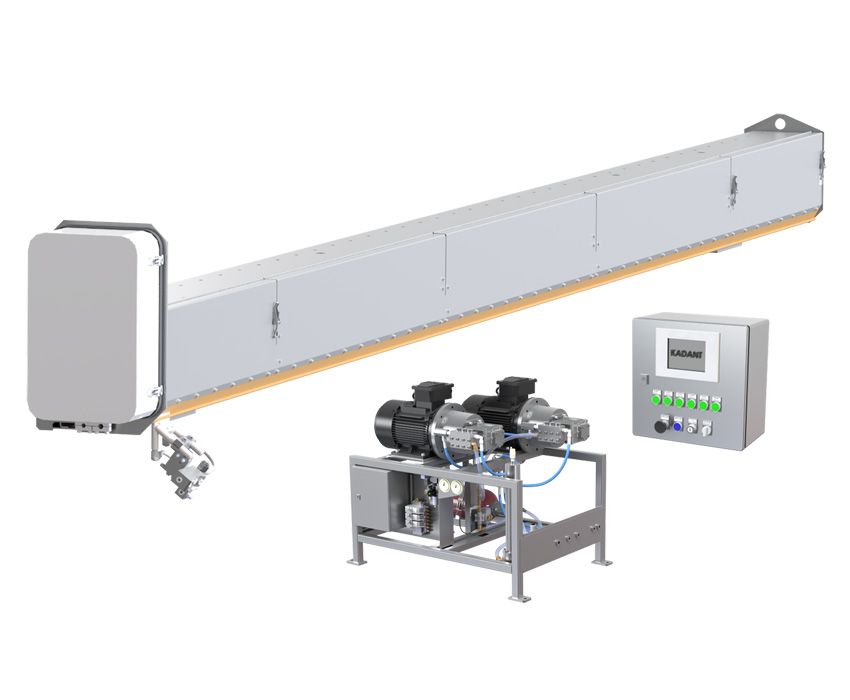

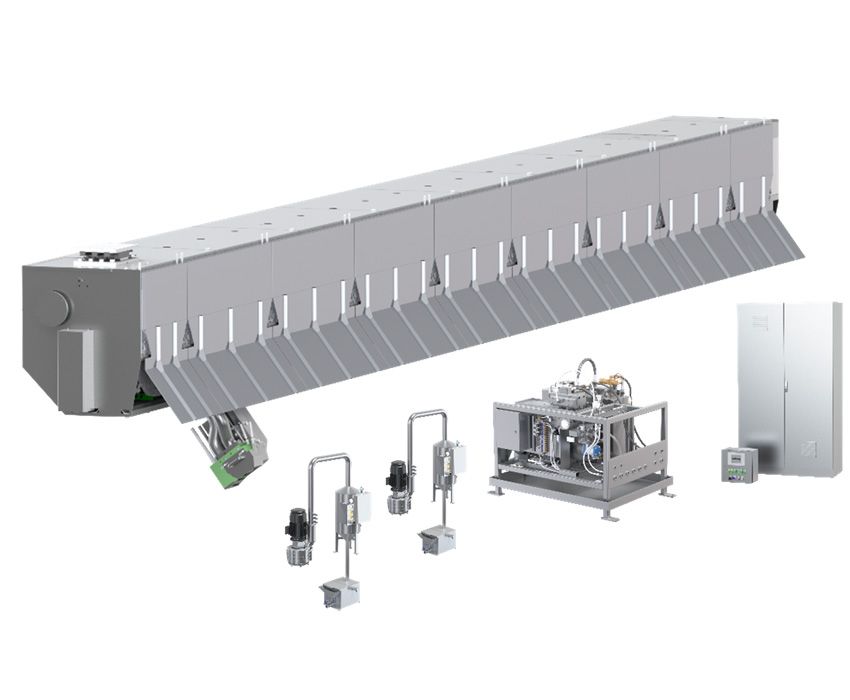

M-clean™ BRUSH

The M-clean BRUSH uses the same method of high-pressure water, evacuation, and air knife system as the M-clean PRO and works in combination to remove impurities, dried out coating color residues, and roll contaminants. Additionally, it has a rotating brush which is an integrated part of the cleaning head for removing contaminants from the roll surface. The cleaning head includes double nozzle bodies for shock cleaning during breaks and continuous cleaning. Current applications include, but not limited to process industries such as paper, nonwovens, fiberglass mat, wood paneling, food processing.

Features

-

Stainless steel construction

-

Designed for up to 160° F (70° C) ambient temperature (higher temperature available upon request)

-

One central unit for up to four cleaning units

-

Efficient cleaning with up to 5,800 psi (400 bar) water pressure

-

Integrated rotating brush with evacuation

-

Smart loading for roll cover protection

-

Spot cleaning functionality

-

kConnect™ series compatibility

-

Single or dual vacuum options available

Benefits

-

Improved machine runnability and production quality

-

Efficient, gentle cleaning of roll surface contamination during production

-

Eliminates manual cleaning for operator safety

-

No moisture is left on the roll surface

-

Simple, low-cost maintenance