Multiple-Barrel Pressure Filter

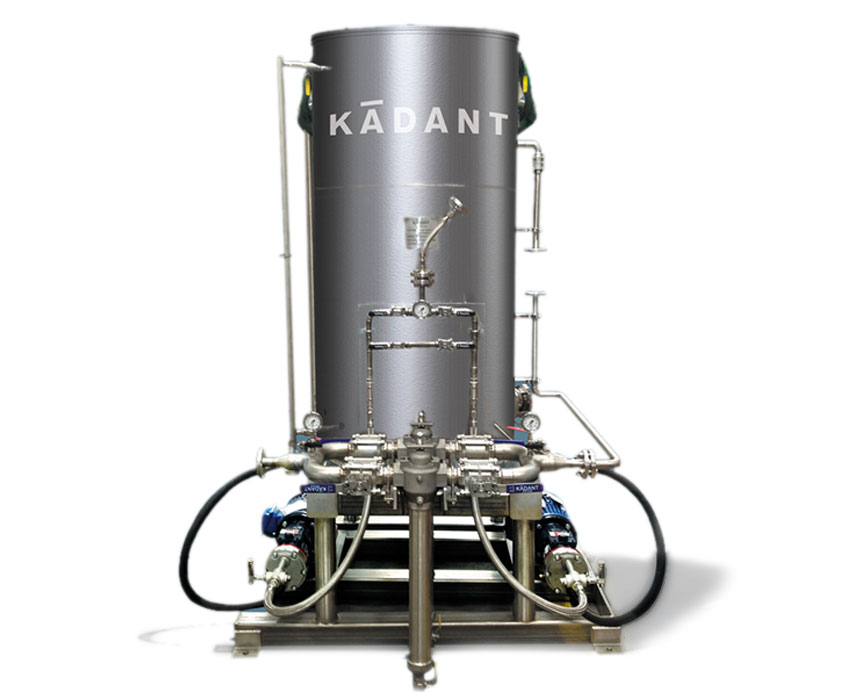

ErGo™ Filtration System

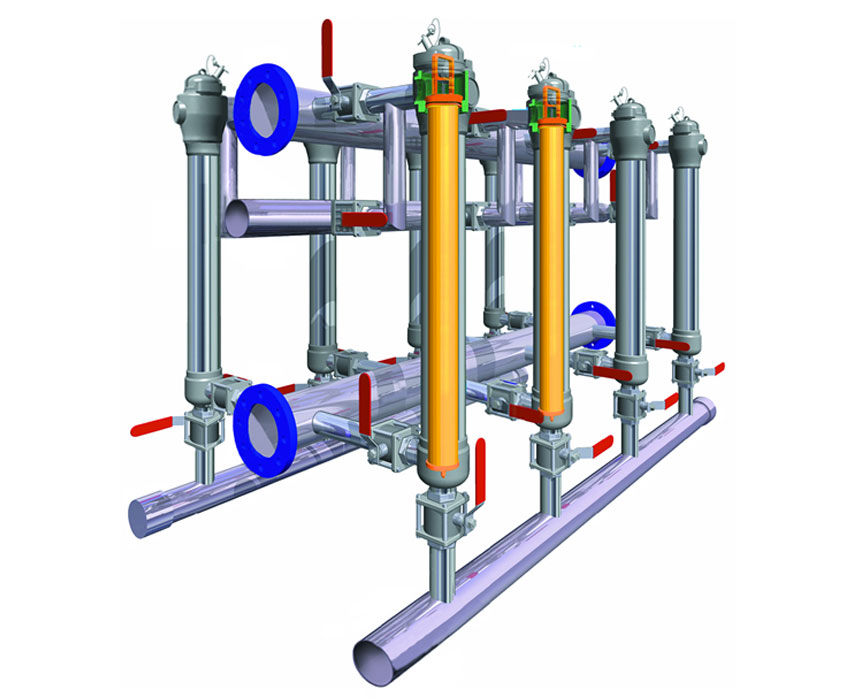

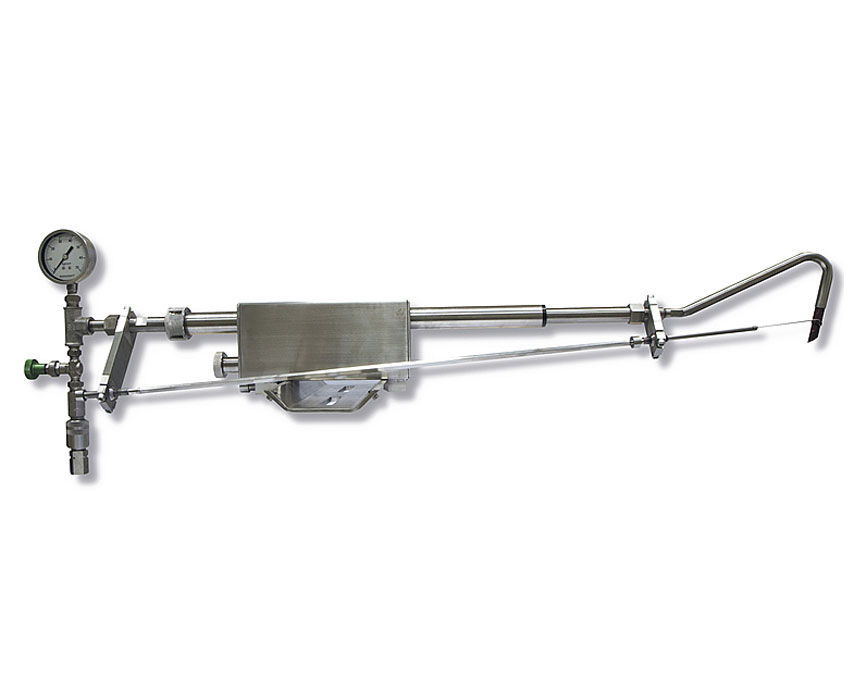

MegaFlo™ Backwash System

File Downloads

Reduced municipal treatment plant charges

Improved machine cleanliness

