Causes of Yankee Chatter in Tissue Production

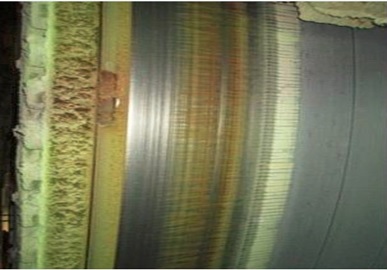

Chatter on a Yankee is a result of multiple process and mechanical issues in the manufacturing of tissue that cause the doctor blade to skip or flex, and eventually bounce on the dryer surface digging into the metal and leaving chatter marks. Chatter issues have plagued tissue makers for decades, causing substantial losses in production and profitability. When chatter becomes an operational problem and there is a need to grind the Yankee to eliminate the defect, expect up to a week of downtime. Surface refinishing is an activity that is costly in labor, lost production, and grinding service.

Chatter on a Yankee is a result of multiple process and mechanical issues in the manufacturing of tissue that cause the doctor blade to skip or flex, and eventually bounce on the dryer surface digging into the metal and leaving chatter marks. Chatter issues have plagued tissue makers for decades, causing substantial losses in production and profitability. When chatter becomes an operational problem and there is a need to grind the Yankee to eliminate the defect, expect up to a week of downtime. Surface refinishing is an activity that is costly in labor, lost production, and grinding service.

Some mills grind the Yankee regularly ranging from every 12 months to five years for a cast iron surface. As the Yankee is ground, metal is removed. Once the thickness of the shell reaches a certain point, the insurance carrier will decide the Yankee’s future. At this point, the decision is made to grind again and “de-rate” the pressure vessel to a lower maximum operating pressure or metalize the surface and keep the same operating maximum pressure. Most mills will metalize the Yankee surface and keep the pressure rating.

Some mills grind the Yankee regularly ranging from every 12 months to five years for a cast iron surface. As the Yankee is ground, metal is removed. Once the thickness of the shell reaches a certain point, the insurance carrier will decide the Yankee’s future. At this point, the decision is made to grind again and “de-rate” the pressure vessel to a lower maximum operating pressure or metalize the surface and keep the same operating maximum pressure. Most mills will metalize the Yankee surface and keep the pressure rating.

Metalizing is an expensive and lengthy process that can take a full week to complete. A properly managed metalized Yankee will run 10 to 15 years before needing a new metallization.

The influences on chatter generation are infinite, but with proper management, many sources of chatter can be eliminated or controlled. When the tissue maker says, “We have chatter,” it is bad news for some suppliers and good news for others. One thing is for sure, changes should be made.

The influences on chatter generation are infinite, but with proper management, many sources of chatter can be eliminated or controlled. When the tissue maker says, “We have chatter,” it is bad news for some suppliers and good news for others. One thing is for sure, changes should be made.

The easiest factors to change are the Yankee chemistry or blade supplier. However, rarely will changing the Yankee chemistry or blade supplier solve the problem alone. As mentioned earlier, a chatter problem has multiple sources, and eliminating or controlling one or two factors will not necessarily fix the issue. Let’s examine the major sources of vibration and how they can interact to cause chatter.

Major Sources of Chatter Causing Vibration

Chemistry Yankee chemistry is designed to protect the Yankee and allow the sheet to be creped at the proper amount of intensity to produce tissue with the desired properties. The Yankee chemistry is hard to visualize, but if you think about a simple box as an “operating envelope”, the coating works best when it is operating inside that box. The Yankee surface is quite dynamic due to multiple process changes and constant blade wear. When the process is allowed to force operations out of the normal creping envelope, the Yankee becomes at risk for chatter.

Yankee chemistry is designed to protect the Yankee and allow the sheet to be creped at the proper amount of intensity to produce tissue with the desired properties. The Yankee chemistry is hard to visualize, but if you think about a simple box as an “operating envelope”, the coating works best when it is operating inside that box. The Yankee surface is quite dynamic due to multiple process changes and constant blade wear. When the process is allowed to force operations out of the normal creping envelope, the Yankee becomes at risk for chatter.

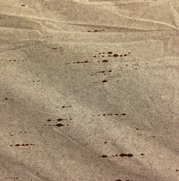

The picture to the right illustrates “moon rock” on the edges. There are two hard bands of material too difficult to evenly remove with doctors. This region can easily develop into chatter. Without immediate action, this pulse will propagate the length of the doctor and cause chatter under the sheet.

The picture to the right illustrates “moon rock” on the edges. There are two hard bands of material too difficult to evenly remove with doctors. This region can easily develop into chatter. Without immediate action, this pulse will propagate the length of the doctor and cause chatter under the sheet.

Why is the material only here? The extra heat outside the sheet is too high for the coating. It dries very hard and cannot be removed with the underperforming doctoring equipment and materials.

Why can’t the coating just be fixed? The coating is designed for under and outside the sheet, so compromises have to be made for production. In some cases, the tissue maker will dry up the sheet on a dry crepe machine to get more bulk or softness from lower moisture. In this case, the higher heat is outside the operating envelope and a heavy coating covers the Yankee making it difficult to properly doctor. On the other extreme, if the Yankee operates too fast and the chemistry does not have enough time to properly set (40 to 60 milliseconds) before the chemistry is washed off, poor creping and inadequate Yankee protection occur.

Process chemistries also present challenges to proper Yankee operation. Debonders, softeners, and defoamers soften the coating. Wet strength, dry strength, carboxymethyl cellulose (CMC), and temporary wet strength make the coating more robust. Ionic trash, sulfites, pH changes, and oxidizers all negatively influence the Yankee coating and must be addressed to keep control of the Yankee surface.

