Ultrawear™ Ceramic Wear Surfaces

Paper machines demand high-quality durable ceramic wear surfaces also known as foil blades, forming blades, or drainage elements to meet the everyday challenges of production. Ceramic wear surfaces provide the support on the drainage structures in the forming and pressing sections of a paper machine.

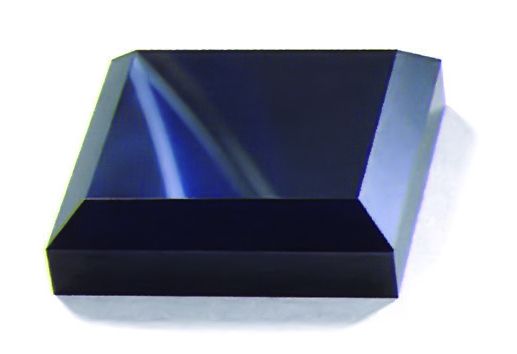

Alumina Ultrawear AL Ceramic Wear Surfaces

Advantages: Low cost; good wear and corrosion resistance; moderate machine drag.

Applications: Fourdrinier, except on flatboxes when calcium carbonate is used.

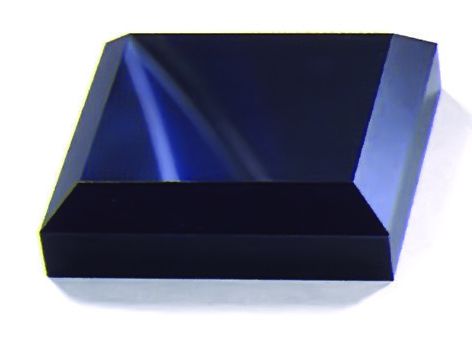

Silicon Nitride Ultrawear SN Ceramic Wear Surfaces

Advantages: High thermal shock resistance; low fabric wear, low drive load; best all-around combination of wear, chip, and corrosion resistance.

Applications: High stress applications, like suction boxes and felt strips; all applications where calcium carbonate is used.

Silicon Carbide Ultrawear SC Ceramic Wear Surfaces

Advantages: The hardest, most wear resistant ceramic; moderately high thermal shock resistance.

Applications: All applications where severe ceramic wear is present.

Features

-

Propriety construction

-

OEM replacements designs

-

Highest quality ceramic materials

Benefits

-

Improved fabric life

-

Lower drag load

-

Long ceramic life

File Downloads

FAQ

The answer varies depending on the process, chemicals being used, and the environment. For example, fillers may be in the system such as contaminants used in recycling. These contaminants can cause issues with the process which influences the life of the wear surface. We take a holistic approach to understanding your process to give you a better approximation of the products life.