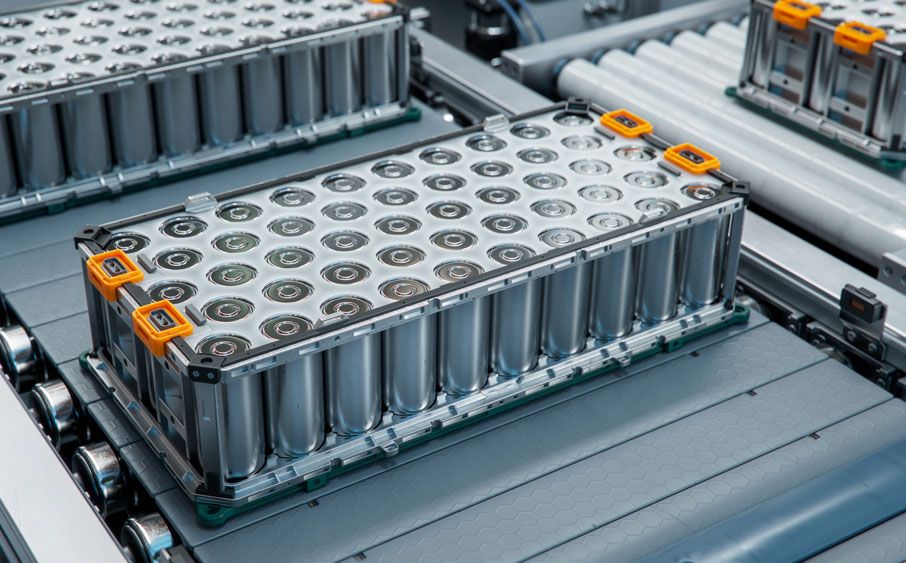

Lithium- Ion Battery Processing

Kadant helps lithium-ion battery manufacturers improve uptime and productivity with our innovative roll cleaning solutions. Our VeriLite™ roll cleaning assembly is a compact yet robust system that removes debris from calender rolls continuously, preventing defects in the finished product and damage to the roll itself. Incorporating the X-Tek™ roll cleaning blade with the VeriLite roll cleaner assembly results in less downtime and waster materials, and a safer production environment for operators.

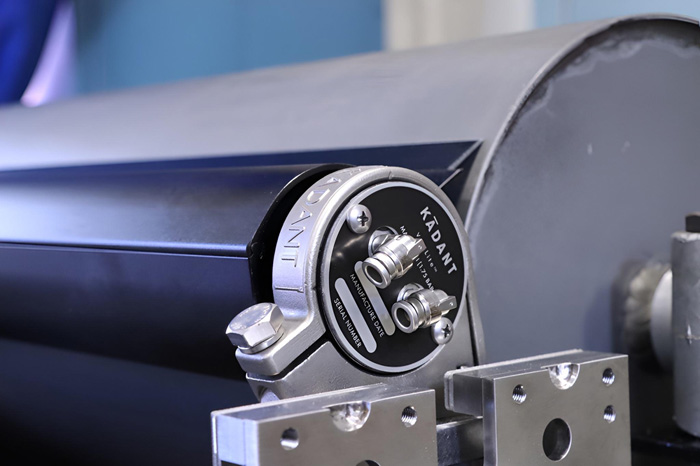

Roll Cleaner Assemblies

Roll cleaner assemblies are comprised of a roll cleaning blade, blade holder, structural beam, brackets, and bearings along with an option to oscillate. Clean rolls make a difference in lithium-ion battery production. Our family of roll cleaning systems set the bar for roll cleaning and contaminant removal.

are comprised of a roll cleaning blade, blade holder, structural beam, brackets, and bearings along with an option to oscillate. Clean rolls make a difference in lithium-ion battery production. Our family of roll cleaning systems set the bar for roll cleaning and contaminant removal.

The VeriLite roll cleaner assembly is a versatile and effective solution for removing debris from calender rolls in the lithium-ion battery production process. It is uniquely suited for the of battery processing environment, and its continuous cleaning action helps to reduce downtime and expensive machine repairs. The VeriLite roll cleaner assembly is easy to use and maintain, making it a cost-effective investment for any battery manufacturer.

The X-Tek roll cleaning blade is suitable for high-temperature applications with highly polished roll surfaces like those used in lithium-ion battery production. The blade includes polymeric and carbon fibers to provide effective cleaning while ensuring there is no damage to a roll surface.

FAQ

Yes. There are roll cleaning blade materials available with high temperature resins capable of being used in temperatures as high as 570°F (299°C).

Choosing the right type of fibers and resin is key when selecting the roll cleaning blade. Usually, carbon fiber is used as a tough, wear resistant material but will be gentle and ensure that the roll surface roughness is maintained. Additionally, there are a series of roll conditioning pads available with the EzKleen™ V roll cleaner assembly that can further enhance roll conditioning.

Yes. Oscillation can improve the roll cleaning process. The movement of the blade tip provides a secondary cleaning action and ensures that debris does not embed into the blade tip, which could groove or score the roll surface.