Kadant U.K. Limited

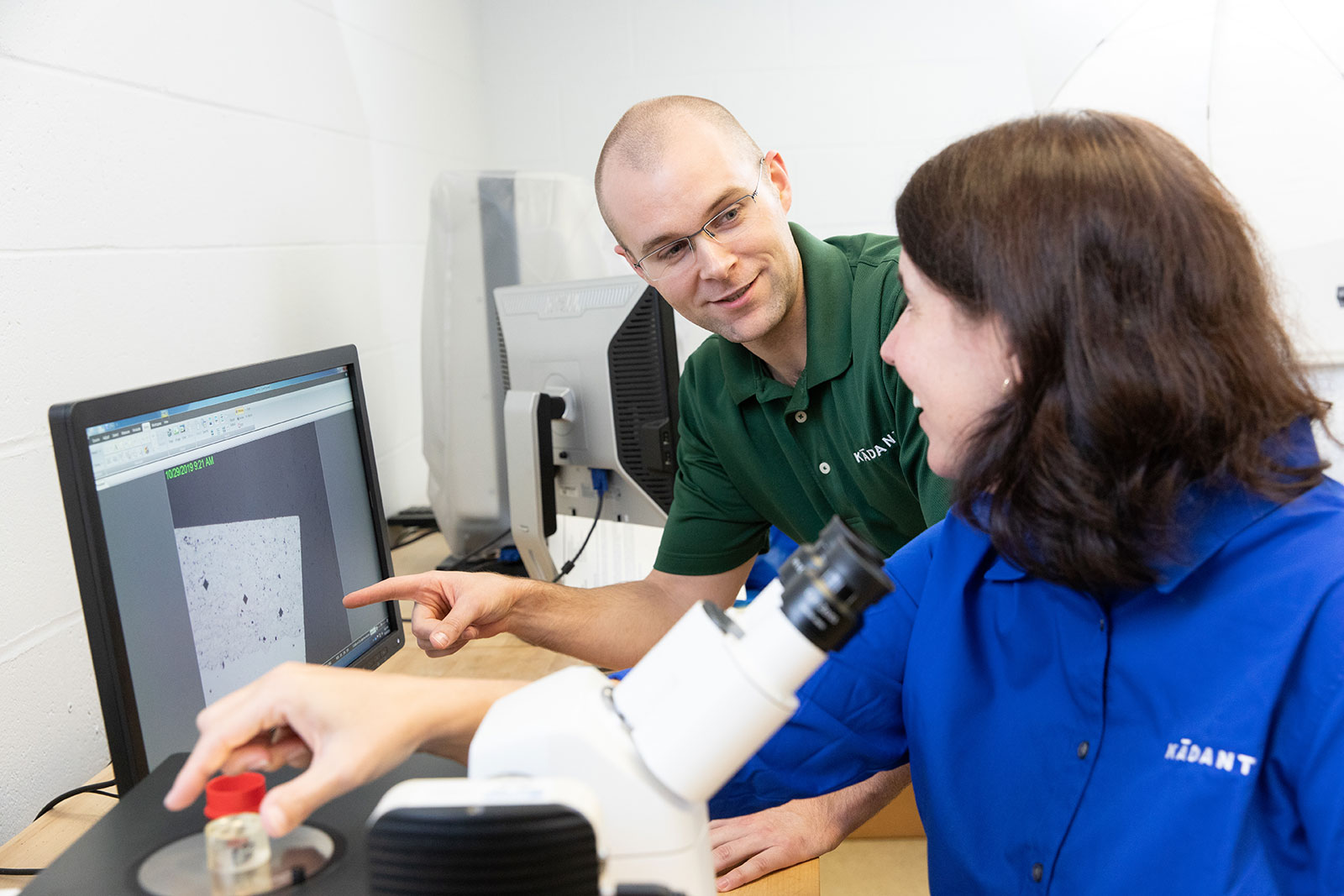

Kadant U.K. Limited is a Center of Excellence amongst several Kadant businesses for doctor blade development.

Areas of expertise

-

Improving process efficiency

-

Increasing up time

-

Optimizing runnability

-

Cleaning moving surfaces (rolls, belts, conveyors, etc.) by scraping, doctoring, wiping, or showering

-

Process water recovery and reuse

-

Process steam systems

Kadant U.K. Accreditations

SafeContractor

As a SafeContractor member, Kadant U.K. has been audited and accredited for its health and safety practices by Alcumus, a leading provider of risk management solutions. Kadant’s sustainability performance has also been verified by Alcumus, earning the trust of hundreds of customers who value environmental and social responsibility.

Kadant U.K. shows its dedication to health, safety, and sustainability by being a SafeContractor member with an accredited status from Alcumus, a recognised authority in risk management. Alcumus has also verified Kadant’s sustainability credentials as a preferred partner for hundreds of customers who seek high standards of environmental and social impact.