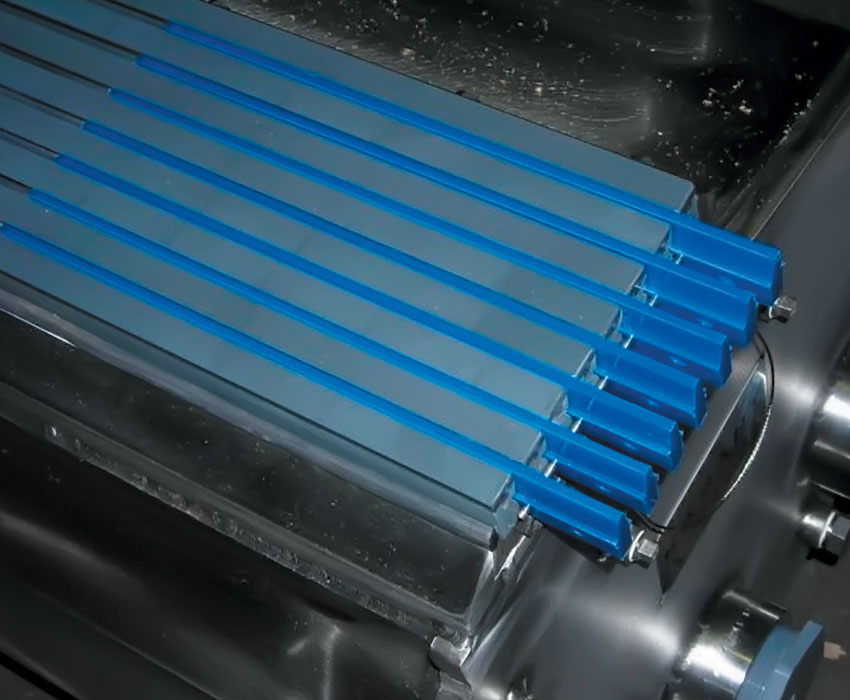

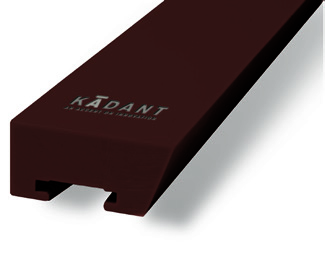

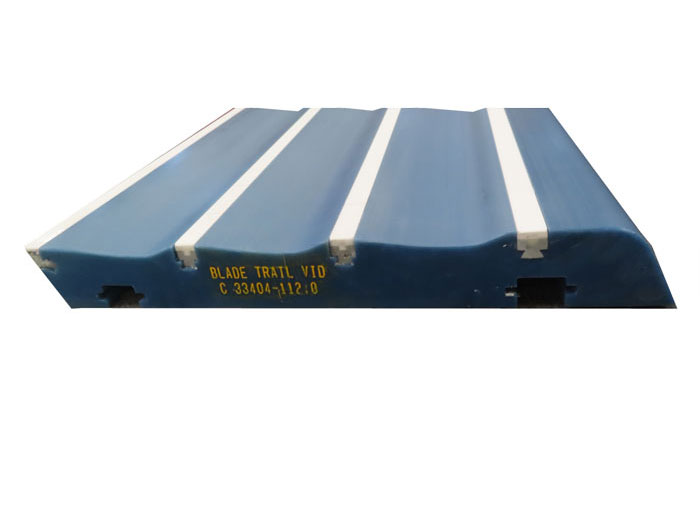

Wear surfaces in paper forming are sometimes referred to as foil blades, forming blades, or drainage elements provide the support on the drainage structures in the forming and pressing sections of a paper machine.

