What is a Doctoring Roll Cleaning System: An Interview with Scott Borges

I recently sat down with Scott Borges to learn about doctoring roll cleaning systems. Scott is the Project Manager for Kadant Solutions. Scott has 25 years of doctoring and roll cleaning expertise that he uses to support our entire organization.

I recently sat down with Scott Borges to learn about doctoring roll cleaning systems. Scott is the Project Manager for Kadant Solutions. Scott has 25 years of doctoring and roll cleaning expertise that he uses to support our entire organization.

V: Where did the term “doctor” originate in the paper industry?

S: It’s believed the term “doctor” originated in the early 1900’s by an engineer named Dr. Vickery. He invented the paper machine doctor and the term “doctor” came from his title. Dr. Vickery observed water on roll surfaces as well as fiber accumulation which limited paper machine speed and runability. The doctor blade was invented to remove this excess water and fibers from the roll surface.

V: What is a doctoring roll cleaning system?

S: Doctoring or roll cleaning is an important process that has several basic functions such as removing water and contaminants from the roll surface, cleaning and conditioning the roll surface, and sheet shedding during sheet breaks or threading operations.

V: What components make up a doctoring roll cleaning system?

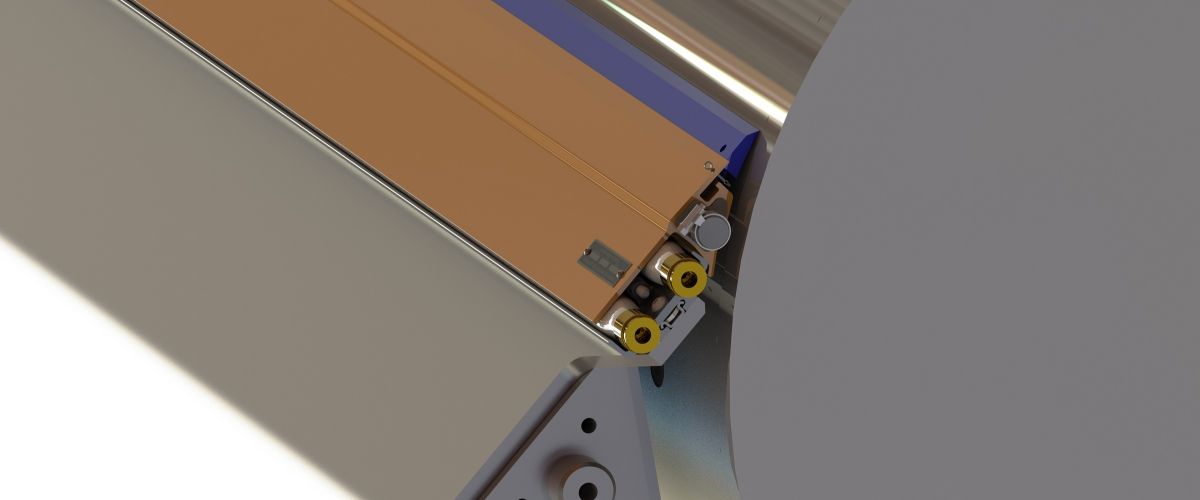

S: A doctoring roll cleaning system consists of the doctor back (i.e., a beam), a blade holder, a blade, and components to mount the system to the machine’s framework. The blade performs the functions of removing water, debris, and contaminants; cleaning and conditioning the roll surface, or shedding the sheet. Blades wear out over time and need to be replaced regularly depending on the application.

Blade material selection is critical for the application, but the other components of the system are just as important to the system’s success. You can utilize the most optimal blade material yet have poor performance if the doctoring system is not adequate for the application.

V: What are some benefits of doctoring roll cleaning?

S: Doctoring or roll cleaning can prevent material from wrapping the roll surface. In applications where a continuous web of product is being produced such as paper, film, fibers, or food, a web break can cause the material to wrap around the roll. Doctoring systems help direct the product, sheet, or web to the next section of the machine. There are also specialty doctoring applications like creping of the sheet, coating, and metering applications.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.