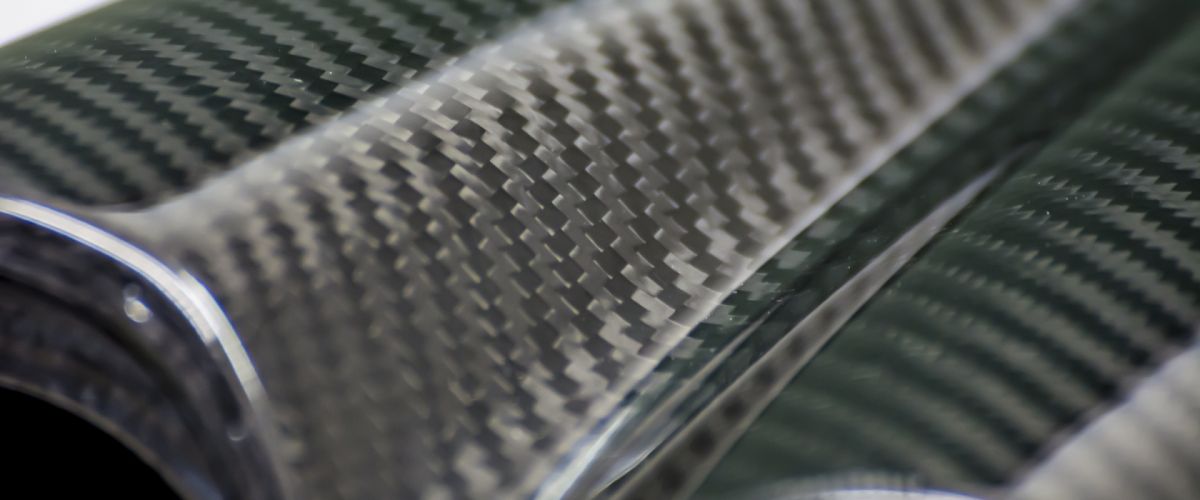

How Can Roll Cleaning Help the Carbon Fiber Industry?

Fuzz and fiber breaks limit a facility's production yield when they cause unplanned stoppages and can even be a serious safety concern when fire ignites inside the ovens. Because of these issues, operator intervention is required to keep a production line running. While necessary, operator intervention is rarely the safest or most efficient work practice.

Is it possible to effectively manage fiber tows, minimize unplanned stoppages without constant operator intervention, and increase production line yield? The answer is YES! It is possible and one method of achieving this is with proper roll cleaning.

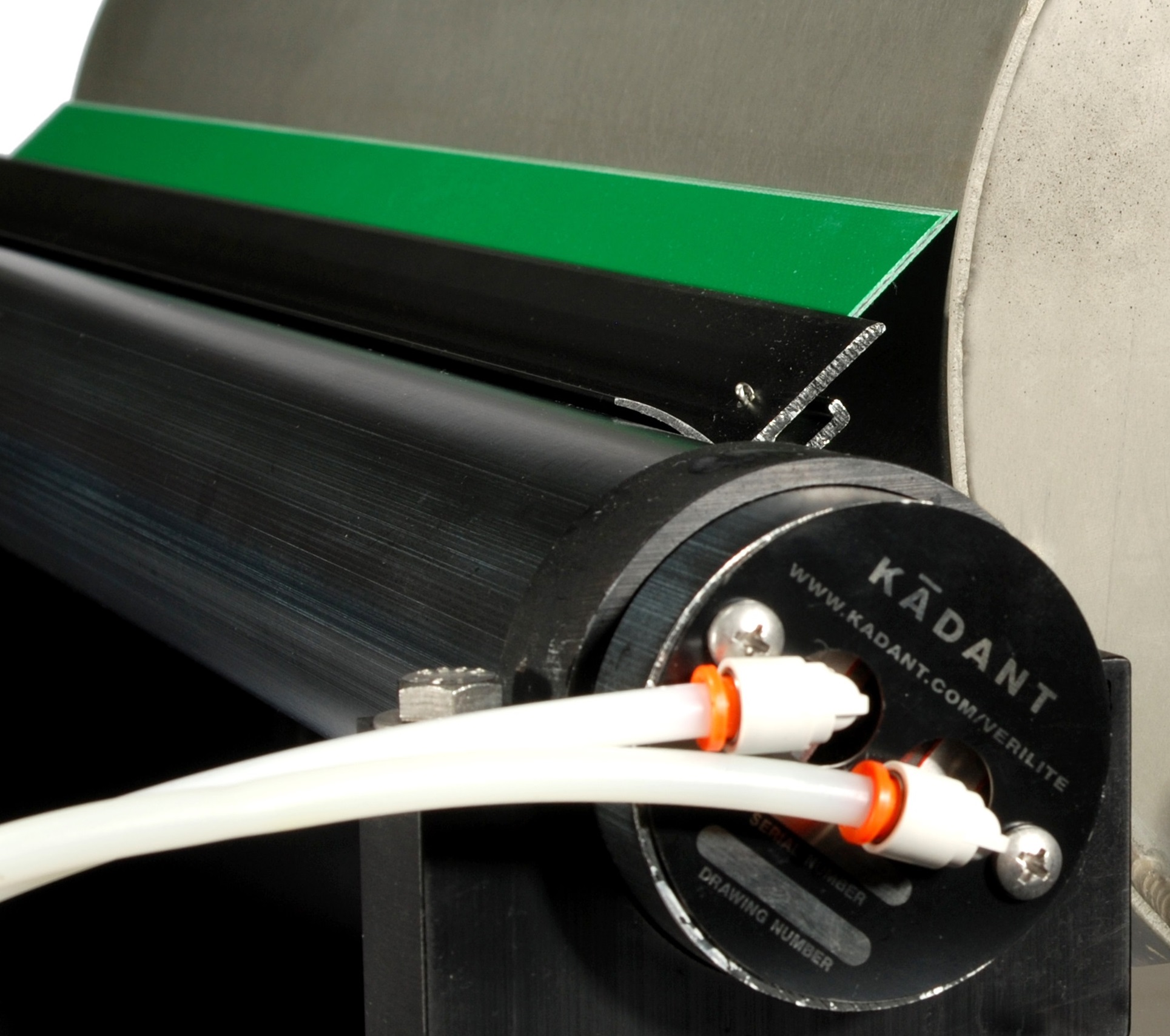

Kadant’s VeriLite™ roll cleaner assembly is designed specifically to fit the narrow clearances present in synthetic fiber processing while providing roll cleaning and web management. The VeriLite roll cleaner assembly improves oxidation oven performance by offering:

Kadant’s VeriLite™ roll cleaner assembly is designed specifically to fit the narrow clearances present in synthetic fiber processing while providing roll cleaning and web management. The VeriLite roll cleaner assembly improves oxidation oven performance by offering:

- High line yield from continuous roll cleaning

- Reduction in broken fiber from wrapping rolls and reintroducing it to the fiber tow

- Operators to safely remove fuzz build-up while the line is running

- Lower roll drag than brushes, pads, or other cleaners

- Reduced maintenance downtime for blade changes

- Minimal maintenance requirements

To meet the anticipated future demand for carbon fiber, manufacturers will have to implement process improvements that increase yield. Future fiber-related process interruptions will only be compounded by wider and faster machines and by the variety of lower-cost precursor materials. Without increasing the width or speed of a production line, the above advantage found with the VeriLite roll cleaner assemblyleads to greater yield by reducing unplanned stoppages and shortening maintenance periods.

Download this VeriLite roll cleaner assembly casestudy from a carbon fiber manufacturer.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.