HACCP International

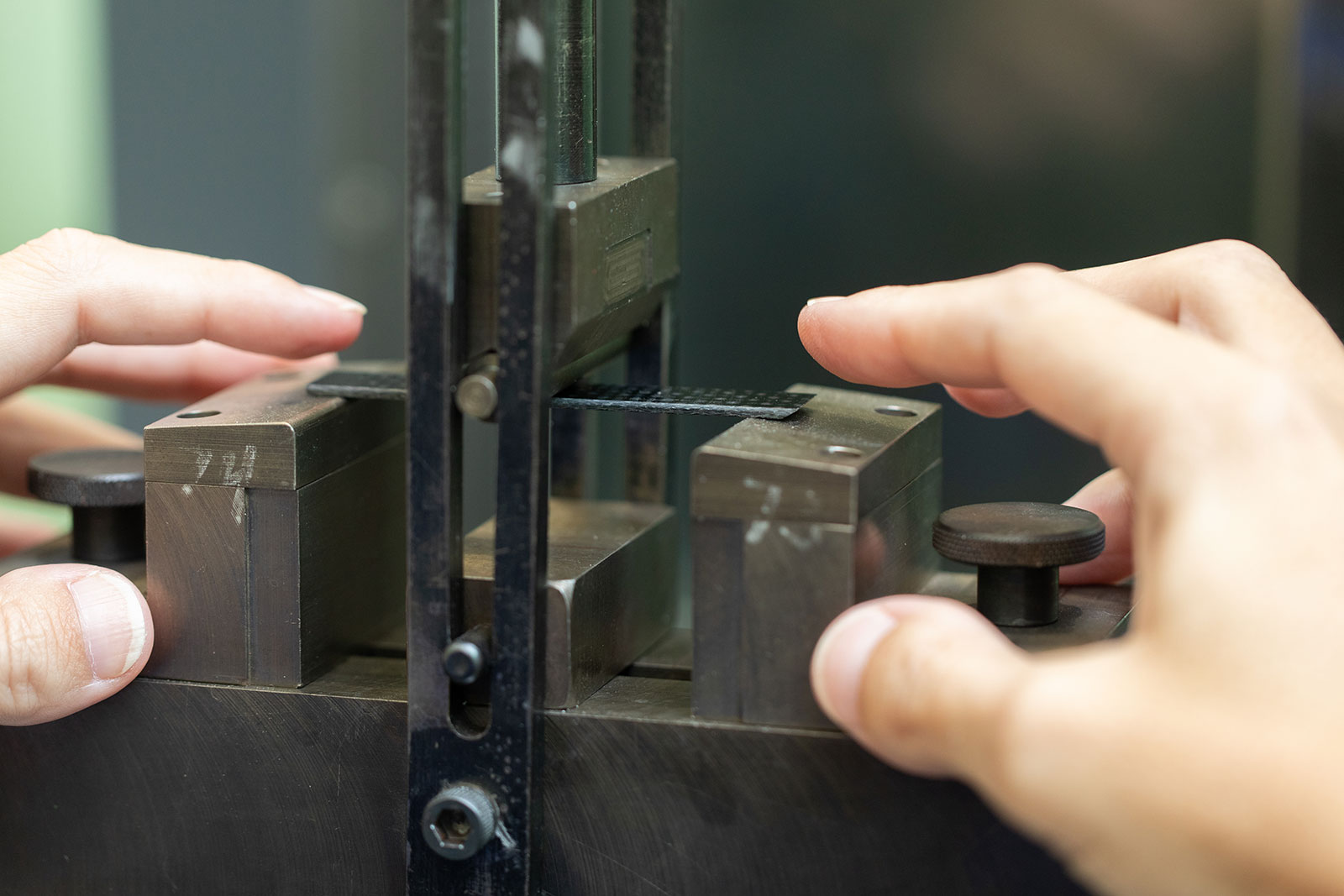

With this endorsement, certain blades and blade holders manufactured by Kadant U.K. for use in food manufacturing processes carry the HACCP International Certification Mark. HACCP International provides certification for products, materials, and services brought into food processing and handling which meet best practices in terms of food safety. This independent conformance certification provides validation of a product’s ‘fitness for purpose’ within food processing and handling applications.

Certified food-safe products manufactured by Kadant U.K. include the AccuFlake™ PRO and AccuClean™ blade holders; VeriTek™, Polyflex™, ProFlake™, SteelFlex™, Stainlessflex™, and Stainless Steel HTSS™ blades; and the VeriLite™ and VeriKleen™ roll cleaner assemblies. Select blades are also available with a proprietary release coating which prevents build-up and contaminants from sticking to the blade and facilitates cleaning.

View certificate for blades

View certificate for blade holders

ISO 9001:2015

As an ISO 9001 member Kadant strives to continuously work to these practices. ISO 9001 is a globally recognized standard for quality management. It helps organizations of all sizes and sectors to improve their performance, meet customer expectations and demonstrate their commitment to quality. Its requirements define how to establish, implement, maintain, and continually improve a quality management system (QMS).

Heritage

Kadant U.K. Limited continues the development and innovation today that established Vickery’s Limited as a market leader.