Maximizing Efficiency with Advanced Spray Nozzle Technology

Spray nozzles are used for cleaning fabrics, felts, and wires in various manufacturing processes. High-quality spray nozzles help remove contaminants efficiently, keep production processes running smoothly, and maintain high operational standards.

are used for cleaning fabrics, felts, and wires in various manufacturing processes. High-quality spray nozzles help remove contaminants efficiently, keep production processes running smoothly, and maintain high operational standards.

Spray nozzles are available in several types, such as jet, fan, brush shower, and ruby-tipped, that cater to different cleaning requirements. Unfortunately, spray nozzles can often encounter several challenges that can negatively impact their functionality. Choosing the right spray nozzle size and material, knowing common problems, and performing preventative maintenance can improve operational efficiency and avoid costly downtime.

Common Spray Nozzle Problems

Worn Nozzle

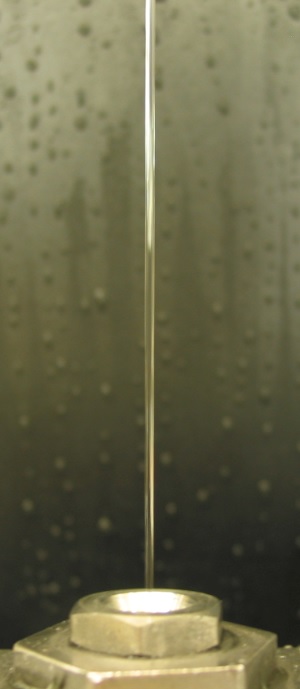

Worn Nozzle New NozzleRegular spray nozzle maintenance is critical to prevent performance degradation. Let’s look at a few common problems associated with spray nozzle operation and preventative maintenance strategies.

New NozzleRegular spray nozzle maintenance is critical to prevent performance degradation. Let’s look at a few common problems associated with spray nozzle operation and preventative maintenance strategies.

- Erosion or Wear

Erosion or wear of the spray nozzle occurs when a liquid under high pressure flows through the spray nozzle orifice repeatedly. This continuous flow gradually removes metal from the orifice, causing it to expand in size. Consequently, the flow rate increases, the pressure decreases, and the spray pattern becomes uneven.

- Corrosion

The spray nozzle body and orifices can corrode depending on the liquid being sprayed and the environment. Choosing the right material for the spray nozzle is crucial when operating in a corrosive environment. For instance, a titanium spray nozzle should be used when spraying bleach.

- Temperature

Certain process conditions may require higher liquid temperatures to improve cleaning efficiency. However, this could lead to accelerated spray nozzle orifice wear due to the softening of the metal.

- Caking or Filler Build-up

The build-up of minerals and fillers from dissolved material, such as iron, can negatively impact the spray nozzle orifice, resulting in a poor spray pattern, increased pressure, and reduced flow.

- Accidental Mechanical Damage

This is the most widespread problem causing poor spray nozzle performance, leading to spray nozzle replacement. It leads to poor spray patterns, increased pressure, and reduced flow.

- Nozzle Orifice Clogging

Unwanted solid particles larger than the spray nozzle orifice can block the hole and cause poor spray patterns, increased pressure, and reduced flow in the water stream.

Spray Nozzle Preventative Maintenance

To avoid these common problems, a proactive approach to spray nozzle maintenance is essential. Kadant Solutions recommends the following.

- Consistent Inspections

Regularly check spray nozzles for wear, clogging, or damage. Early detection helps prevent larger, more expensive issues.

- Prompt Replacement of Damaged Nozzles

Replace spray nozzles immediately if they show significant wear or damage. Delaying this can lead to inefficiencies, increased water usage, lower productivity, and higher costs.

