Field Service

Kadant Solutions takes field service to a new level. Our expert team of U.S. based field service technicians are committed to providing your mill with a safe, quality, timely, and efficient experience whether onsite or remote. Let the Kadant Solutions field service team plan, implement, manage, and develop customized maintenance strategies for your facility.

Technical Services

Machine and Equipment Audits

A true understanding of machine and equipment performance is the key to a safe, high-quality, and efficient process. Our team performs comprehensive machine and equipment audits including digital machine mapping. The result is a detailed service assessment with feedback, recommendations, and project justification.

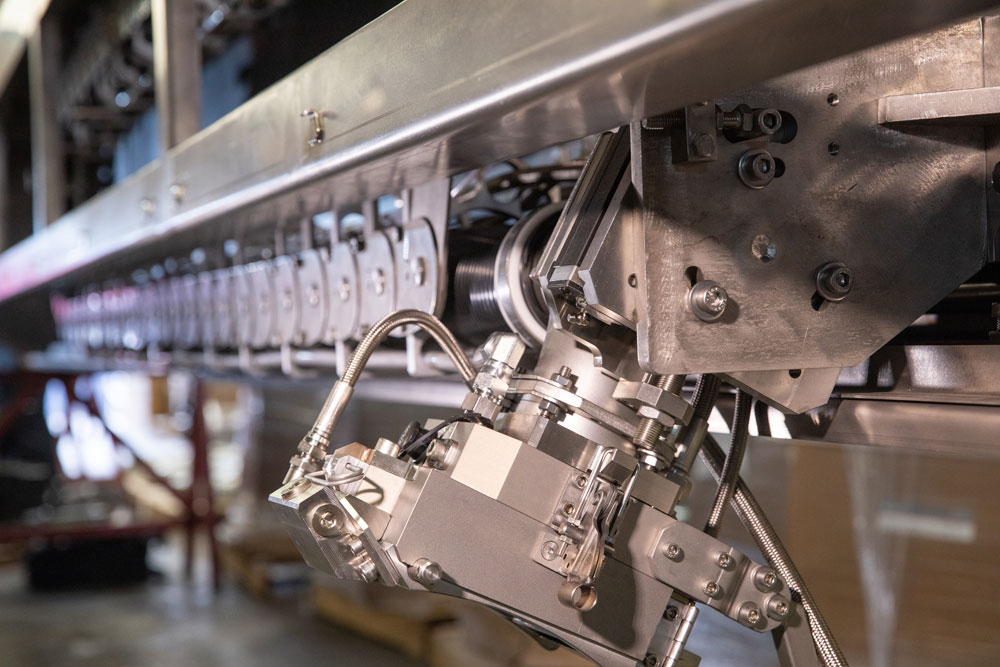

Preventative Maintenance and Repairs

![]()

Properly maintaining and repairing equipment improves safety, machine uptime, quality, and return on investment. Collaborating with your team, we customize preventative maintenance and repair contracts. Our team will recommend, perform, and manage preventative maintenance programs and repairs using only Kadant Solutions Genuine Parts.

