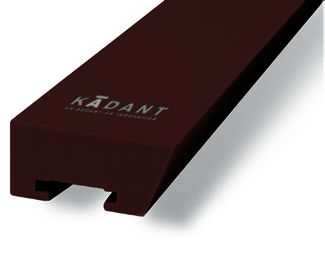

Durwear™ Polyethylene Wear Surfaces

Durwear polyethylene wear surfaces are in direct contact with a paper machine’s clothing. Each Durwear grade is formulated to give a distinct set of characteristics. All are manufactured to ensure critical blending, extrusion, and machining standards are continuously monitored.

Durwear HTb

Durwear HTb is specially formulated with an antioxidant and a proprietary lubricant. The resulting blend has significantly greater wear resistance than standard polyethylene under high temperatures and oxidizing conditions.

Durwear A+

Developed for long life and high dimensional stability under the most demanding forming and pressing conditions, Durwear A+ combines the properties of standard Durwear HTb along with added abrasion resistance to last twice as long as standard poly.

Durwear XW

For several mills, Durwear XW has tripled and quadrupled wear life in wet end applications with no adverse effects on fabric life. This highly engineered polyethylene is formulated for maximum wear resistance and stability at high operating temperatures and sets the performance standard for wear surfaces.

Features

-

Premium UHMW polyethylene

-

High wear-resistant additives

-

Formulated specifically for paper machine applications

-

Resistant to chemical and temperature extremes

Benefits

-

Long performance life

-

Improved runnability in forming and press sections

-

Improved dewatering

-

Optimizes fabric life

FAQ

The answer varies depending on the process, chemicals being used, and the environment. For example, fillers may be in the system such as contaminants used in recycling. These contaminants can cause issues with the process which influences the life of the wear surface. We take a holistic approach to understanding your process to give you a better approximation of the products life.