To properly manage the Yankee surface, tissue makers have several tools to keep the process within the proper envelope. One important tool is adding phosphate in the boom shower to create a better “stick” to the Yankee. Mono Ammonium Phosphate (MAP) is quite common on metalized Yankees and can be fed to decrease the boom pH. This reduces the speed of reaction and softens the coating, or adds a high pH phosphate to increase the reaction rate of the adhesive resin. The reaction speed controls the film thickness on the Yankee. If a modifier is substituted for an oil release, the reaction rate of the film formation will increase, as will the film thickness. Proper ratios are necessary to keep the Yankee safe from chatter formation scenarios.

Doctors

Doctors can be a major source of vibration leading to Yankee chatter. Typically, machines use two to three doctors. All doctors must be monitored closely when chatter is evident. Doctors generate chatter in many ways including pulses from the oscillation equipment. If a doctor is poorly fit to the Yankee, the Yankee coating will be uneven and the protection will be inadequate in some areas. Under or overloading the doctor, improper blade angle, or bevels will cause the Yankee surface to not be properly cleaned and compromise protection from the organic coating. Certain machine doctor setups have doctor loading procedures that can cause damage from a load cycle that is too rapid and the Yankee can be damaged or gouged. Some finger-type doctor blade holders have a reputation of causing what is known as “Tiger Stripe” and are not recommended for high speeds.

Excessive Moisture and Uneven Moisture Profiles

One of the more difficult areas for tissue makers to troubleshoot during Yankee operation is the condensate removal system because most of its operation is not visible. More likely than not, instrumentation is lacking or poorly maintained leading to unreliable information and “drying blind.” If the Yankee becomes too hot, it can “go square” leading to pressure roll bounce and massive vibration forcing the Yankee to cool too quickly or shut down. This type of vibration is heavy and dangerous. Other issues that can result include non-uniform shell temperatures that lead to hot and cold spots typically caused by localized siphon plugging or internal leaks and the improper operation of the dryer drainage system. In modern dryer drainage systems, blow-through steam is used along with managed differential pressure control to remove condensate.

An uneven moisture profile is a factor in the majority of chatter events. Wet streaks can wash off the Yankee coating and eliminate the protection for that area of the Yankee. Dry streaks cause a heavy coating due to the higher temperature and result in a heavier coating that cannot be removed evenly. Wet streaks next to dry streaks are a major source of poor blade wear and increased vibration. The suction pressure roll (SPR) is another major source of uneven moisture profiles. A worn SPR will dewater at a significantly different rate. And, if the doctoring of the water sling off the roll is inadequate, the unremoved water will flood certain sections of the nip resulting in uneven moisture profiles.

Clothing Performance After break in, the Yankee clothing performance will deteriorate through a normal life cycle. The clothing must be replaced after some period and the cycle repeats. As the clothing operates, it picks up soils and other contaminants that limit its ability to properly dewater at the nip causing the sheet to the Yankee to get wetter. A wetter sheet may cause too much cooling on the Yankee and the coating is, in turn, not properly set and protection is reduced.

After break in, the Yankee clothing performance will deteriorate through a normal life cycle. The clothing must be replaced after some period and the cycle repeats. As the clothing operates, it picks up soils and other contaminants that limit its ability to properly dewater at the nip causing the sheet to the Yankee to get wetter. A wetter sheet may cause too much cooling on the Yankee and the coating is, in turn, not properly set and protection is reduced.

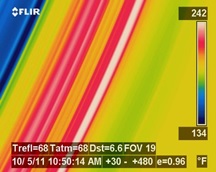

The thermal image to the right shows how the wet felt will cool the Yankee surface just outside the sheet (the middle orange band between the red zones). This cooler strip, in most cases, will contact the felt and this free water will cool the area and wash off any organic coating in this region allowing for excessive blade wear and eventual blade chatter outside the sheet. Since felts vary in width over time, this zone will move and must be watched closely to prevent chatter initiation. Proper felt widths must be used to match the internals of the Yankee. Edge showers may be needed to control edge build ups.

Poor Pressing

Tissue making suffers from the effects of poor pressing just like other paper grades. Generally, modern machines use one press, the single press roll (SPR), but many still have a second press that may or may not be loaded. As the SPR ages, the rubber gets thinner and harder. As the P&J hardness of the SPR falls into the low 30’s, the nip may become too intense for proper operation. Another major issue for the SPR is the proper adjustment of the water sling off the vacuum zone. Improper adjustment of the SPR will increase the water carried into the nip from water missing the pan. If the machine is designed for a second press and is unloaded, the Yankee deformation is changed and the crown curves of the SPR are likely incorrect. A poor fitting SPR will cause wet streaks and the Yankee protection is threatened.

Speed

Speed is often a root cause of chatter. If operating too fast for the process, the sheet can be too wet and/or streak causing uneven film formation on the Yankee and inadequate protection. Running too slow is also a source of excessive vibrations from heavy coatings on the Yankee. “Limping” a Yankee at low speed without major changes in the chemistry is very difficult to do safely. Many machines will experience periods of massive vibrations from harmonics in the rolls, Yankee dryers, and doctors at varying speeds. As the Yankee runs faster, harmonics are an issue that must be addressed at speeds specific to each Yankee.

Tools to Measure Vibrations and Yankee Coatings

Vibration monitoring systems are available to measure the vibrations on the doctors with accelerometers. A stream of data is continuously fed into programs that help develop operating conditions and procedures to control and reduce vibration.

Other trending information from the DCS and Yankee torque curves are very useful in comparing different chemistry packages and operating conditions. The torque is sensitive to speed, moisture, and coating film thickness and hardness. Measuring blade wear rates and angles will also help close the gap in finding the best and safest place to operate the Yankee dryer for tissue manufacture.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.