kConnect series

The kConnect™ series is a group of smart-connected products and services designed with process industry manufacturing in mind, creating a simple but rich user experience. The kConnect series provides access to real-time data of metrics important to the machine’s health.

KCONNECT BLADE CABINET

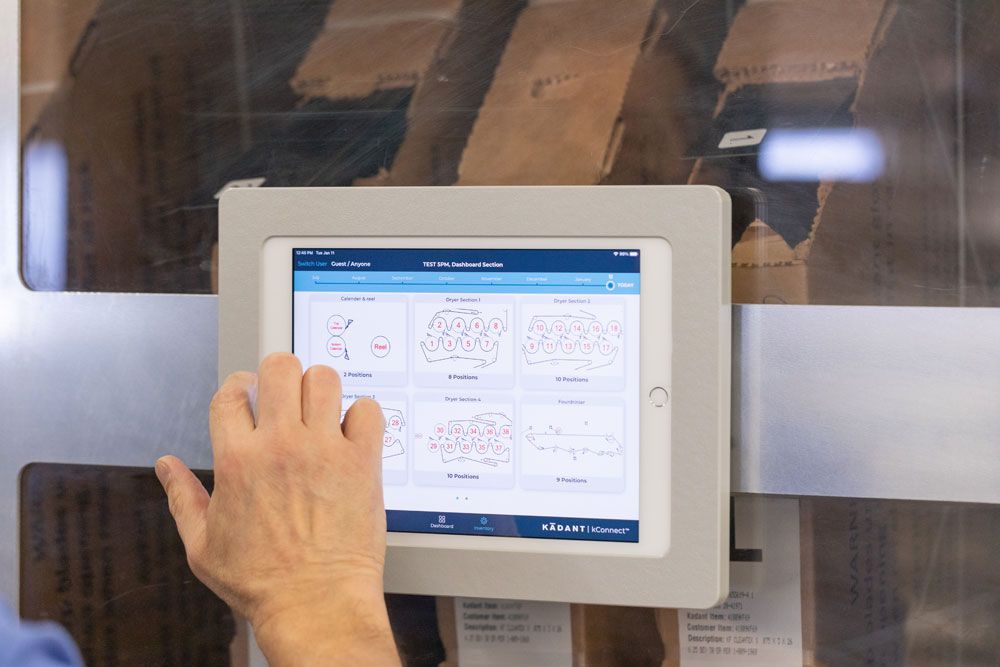

The kConnect blade cabinet provides a smart-connected solution for doctor and roll cleaning blade storage and inventory management all in one. The kConnect blade cabinet creates one, compact place to store blades while using RFID technology to track inventory and automatically order replenishment consumables when the stock is depleted to the mill’s minimum levels. Each blade box is marked coinciding with the machine maps to make tracking blade changes simpler and safer.

Features

- Customized iPad for easy inventory tracking

- RFID technology for blade inventory management

- Machine maps to visually depict blade location

- Track blade placement and location

- Access through the Kadant Access Portal (coming soon)

Benefits

- Improved safety

- Storage for all machine blades is in one location

- Dispensing boxes are controlled and reduce box quantities

- Easy access during downtimes

- Software updates managed and completed remotely

- Possibility of eliminating storeroom inventory

M-CLEAN™ PRO with KCONNECT

The M-clean PRO with kConnect offers intelligent monitoring that leads to insights about preventative maintenance and predictive monitoring for the system. The kConnect series uses a variety of sensors incorporated into the M-clean PRO for monitoring and analysis. The data collected can be used to optimize preventative maintenance to improve performance and reduce downtime.

Kadant Solutions provides general guidelines for how long parts and components should last; however, tapping into the kConnect sensors attached to the M-clean PRO allows for more precision with preventive maintenance. Over time, the intelligent system will enhance optimization of the timing of preventative maintenance, reducing operating costs.