How Does the Conformatic™ AL Creping Holder Work?

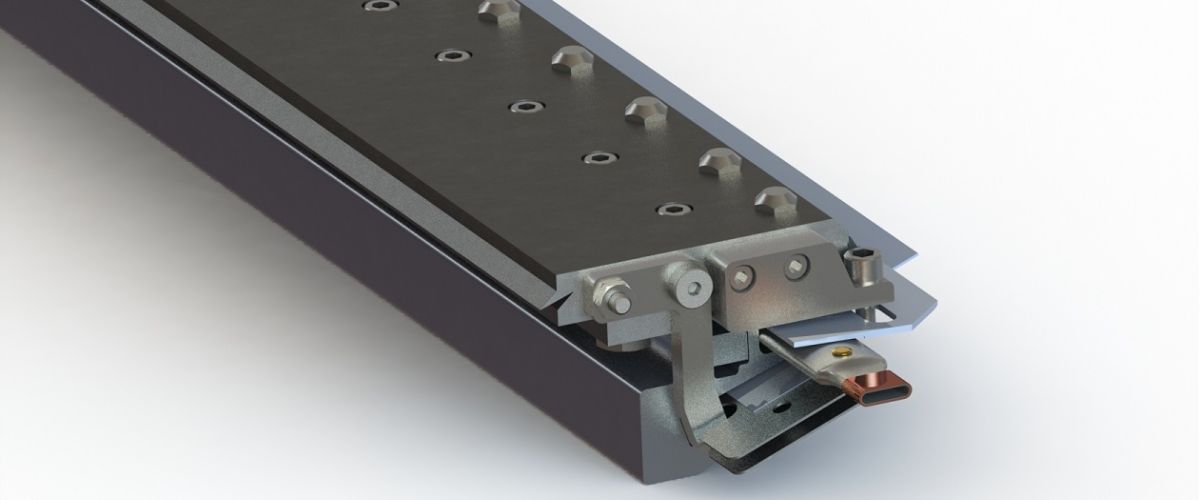

The next-generation Conformatic™ creping holder, the Conformatic AL creping holder, incorporates the latest technology bringing improved blade holder performance to the tissue market. The holder is designed for use in all Yankee doctor positions including cut-off, creping, and cleaning.

According to Jerry Vandoros, director of industrial sales at Kadant Solutions, “The Conformatic blade holder is the industry standard when it comes to tissue making, but we knew it could be even better. With this next-generation model, the Conformatic AL, we focused on features that would make it easier to use and mitigate risk to the Yankee.” Vandoros continued, “The proprietary adjustment mechanism allows for effortless bi-directional adjustment, with enough movement to accommodate even the most extreme Yankee crowns. The modern design uses adjustment screws to maintain the desired positioning and eliminates the need for edge fingers. As the operating duty is extreme, we increased the load capability of the conforming tube and designed a carbon fiber backup blade that eliminates issues caused when using stainless steel blades.”

Significant upgrades to the holder’s adjustability were achieved with a proprietary adjustment mechanism allowing for precise control of the holder profile across the Yankee face. The robust construction is designed for high-performance tissue machines. It features a self-conforming liquid tube, a backup blade, and a quick removal feature that allows the holder to be removed for cleaning and maintenance. Optional “smart” features can be integrated to provide real-time process feedback such as vibration and load. The holder is available in new doctor systems or as a retrofit to existing Conformatic holders.

How does the Conformatic AL creping holder work? To visually illustrate the process, please watch the following video.

Related Articles

Tagged with

Author

Share

Let’s Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.