Roofing Shingles

Kadant products are used in the manufacturing processes of finished roll roofing and roofing shingle products. Kadant’s latest technologies in roll cleaning systems increase process efficiency, reduce energy costs, and enhance productivity. Roll cleaner assemblies prevent debris buildup on production rolls during production, ensuring smooth operation and reducing downtime.

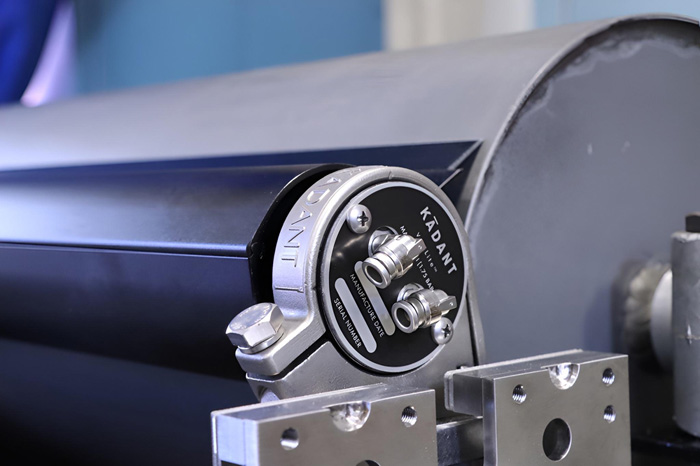

Roll Cleaner Assemblies

In roofing material manufacturing, the VeriLite™ and VeriKleen™ roll cleaner assemblies keep production rolls clean. The VeriLite roll cleaner assembly operates pneumatically for harsh environments, while the VeriKleen roll cleaner assembly uses a lever mechanism for durability. Both are suitable for wet, dry, and high-temperature environments, featuring lightweight construction, compact designs, and quick blade changes. This cleanliness prevents defects, improves efficiency, and reduces downtime.

Stories and Case Studies

FAQ

By reducing downtime and improving cleaning processes, Kadant’s products enhance overall operational efficiency.

Kadant products enhance safety by automating cleaning processes, reducing the need for manual cleaning, and minimizing worker exposure to hazards.

Roll cleaning technology ensures that production rolls remain clean, preventing defects, and enhancing the durability of the finished roofing shingles.