Roll Cleaning Technology for a Wide Range of Applications

Kadant has developed and patented roll cleaning solutions for 90 years. During this time, the company developed a wide range of blades for a variety of roll surfaces. Today, the latest roll cleaning technologies feature various pad materials for cleaning and conditioning roll surfaces.

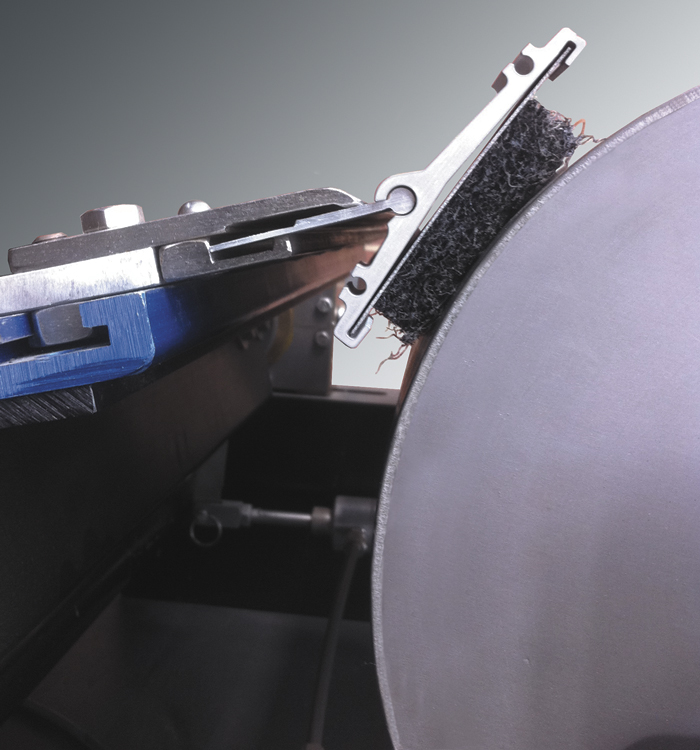

The EzKleen™ roll polisher was developed to clean and recondition process rolls. The simple device incorporates a pivoting shoe that holds a cleaning pad and adjusts to any roll diameter. In addition, the device is made the same length as the roll, so it cleans the entire face of the roll rather than sections of the roll.

The EzKleen™ roll polisher was developed to clean and recondition process rolls. The simple device incorporates a pivoting shoe that holds a cleaning pad and adjusts to any roll diameter. In addition, the device is made the same length as the roll, so it cleans the entire face of the roll rather than sections of the roll.

The pads are made from a synthetic nonwoven material with evenly distributed abrasive particles. The pad’s open design allows it to capture and retain debris being removed from the roll surface. The compressible pad ensures uniform contact on uneven roll surfaces. There is a wide range of abrasive particles and grit sizes, from 80 up to 1,000, allowing the pads to handle a wide range of cleaning applications from removing the harshest baked-on sticky contaminants to fine haze build-up on porous roll surfaces. The pads can be used on all roll surfaces from hardened metal surfaces to soft polyurethane covers.

This EzKleen roll polisher can be used for short periods during downtime or continuously during operation to quickly restore contaminated roll surfaces to an as-installed condition. For smooth metallic roll surfaces, like those used in the metalsprocessing industry, the device can keep the roll surfaces free of debris and maintain the roll’s surface roughness, which is critical to the final quality of the product.

In one particular case, the smooth roll surface degraded from 1 RA to greater than 12 RA over a few days of operation. Running the EzKleen roll polisher for 30 minutes restored the roll surface to its original RA values. This saved the plant the time and cost associated with removing the roll from the machine, reconditioning the roll, and placing the roll back into service. The plant is now able to leave the roll in the machine and safely condition the roll surface in place.

After

After

Before

Before

Another plant had issues with a heated roll surface becoming contaminated with sticky debris even though the plant continuously doctored the roll using a doctor blade. The debris affected production over time as the roll was not able to transmit heat effectively and caused quality defects in the manufactured product. The roll had to be manually cleaned using chemicals, and hand scrapers and brushes, which often caused damage to the roll surface. The EzKleen roll polisher allowed the plant to safely and quickly clean the entire roll surface resulting in decreased downtime and improved product quality.

Yankee After

Yankee After

The EzKleen roll polisher can be used in a variety of industries and applications including metals (galvanizing lines, pickling lines, rolling mills), drum flaking, roofing shingle lines, converting, corrugating, paper, and tissue.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.