High-Resolution™ Forming System

The High-Resolution forming system is designed for use with packaging grades of paper.

This three-component system consisting of high-resolution drainage structures, Stepfoil™ technology, and high precision vacuum control provides the papermaker with excellent activity control across broad grade structures and different furnishes while maintaining an open sheet. The simple system with no moving on machine parts provides a robust and reliable system that increases table dewatering capacity and sheet activity control with a low total cost of ownership.

Products

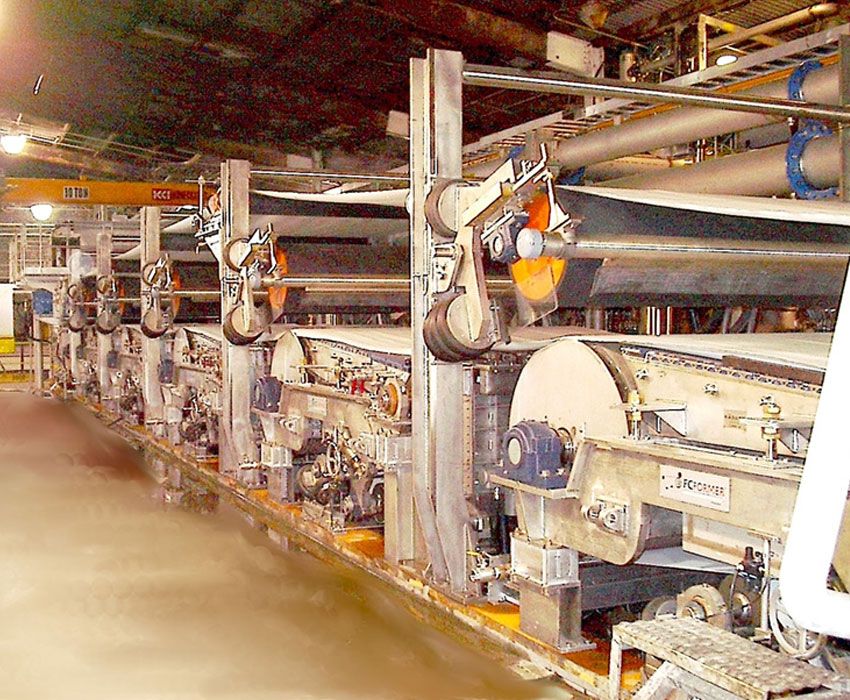

FC Former™ Forming System

Replacing two conventional hydraulic or vat type forming stations, the FC Former forming system can carry a high fiber load and operate at higher speeds than conventional underfelt formers. The unique, patented VID forming technology enhances drainage without sealing the sheet or decreasing retention.