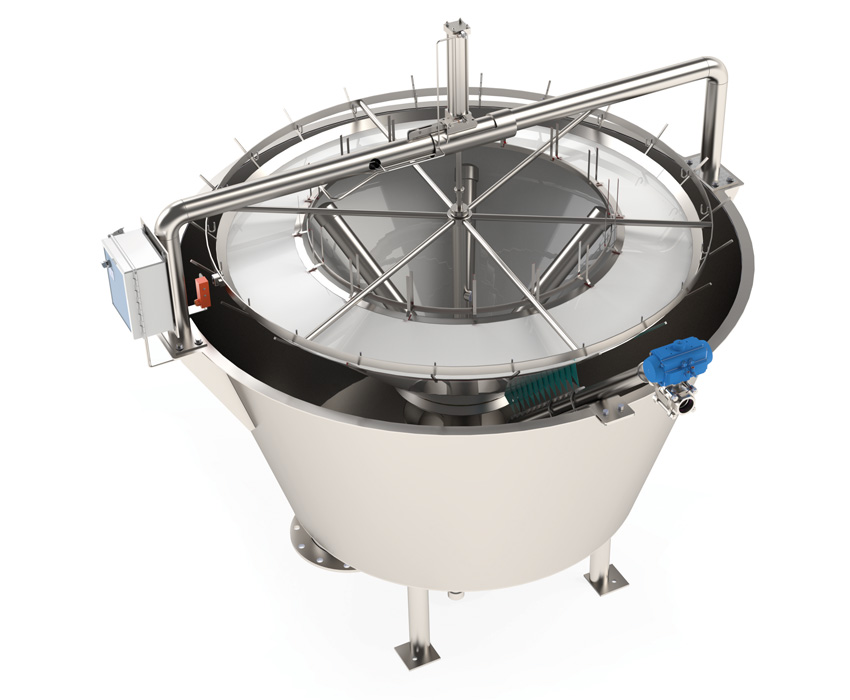

Yankee Doctor Services

Yankee doctors operating at maximum efficiency is crucial to the success of any tissue operation. The field service technician will inspect all mechanical components including mounting brackets, bearings, journals, doctor structure, blade holder, levers, air cylinders, oscillation, and other equipment. Also, the blade angle will be adjusted to your specific application and the blade holder profile will be checked, and necessary adjustments made to ensure a proper blade-to-surface fit. A full report including service details, before and after profile diagrams, and recommendations for improved performance will be provided after each service.

Equipment Installation Supervision

Onsite supervision and technical support for capital equipment installations will ensure your investment in new equipment is installed correctly and meets the needs and expectations of your mill.

Turnkey Services

Our turnkey services offer tailored mechanical maintenance and project execution, particularly for mills facing resource constraints and manpower shortages. By supervising every aspect directly at customer sites, we assume full ownership of the work, ensuring it's completed to KSD standards—accurately, on time, and properly. This comprehensive solution spans from routine upkeep to executing major capital ventures, all designed to boost operational efficiency and dependability. Our methodical process, from the initial planning to the final handover, guarantees precision and a commitment to excellence, aligning with customer expectations for impactful outcomes.

Training

Education and training are the foundation for maintaining a safe environment, high-quality product, and efficient performance of mill equipment. Our field service team can provide custom, onsite, remote, and equipment-specific training.

E-Services

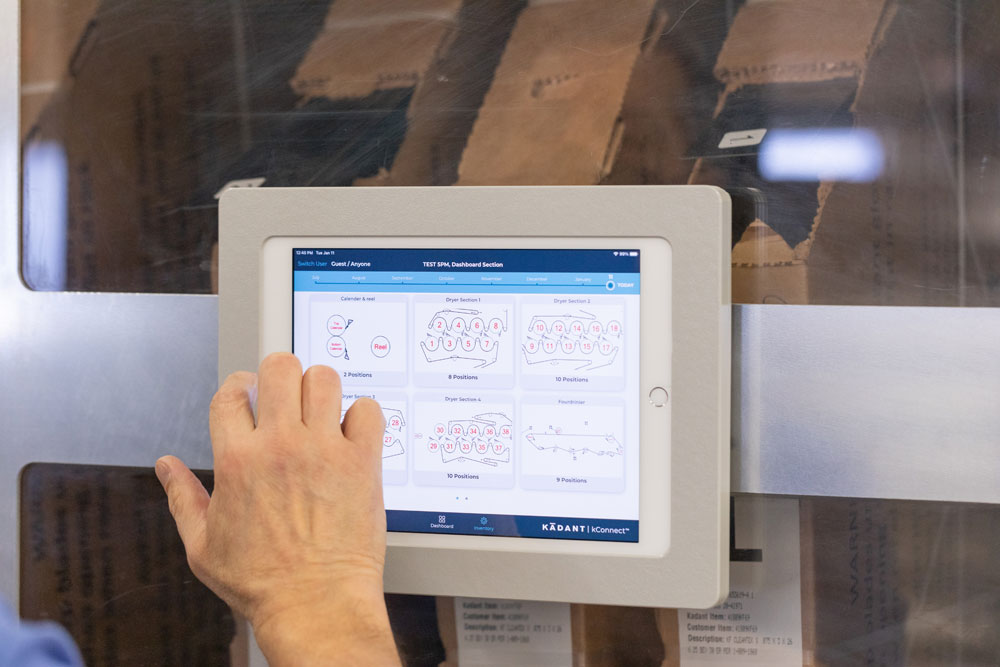

kConnect™ series

The kConnect series of products and services offer intelligent monitoring of equipment. This smart-connected technology provides insights for preventative maintenance plans and predictive monitoring.

