Prevent Fibre Wraps with a Roll Cleaning Solution from Kadant

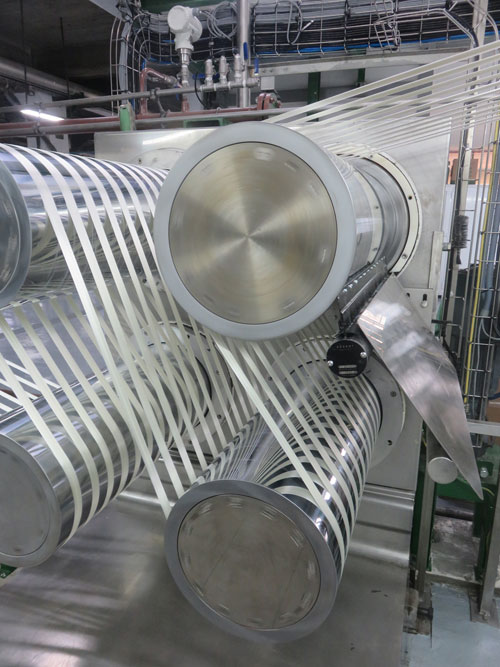

Some call them draw stands or stretching stands while others call them spinner rolls or godet rolls. Regardless of the name, if you are a synthetic fiber producer, a few things are true:

Some call them draw stands or stretching stands while others call them spinner rolls or godet rolls. Regardless of the name, if you are a synthetic fiber producer, a few things are true:

- The fiber must be stretched to the desired denier.

- Process upsets associated with broken or loose fibers wrapping rolls must be dealt with.

- Rolls are manually cleaned before starting the next production run.

For years, the industry standard for roll cleaning and wrap prevention was to use a bulky piece of equipment that allowed a pad or brush assembly to be loaded perpendicularly to the roll. Although effective at removing light haze build-up or polishing the roll, pads are typically less effective at preventing fiber wraps than blades. At best, pads serve as a collection point for stray fibers.

Kadant’s VeriLite™ roll cleaner assembly is a lightweight alternative to bulky apparatuses and is ideally suited for safely and reliably cleaning cantilevered rolls. The assembly accepts a variety of doctor or roll cleaning blade materials as well as Kadant’s patented EZ Kleen™ roll polisher pads. With the VeriLite roll cleaner assembly, fiber stretching operations are inherently safer because roll cleaning blades can be easily and quickly removed from the end.

Kadant’s VeriLite™ roll cleaner assembly is a lightweight alternative to bulky apparatuses and is ideally suited for safely and reliably cleaning cantilevered rolls. The assembly accepts a variety of doctor or roll cleaning blade materials as well as Kadant’s patented EZ Kleen™ roll polisher pads. With the VeriLite roll cleaner assembly, fiber stretching operations are inherently safer because roll cleaning blades can be easily and quickly removed from the end.