Fiberglass Mat Processing

Kadant products play a pivotal role in the fiberglass mat production industry, particularly in wire belt cleaning and roll cleaner assemblies. New technologies in cleaning systems align with our dedication to innovation, enhancing process efficiency and safety. These advancements also reduce energy costs and support companies in achieving greater sustainability in their operations.

Wire Belt Cleaning

The M-clean™ system is designed to effectively remove contaminants from wire belts, ensuring top-quality material production. It's tailored for use in the forming, saturating, and drying stages of fiberglass mat production. By addressing and eliminating contaminants on wire belts, it plays a pivotal role in maintaining the quality of fiberglass mats while minimizing production interruptions. This system reflects our dedication to improving production efficiency and mat quality.

The M-clean™ system is designed to effectively remove contaminants from wire belts, ensuring top-quality material production. It's tailored for use in the forming, saturating, and drying stages of fiberglass mat production. By addressing and eliminating contaminants on wire belts, it plays a pivotal role in maintaining the quality of fiberglass mats while minimizing production interruptions. This system reflects our dedication to improving production efficiency and mat quality.

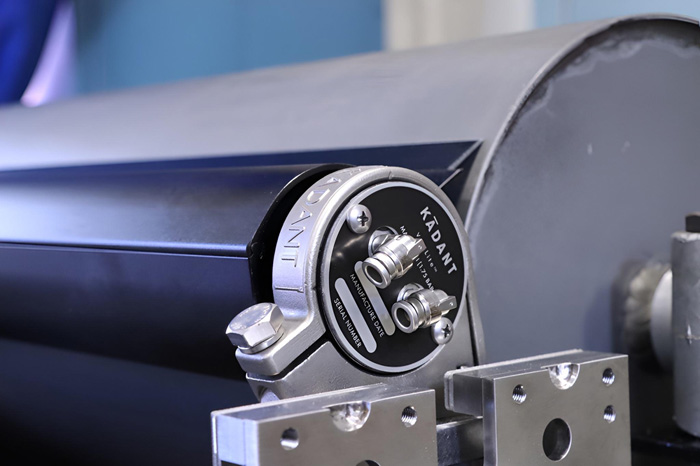

Roll Cleaner Assemblies

In fiberglass mat production, roll cleaner assemblies, specifically the VeriLite™ roll cleaner assembly has the crucial task of keeping the production rolls clean. This attention to cleanliness is crucial because any contaminants on the rolls can lead to defects in the final fiberglass mats. The roll cleaner assembly’s efficiency simplifies the process and directly contributes to the overall quality of fiberglass mats.

In fiberglass mat production, roll cleaner assemblies, specifically the VeriLite™ roll cleaner assembly has the crucial task of keeping the production rolls clean. This attention to cleanliness is crucial because any contaminants on the rolls can lead to defects in the final fiberglass mats. The roll cleaner assembly’s efficiency simplifies the process and directly contributes to the overall quality of fiberglass mats.

FAQ

It operates with reduced water consumption, lessening the environmental impact of mat production.

Yes, it's designed to clean wire belts throughout all stages of fiberglass mat production including forming wire, saturator wire, and dryer wire.

Roll cleaning is crucial for removing accumulations and buildup from roll surfaces, which is essential for smooth production and the creation of high-quality mats.

While the M-Clean system cleans wire belts, roll cleaning maintains roll surface cleanliness, together enhancing overall production quality and efficiency.