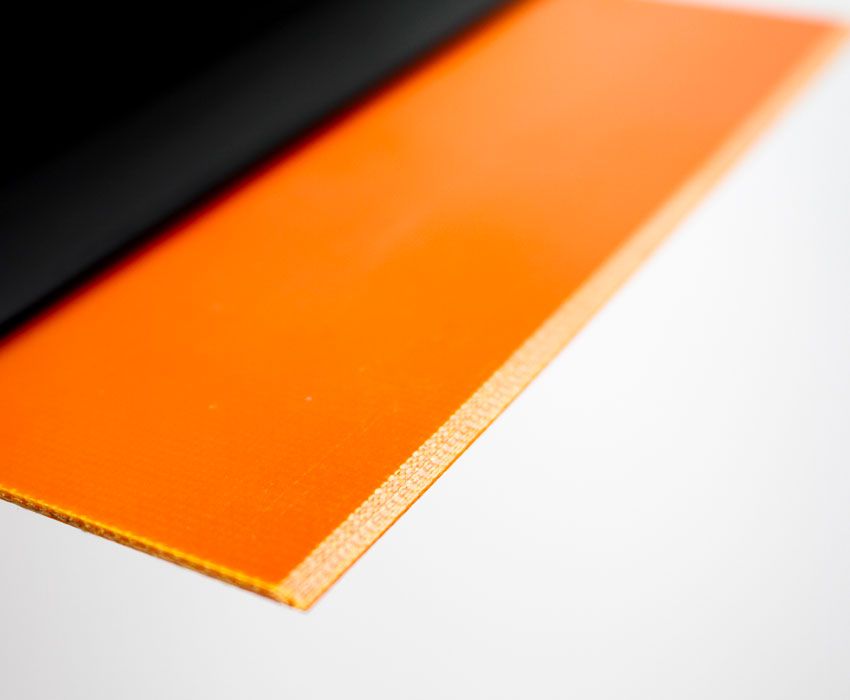

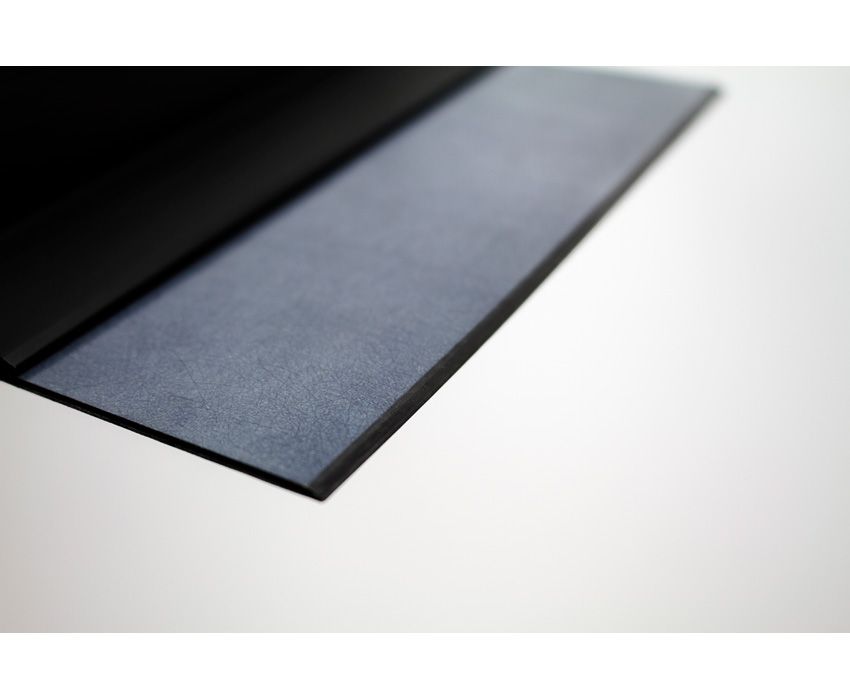

Ultra C™ Doctor Blade

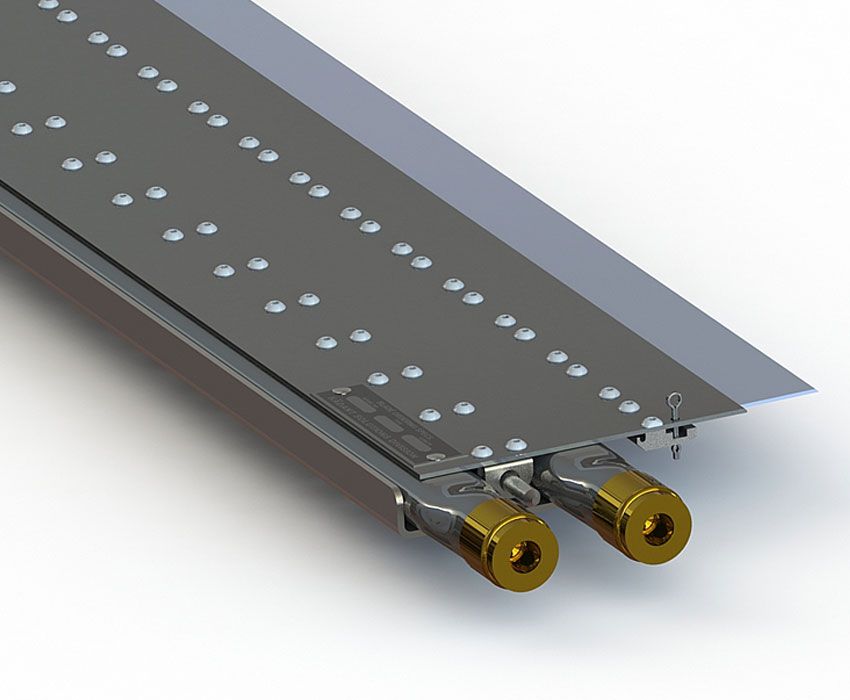

The Ultra C doctor blade is designed for applications that require extended life and a blade to conform to the roll surface at lower pressure for cross-machine flexibility.

The Ultra C doctor blade's unique design is recommended for doctoring ceramic, granite, and composite press rolls, dryers, and calender rolls. It maintains a clean, sharp edge with low pressure and provides excellent chemical resistance, low friction, long blade life, and enhanced machine direction strength for reduced energy consumption and effective sheet shedding.

Features

-

100% carbon fiber construction with unidirectional fiber orientation

-

Proprietary resin composite

-

Maximum temperature: 360°F (180°C)

-

Available thicknesses: 0.055” (1.4 mm) to 0.080” (2.0 mm)

Benefits

-

Conforms easily to roll surface

-

Enhanced MD strength for excellent sheet shedding

-

Low energy consumption

-

Long wear life

FAQ

The Ultra C doctor blade is made of 100% carbon with unidirectional layers, a proprietary resin composite, enhanced machine direction strength, chemical resistance, and low friction. It is highly flexible, efficient, and durable.

Ultra C doctor blades are five times more flexible in the cross machine direction than traditional blades, enabling excellent conformance to roll surfaces. The machine direction strength will allow for lower-pressure cleaning and doctoring while extending equipment life.

The Ultra C doctor blade is a versatile material that can withstand high temperatures up to 360°F, and it also has excellent chemical resistance, especially compared to other composite doctor blade materials. It comes in two different thicknesses, 0.055” and 0.080”, making it appropriate for various applications where its unique properties and extended blade life may be required. Its low energy consumption and efficient design make it a practical choice for maintaining energy-efficient and effective production processes.

Improved machine direction strength removes excess material from the roll surface without damage, resulting in clean, sharp edges and excellent sheet shedding capabilities for high-quality production output.