How Can Roll Cleaning Improve Safety in the Carbon Fiber Industry?

You’ve seen these signs before. Most facilities rely on them to remind operators of the ever-present dangers of their operations.

So how do you safely prevent fiber wraps and fuzz build-up during carbon fiber production from leading to oven fires and production stoppages?

If duct tape and a brush are your solution, you are not alone. Production facilities have been developing homemade tools to keep machines up and running for decades. This may be one way of minimizing the negative impact that fuzz and fiber breaks can have on continuous processes because it allows your operators to intervene from a safer distance. However, it too can cause safety issues such as pieces falling off, and inconsistency during cleaning, and is dependent on operators identifying and correcting problems before they disrupt operations.

If duct tape and a brush are your solution, you are not alone. Production facilities have been developing homemade tools to keep machines up and running for decades. This may be one way of minimizing the negative impact that fuzz and fiber breaks can have on continuous processes because it allows your operators to intervene from a safer distance. However, it too can cause safety issues such as pieces falling off, and inconsistency during cleaning, and is dependent on operators identifying and correcting problems before they disrupt operations.

How about a solution to the homemade tool problem?

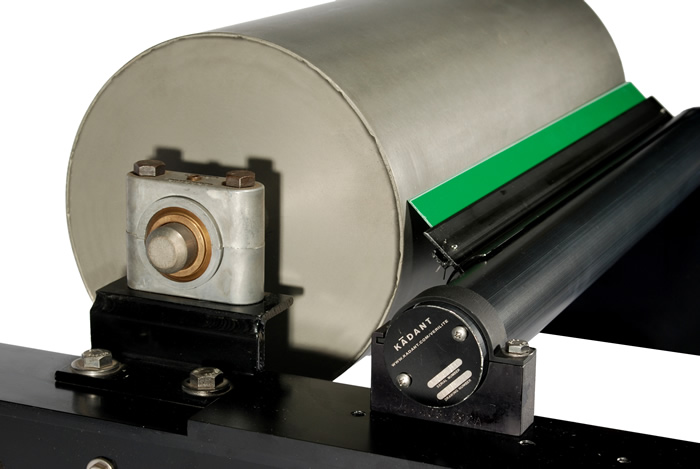

The VeriLite™ roll cleaner assembly was developed to address the homemade tool challenge. It is designed specifically to fit the narrow clearance in syntheticfiber processing rolls while providing roll cleaning and web management. It is like having an operator stationed at each roll without violating safety boundaries.

Once the VeriLite roll cleaner assembly is installed:

1. Broken fibers are prevented from wrapping rolls without operator intervention.

2. Fuzz build-up can be safely removed during operation before being carried into an oven.

Download this VeriLite roll cleaner assembly case study from a carbon fiber manufacturer.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.