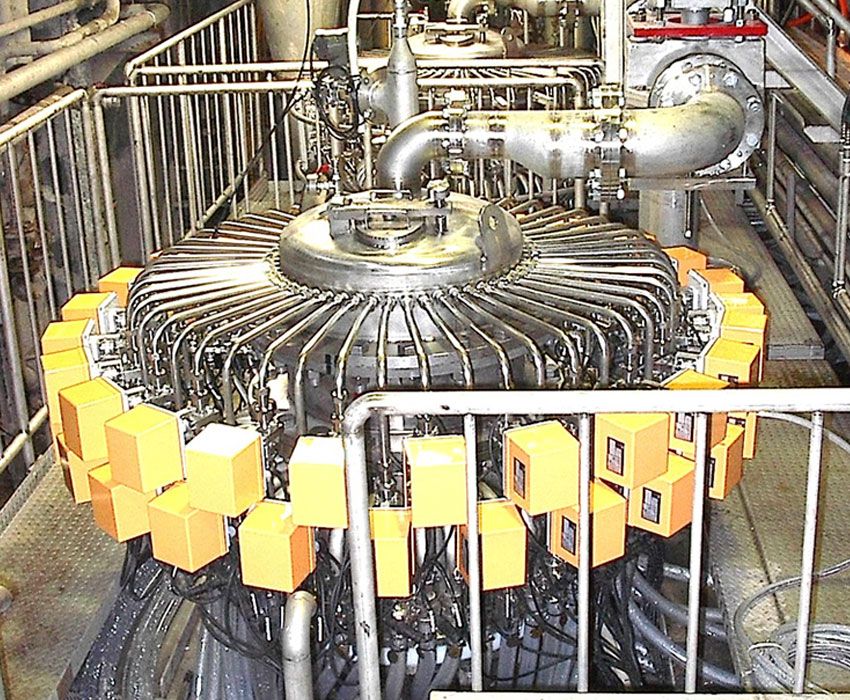

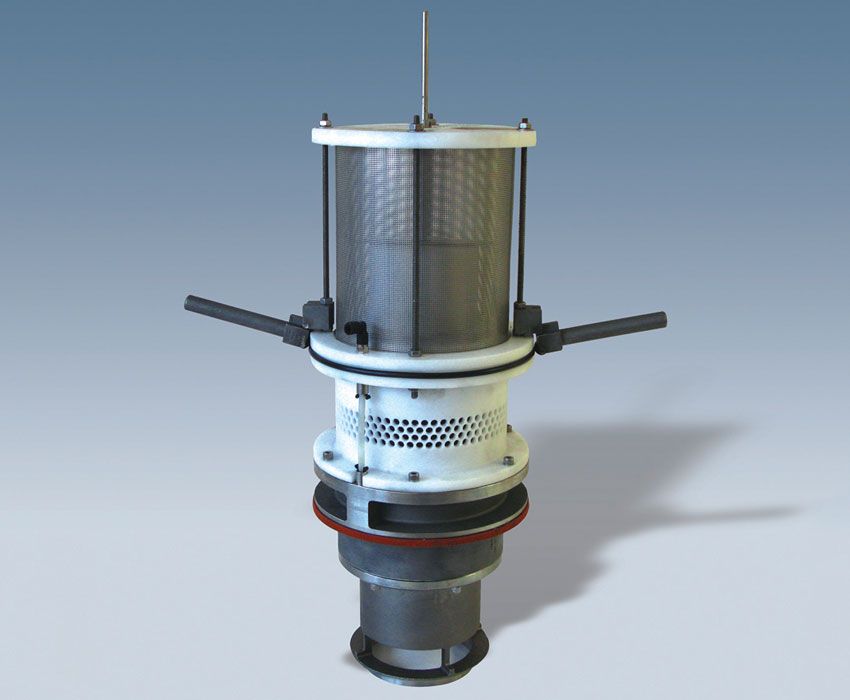

Octopus™ Stock Approach System

The Octopus stock approach system is radial-type distributor that supplies forming devices (vats, hydraulic formers or headboxes) with uniform machine profiles across the width of the machine without the need for header balancing by recirculation. When equipped with consistency profiling ability, the Octopus stock approach system allows the control of CD basis weight profile while paper machines are operating.