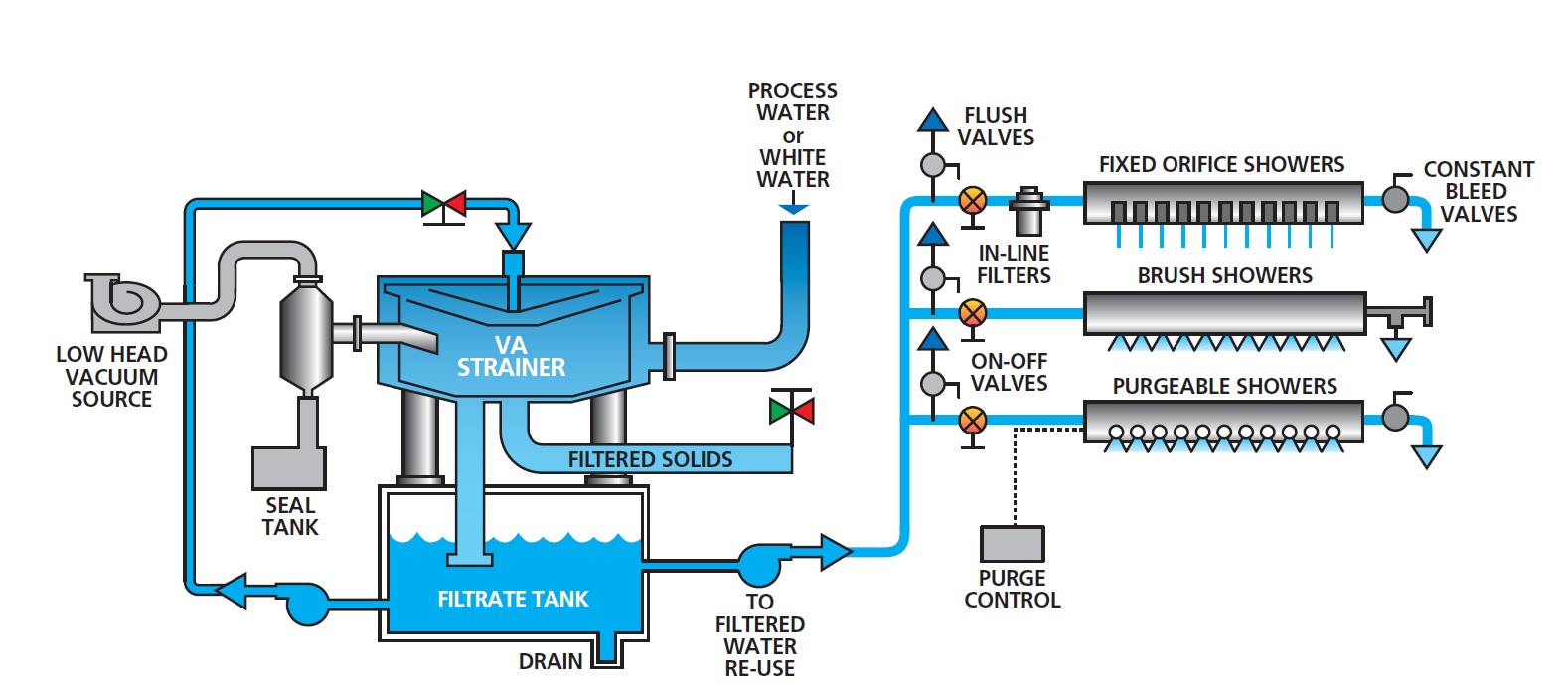

- Effective Filtration Systems

Install filters at the pump inlet and shower inlet to protect the spray nozzle orifice from clogging. Choose from different filter types based on your setup requirements, like a RotoFlex™ resource recovery strainer, gravity strainers, and pressure filters.

- Select the Appropriate Orifice Size

Match the spray nozzle orifice size with your specific needs, considering the solids in the water. Use a correlation table to find the right orifice size, ensuring efficient operation and reduced clogging risk.

- Choose the Right Materials

Use materials that suit your specific operating conditions. In corrosive environments, use durable materials like titanium to reduce the need for frequent replacements.

Spray Nozzle Pattern ExampleOptimized Shower Oscillation

Spray Nozzle Pattern ExampleOptimized Shower Oscillation

For systems with shower nozzles, match the oscillation speed with the machine's speed to ensure even distribution of the spray nozzle energy on the fabric or wire in the cross-machine direction.

- Water Quality Management

Analyze water quality when selecting shower hardware. Cleaner water means fewer blockages in fixed orifice nozzles. In high-solids water, use spray nozzles that can be cleaned during operation, like brush or purgeable showers, or those with internal extensions and screens to manage clogging.

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.