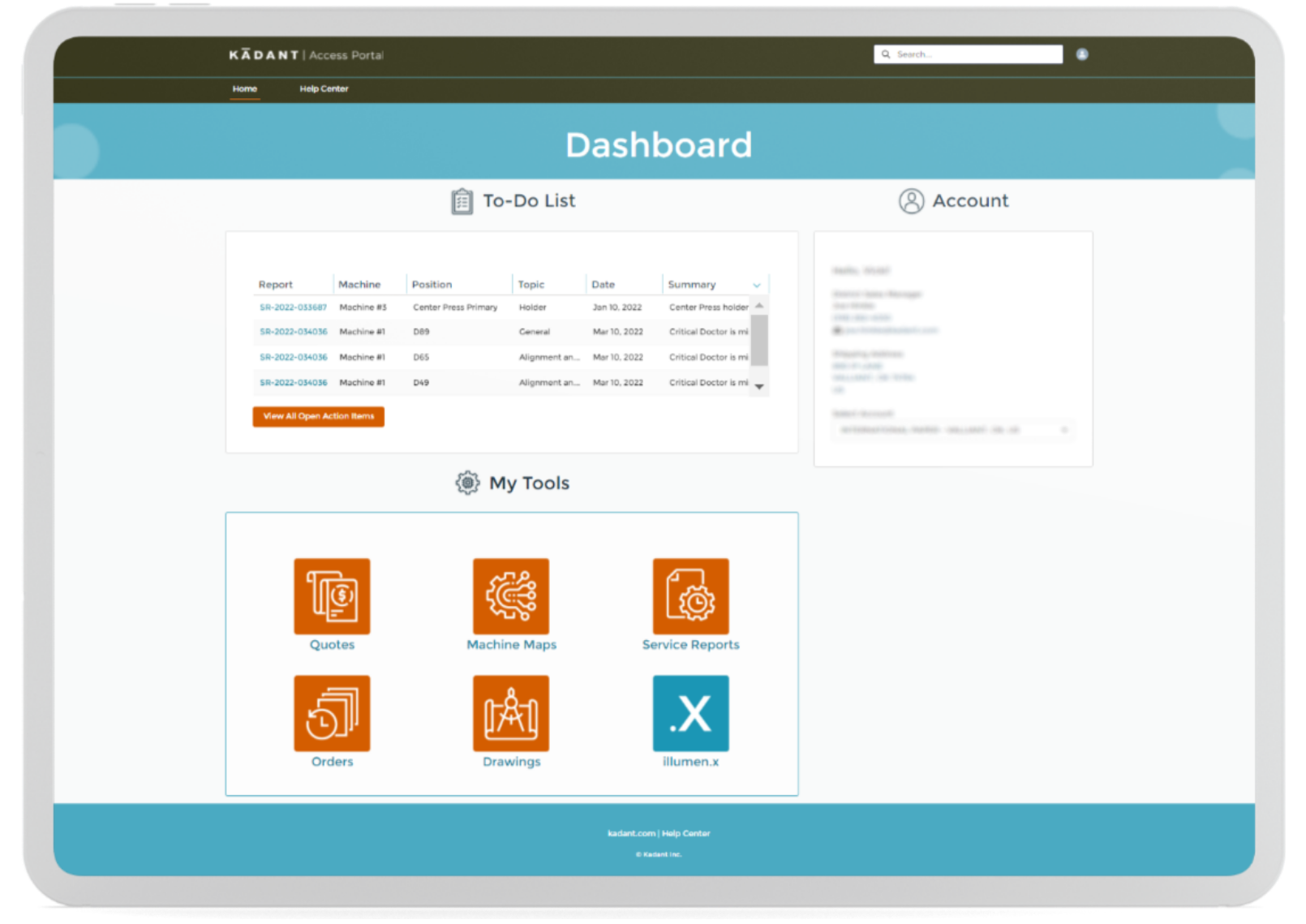

Kadant Access Portal™ (KAP)

The Kadant Access Portal provides access to a comprehensive suite of process management tools. Keep track of action items, quotes, service reports, drawings, and orders for machines throughout your facilities. View maps of machinery, as well as details regarding the grade and any pertinent status information.

Meet Our Team

Our field service team is strategically located throughout the U.S. to ensure nationwide coverage with quick, reliable availability when you need it most.

-

Casey McDaniel

-

Cody Cranfill

-

Dave Chounard

-

Joe Scalzo

-

Alex Simmons

-

Jake Mura

-

Jacob Kelly