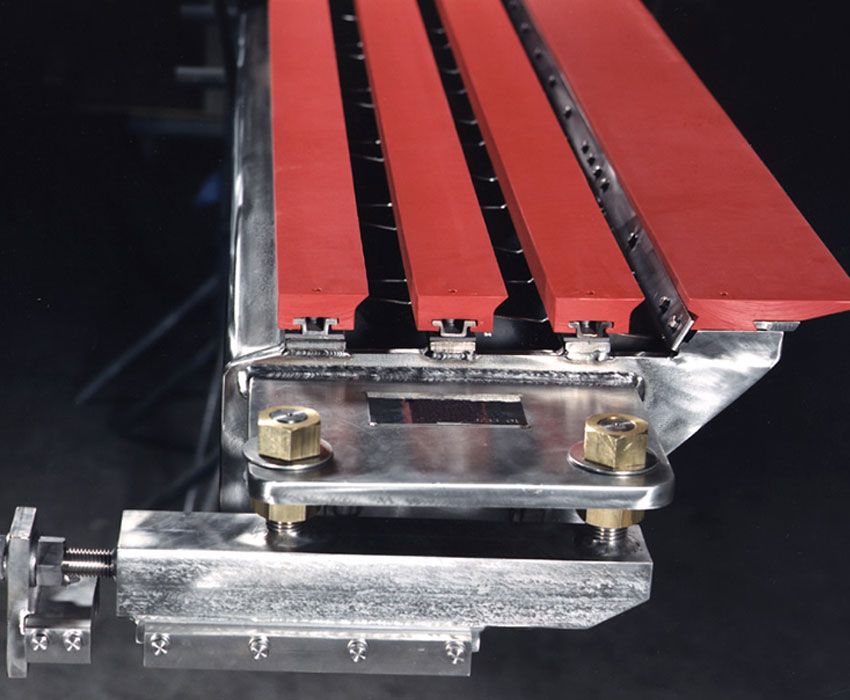

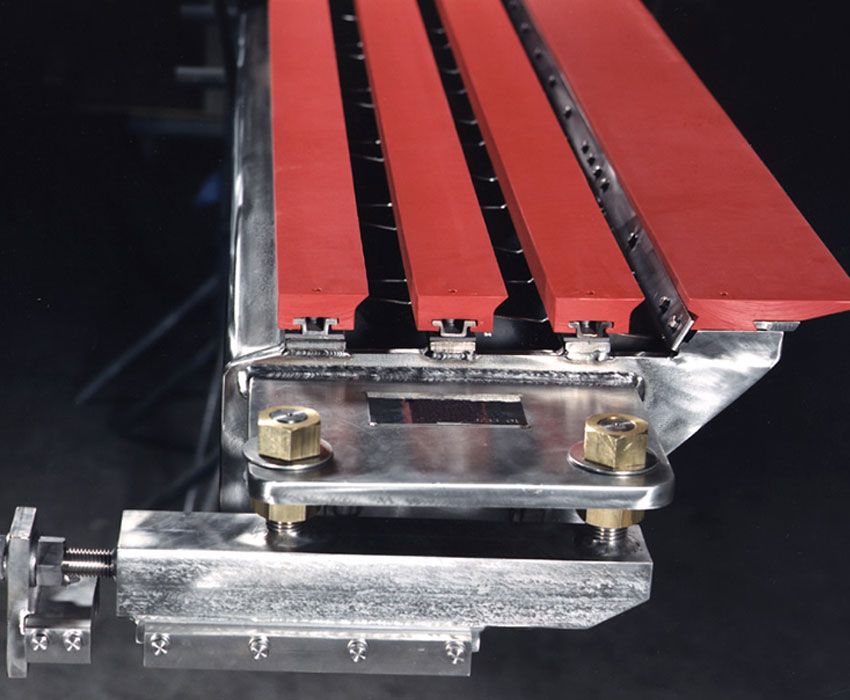

Drainage Structures

Drainage structures are vital to water removal during the papermaking process. We provide drainage structure including forming boards, gravity foils, VID™ forming technology, and high vacuum single or multiple zone flatboxes.

Vacuum Control Systems

Vacuum control systems provide efficient use of energy and precision control of the wet end dewatering process. We offer a complete range of vacuum control components including DCS vacuum interfaces, vacuum control piping systems, single-stage or multiple stage exhausters, and vacuum control valves.

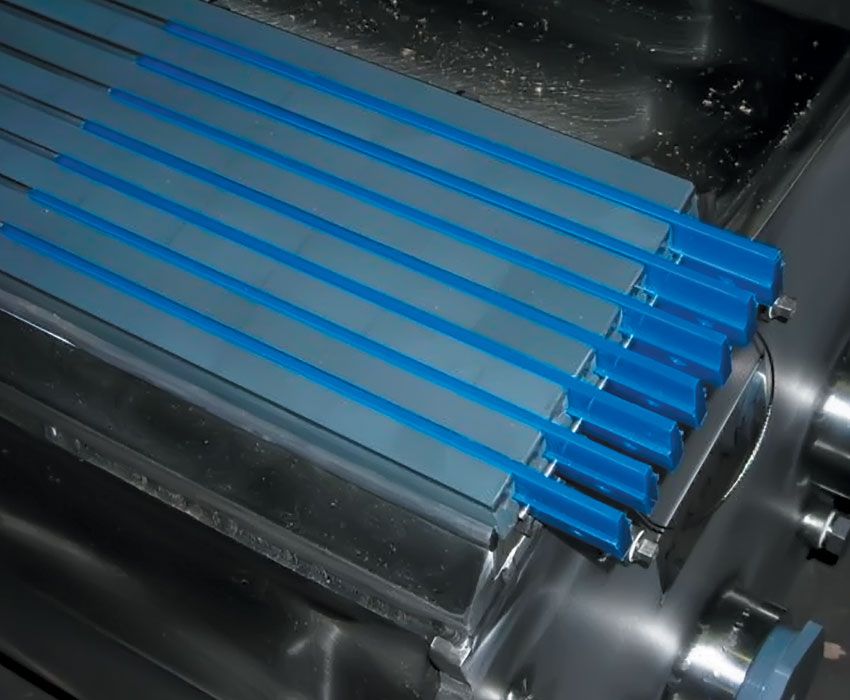

Wear Surfaces

Wear surfaces are one of the most overlooked papermaking components at the wet end. Forming board, gravity and vacuum assisted blades, and flatbox covers that resist wear and maintain their original shape over extended periods of operation ensure that the paper machine has optimum dewatering and activity performance. We offer ceramic and polyethene wear surfaces.