In Mill Design™ Service with 3D Laser Technology is Essential for Your Mill

I sat down with Casey McDaniel to better understand In Mill Design (IMD) service and the benefits for pulp and paper mills. Nothing is more valuable than hands-on experience from an expert. Casey is the technical services director at Kadant Solutions with more than 15 years of mill experience.

I sat down with Casey McDaniel to better understand In Mill Design (IMD) service and the benefits for pulp and paper mills. Nothing is more valuable than hands-on experience from an expert. Casey is the technical services director at Kadant Solutions with more than 15 years of mill experience.

V: What is In Mill Design service or IMD?

C: In Mill Design service is when the district sales manager, design, and/or application engineer works with mill personnel on-site to develop customized options for doctoring, cleaning, filtration, and forming systems. Often IMD is used for a critical position such as press rolls, center press, and the Yankee; however, it can be extremely beneficial for all projects.

V: Can you walk me through an average IMD service call?

C: First, we start with a kickoff meeting with all personnel involved in the project. During this meeting, we discuss initial design ideas and define the project scope. This provides a good road map for the shutdown the next day. Next, at the shutdown, the engineer works with mill personnel to collect measurements and data to aid in the design. After the shutdown, the engineer develops the design. Finally, a review meeting is scheduled with all personnel involved with the project to discuss the design and begin the approval process.

C: First, we start with a kickoff meeting with all personnel involved in the project. During this meeting, we discuss initial design ideas and define the project scope. This provides a good road map for the shutdown the next day. Next, at the shutdown, the engineer works with mill personnel to collect measurements and data to aid in the design. After the shutdown, the engineer develops the design. Finally, a review meeting is scheduled with all personnel involved with the project to discuss the design and begin the approval process.

V: What are the expectations of the mill during an IMD service call?

C: For the mill to reap all the benefits of IMD service, it’s essential the mill’s project production, engineering, and maintenance teams are present for the kick-off and review meetings. This allows for the greatest amount of collaboration between our service team and mill personnel. From our perspective, the process goes much smoother if you have key people engaged from the start.

V: How does IMD differ from a decade ago?

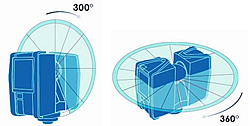

C: In Mill Design service began 15 years ago and has changed dramatically with the development of 3D laser scanning technology. A decade ago, the district sales manager would take the mill dimensions and send them to the engineer to decipher and then customize a design without seeing the application. Today, engineers can conduct a 360° scan of equipment to produce an immediate 3D model. Not only does this provide more accuracy, it cuts time from weeks to days in terms of presenting design options.

C: In Mill Design service began 15 years ago and has changed dramatically with the development of 3D laser scanning technology. A decade ago, the district sales manager would take the mill dimensions and send them to the engineer to decipher and then customize a design without seeing the application. Today, engineers can conduct a 360° scan of equipment to produce an immediate 3D model. Not only does this provide more accuracy, it cuts time from weeks to days in terms of presenting design options.

V: What have been the biggest benefits of In Mill Design service that you’ve witnessed in the field?

C: Overall, the biggest benefit of IMD is the elimination of major fit-up mistakes when the mill goes to install the new equipment. Because collaboration is the focus of IMD, mill personnel can see how the equipment will operate and can voice their thoughts and opinions right away. This significantly cuts down on lead time for the entire project.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.