Wear surfaces are in direct contact with paper machine clothing and can have a profound impact on overall production and paper quality. There are three families of wear surfaces: polyethylene, ceramic, and hybrid.

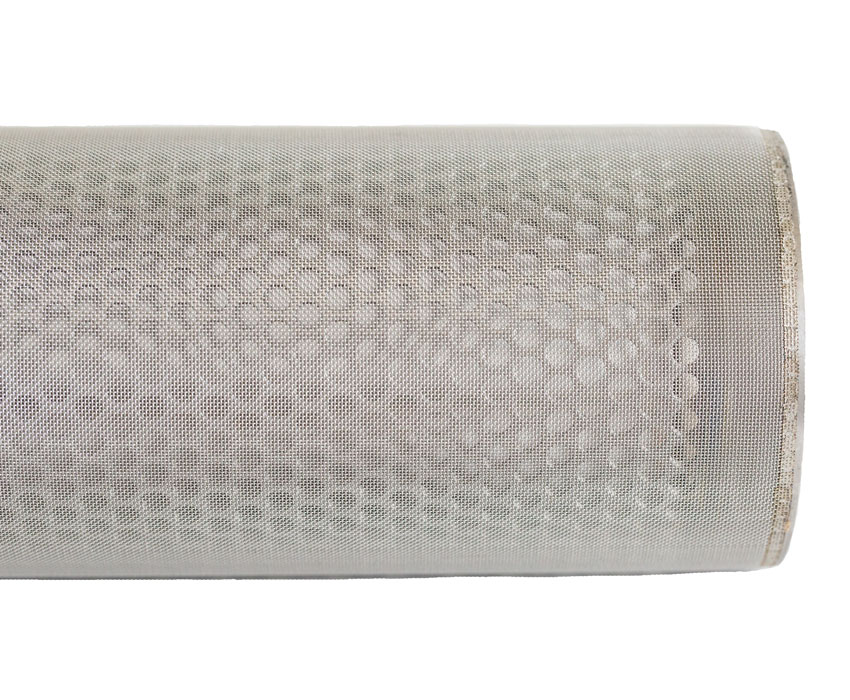

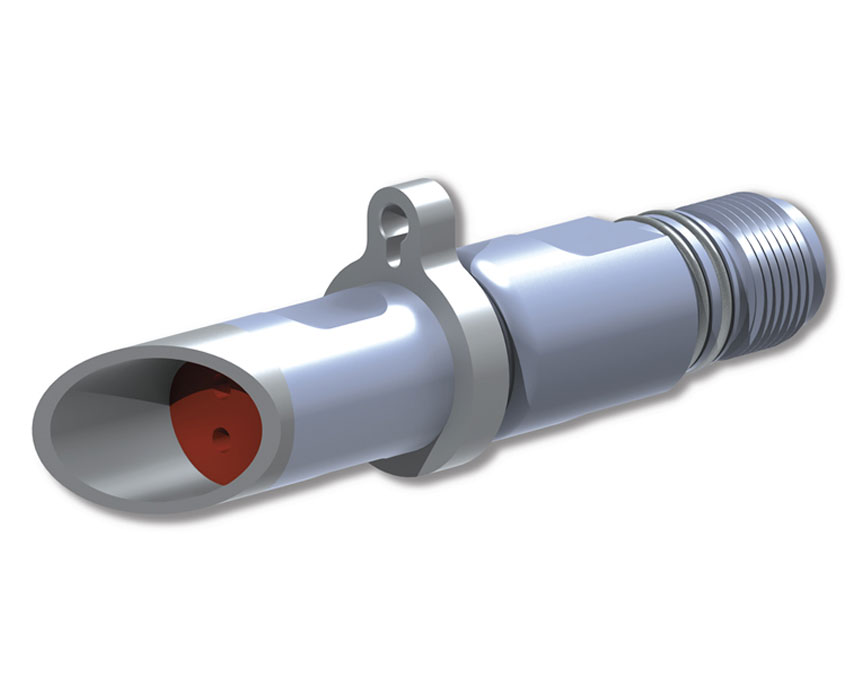

Our simple filter design of in-line filters can be provided in either a single or duplex arrangement. A single in-line filter is normally used in applications where the flow can be interrupted, or the filter can be bypassed when the filter element is serviced. Duo filters are typically used when continuous filtration is required.

It is most commonly applied on machines operating with sizable amounts of secondary fiber in the process. Generally applied as a forming-fabric cleaning and conditioning component, our fabric cleaning brush is used in both dryer fabric and nonwoven machine applications.