, the voids of the screens must remain clean and clear so that air and other gases can be released out of the material.

Engineered wood producers often encounter challenges with keeping fabrics and press screens clean. Whether using individual caul screens or a continuous press fabric, the voids of the screens must remain clean and clear so that air and other gases can be released out of the material. The

The